WHEN

CAM

SHAFT

PROPE

THE

D

ON

DR

AS

INDICATED

CENTER PIN

GOVERNOR C

GOVERNOR

FLY

BAL

U

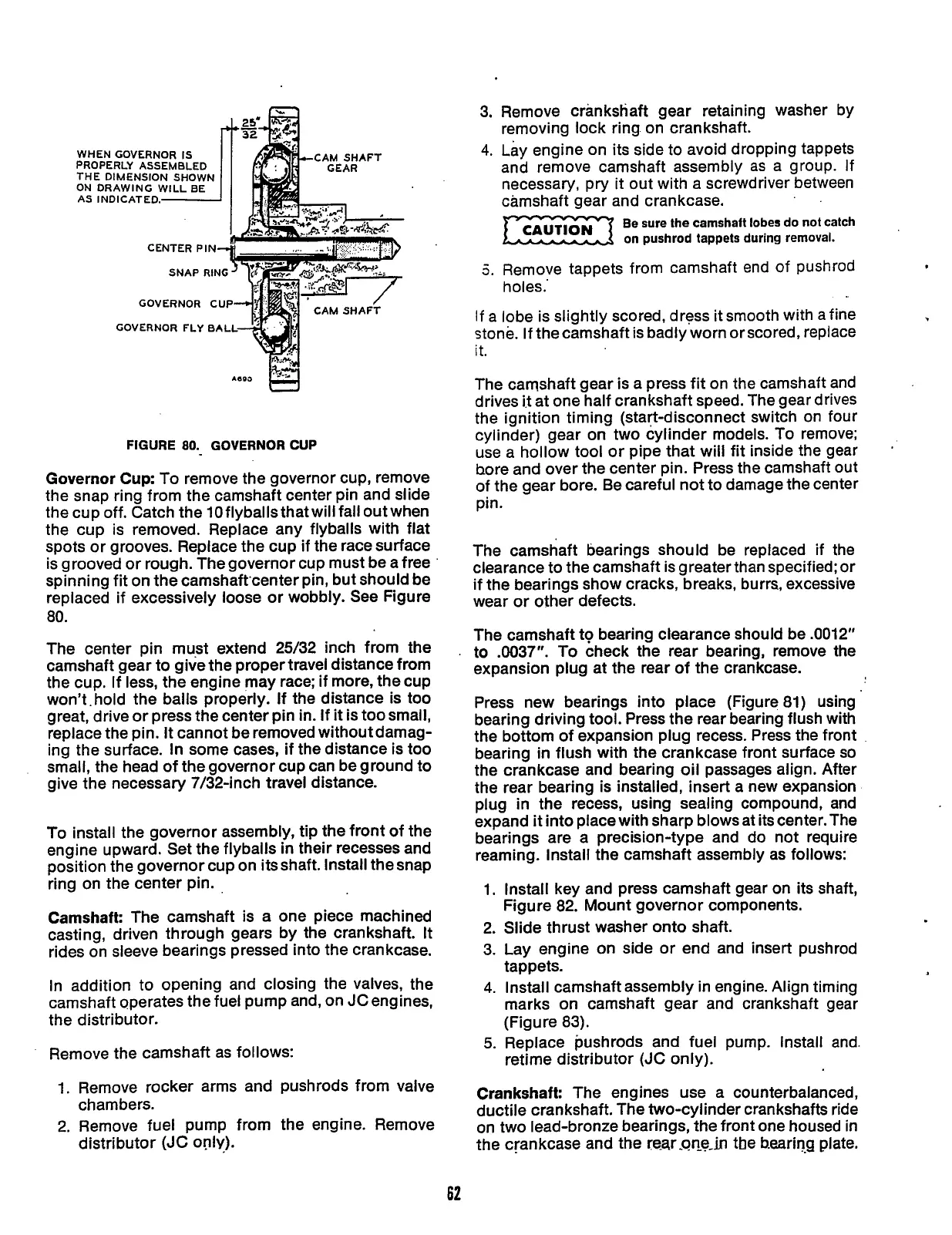

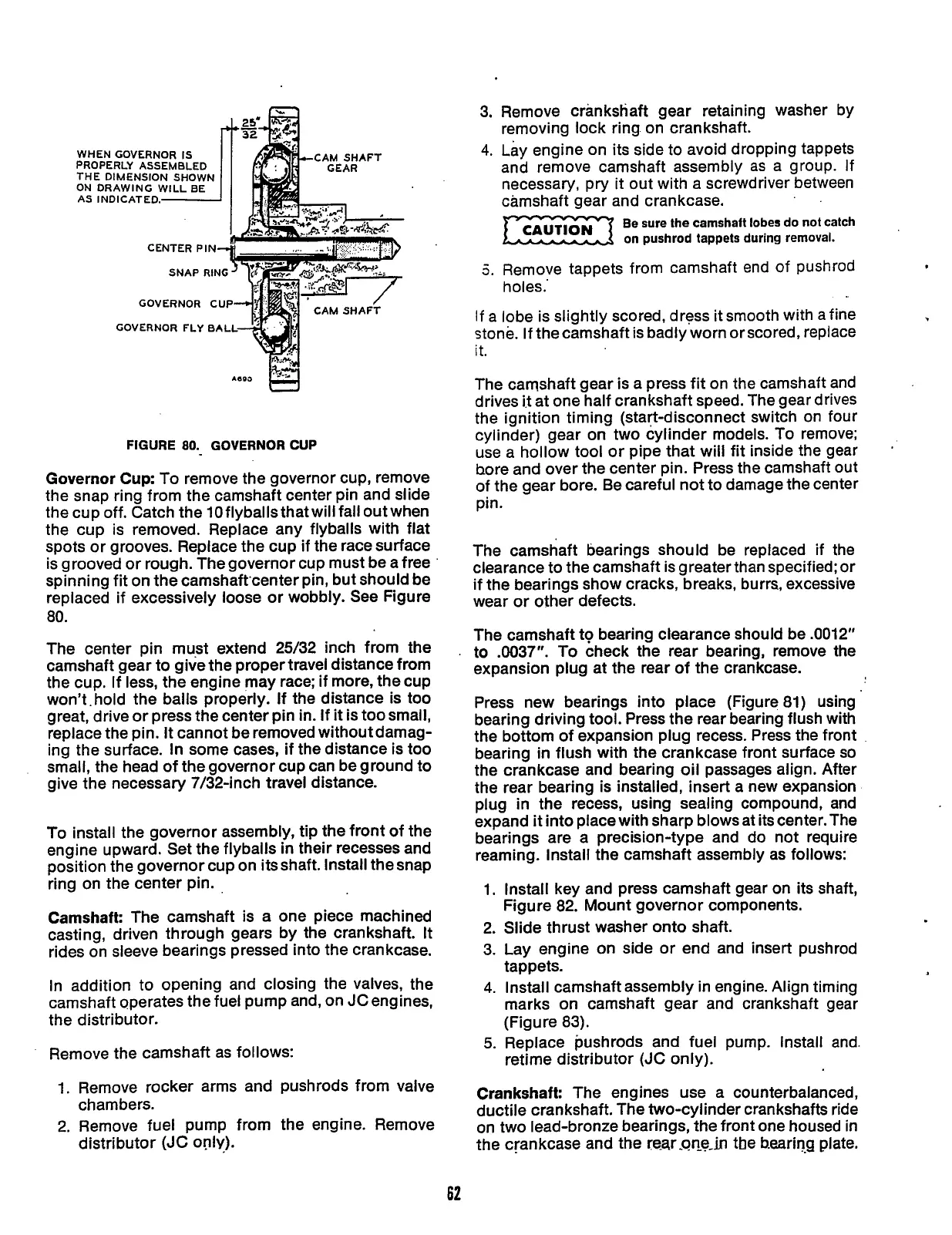

FIGURE

80.

GOVERNOR

CUP

Governor

Cup:

To

remove the governor cup, remove

the snap ring from the camshaft center pin and slide

the cup off. Catch the

10flyballsthatwillfalloutwhen

the cup is removed. Replace any flyballs with flat

spots or grooves. Replace the cup

if

the race surface

is grooved or rough. The governor cup must be a free

'

spinning fit on the camshaft'center pin, but should be

replaced if excessively loose or wobbly. See Figure

80.

The center pin must extend 25/32 inch from the

camshaft gear to give the proper travel distance from

the cup. If less, the engine may race;

if

more, the cup

won't. hold the balls properly. If the distance is too

great, drive or press the center pin in. If

it

is too small,

replace the pin.

It

cannot be removed without damag-

ing the surface.

In

some cases, if the distance is too

small, the head of the governor cup can be ground to

give the necessary 7/32-inch travel distance.

To

install the governor assembly, tip the front of the

engine upward. Set the flyballs

in

their recesses and

position the governor cup on itsshaft. Install thesnap

ring on the center pin.

Camshaft: The camshaft is a one piece machined

casting, driven through gears by the crankshaft.

It

rides on sleeve bearings pressed into the crankcase.

In addition to opening and closing the valves, the

camshaft operates the fuel pump and, on JCengines,

the distributor.

Remove the camshaft as follows:

3. Remove crankshaft gear retaining washer by

removing lock ring on crankshaft.

4.

Lay engine on its side to avoid dropping tappets

and remove camshaft assembly

as

a group.

If

necessary, pry it out with a screwdriver between

camshaft gear and crankcase.

CAUT,ON

Be sure the camshaft lobes

do

not

catch

5.

Remove tappets from camshaft end of pushrod

If

a lobe is slightly scored, dress it smooth with

a

fine

stone. If the camshaft is badly worn or scored, replace

it.

EZ.z-2

on

pushrod tappets during removal.

holes.'

The camshaft gear is a press fit on the camshaft and

drives

it

at one half crankshaft speed. The gear drives

the ignition timing (start-disconnect switch on four

cylinder) gear on two cylinder models. To remove;

use a hollow tool or pipe that will fit inside the gear

hore and over the center pin. Press the camshaft out

of the gear bore. Be careful not to damage the center

pin.

The camshaft bearings should be replaced

if

the

clearance to the camshaft is greater than specified: or

if the bearings show cracks, breaks, burrs, excessive

wear or other defects.

The camshaft to bearing clearance should be .0012"

to

.0037".

To check the rear bearing, remove the

expansion plug at the rear of the crankcase.

Press new bearings into place (Figure 81) using

bearing driving tool. Press the rear bearing flush with

the bottom of expansion plug recess. Press the front

bearing

in

flush with the crankcase front surface

so

the crankcase and bearing oil passages align. After

the rear bearing is installed, insert a new expansion

plug in the recess, using sealing compound, and

expand

it

into place with sharp blows at its center. The

bearings are a precision-type and do not require

reaming. Install the camshaft assembly as follows:

1.

Install key and press camshaft gear

on

its shaft,

2. Slide thrust washer onto shaft.

3. Lay engine on side or end and insert pushrod

tappets.

4.

Install camshaft assembly in engine. Align timing

marks on camshaft gear and crankshaft gear

(Figure 83).

5.

Replace pushrods and fuel pump. Install and.

retime distributor (JC only).

Figure 82. Mount governor components.

.

'*

Remove

rocker

cham be rs.

2.

Remove fuel

pump from the engine. Remove

distributor

(JC

onlv).

and pushrods

from

Crankshaft: The engines

use a counterbalanced,

ductile crankshaft. The two-cylinder crankshafts ride

on two lead-bronze bearings, the front one housed in

the crankcase and the rear-0Qe-h tbe bearing plate.

62

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...