PRESSURECAP

The

pressure

cap

increases

the boiling point

of

the

coolant

by

allowing

pressure

to

build

up in

the

cool-

ing system. The increase in boiling point reduces the

chances for coolant loss due to boil over.

A

15

psi

(103.5

kPa) pressurecap

will

raisethe boiling pointof

water to

250°F

(122OC) and the boiling point of a

50/50

mixture

of

water and antifreeze to 265°F

(132OC).

Inspect the pressure cap periodically for freedom of

operation and verify that the spring applies a fairly

stiff tension and is not easily compressed. Peel the

pressure cap gasket back and check for wear and

cracking. Excessive dripping from the overflow tube

may indicate a faulty cap. Replace the cap if

it

mal-

functions or is worn.

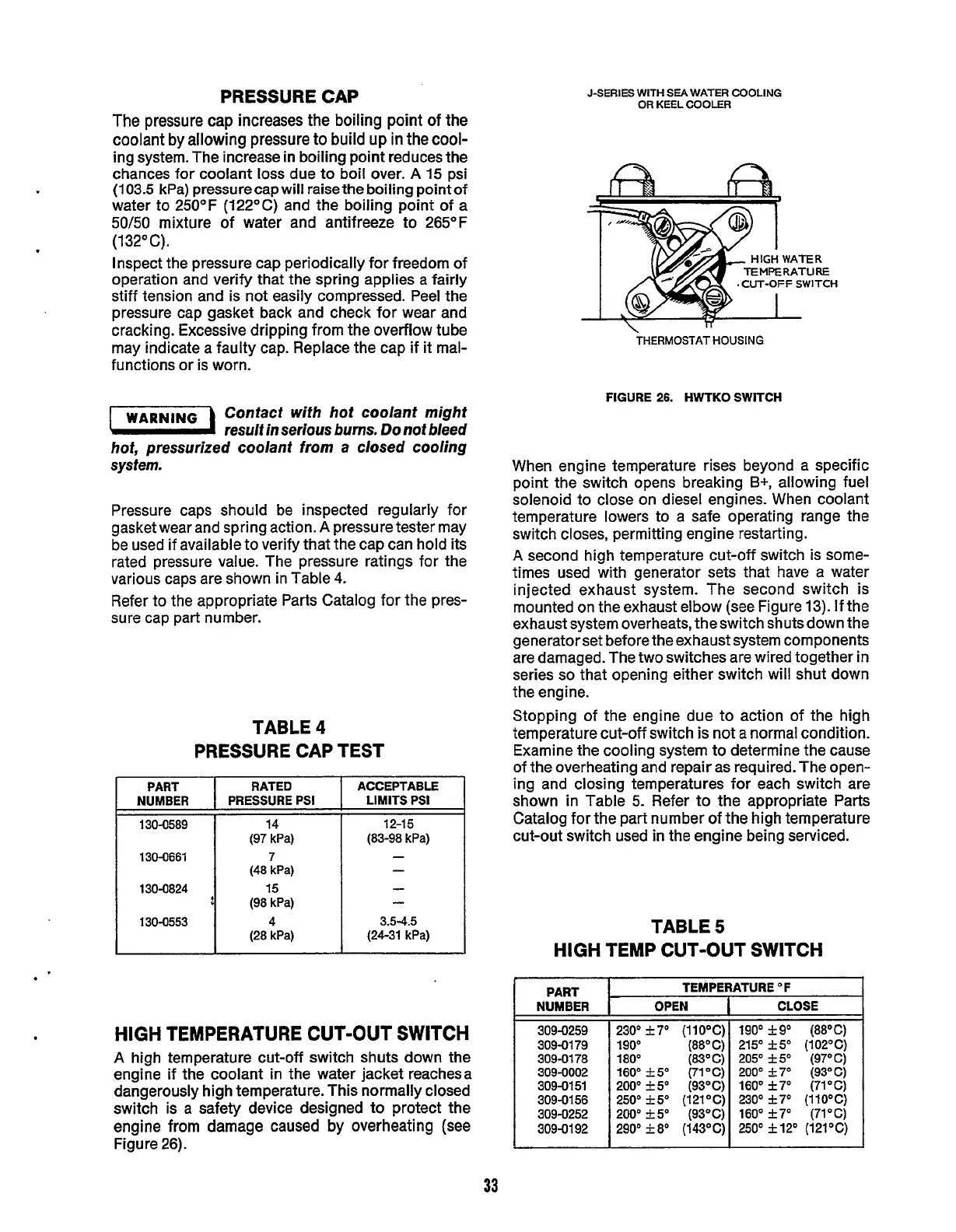

PART RATED

NUMBER PRESSURE PSI

130-0589 14

130-0661

7

130-0824

15

130-0553 4

(97 kPa)

(48 kPa)

1

(98 kPa)

(28 kPa)

JSERlES

WITH

SEA

WATER

COOLING

OR

KEEL

COOLER

ACCEPTABLE

LIMITS

PSI

(83-98 kPa)

1

2-1

5

-

-

-

-

3.5-4.5

(24-31 kPa)

Contact with hot coolant might

result in serious

bums.

Do

not bleed

hot, pressurized coolant from a closed cooling

system.

PART

NUMBER

309-0259

309-0179

309-0178

309-0002

309-0151

309-0156

309-0192

309-0252

Pressure caps should be inspected regularly for

gasketwear and spring action.

A

pressure tester may

be used if available to verify that the cap can hold its

rated pressure value. The pressure ratings for

the

various caps are shown in Table

4.

Refer to the appropriate Parts Catalog for the pres-

sure cap part number.

TEMPERATURE

OF

OPEN

CLOSE

230'

f7"

(110°C) 190' f9'

(88°C)

190' (88OC)

215"

f5"

(102OC)

180"

(83°C) 205"

25"

(97°C)

160"

f5"

(71'C)

200" -1-7' (93°C)

200'

25'

(93°C)

160" 57' (71°C)

250'

f5'

(121°C)

230' -1-7" (110°C)

290" 18" (143°C)

250"

f12" (121°C)

200'

f5"

(93'C)

160"

f7' (71°C)

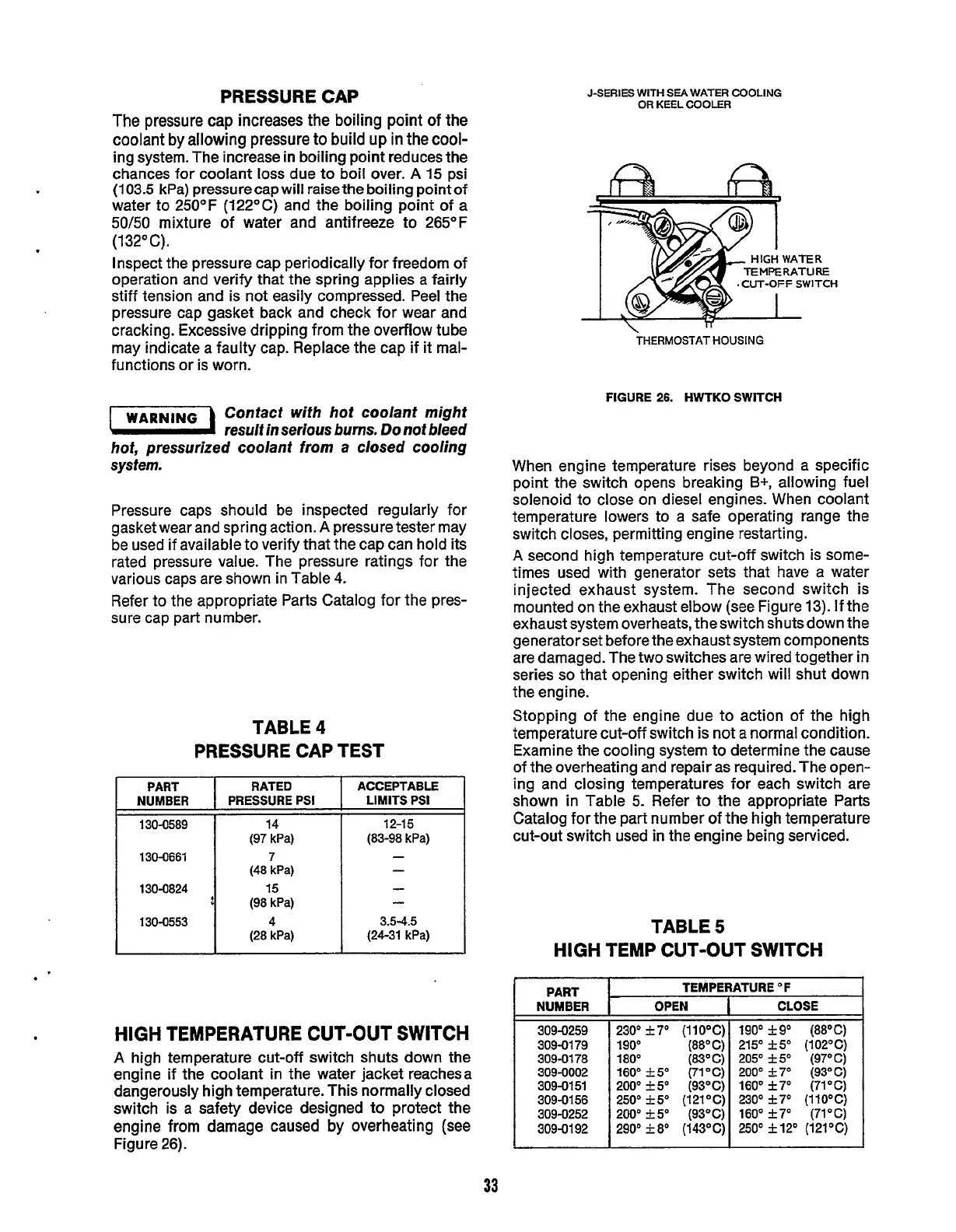

HIGH

TEMPERATURE CUT-OUT

SWITCH

A

high temperature cut-off switch shuts down the

engine if the coolant in the water jacket reachesa

dangerously high temperature. This normally closed

switch is

a

safety device designed

to

protect the

engine from damage caused

by

overheating (see

Figure

26).

UT-OFF

SWITCH

THERMOSTAT

HOUSING

FIGURE

26.

HWTKO

SWITCH

When

engine

temperature rises beyond a specific

point the switch opens breaking

B+,

allowing fuel

solenoid to close on diesel engines. When coolant

temperature lowers to a safe operating range the

switch closes, permitting engine restarting.

A

second high temperature cut-off switch is some-

times used with generator sets that have a water

injected exhaust system. The second switch

is

mounted on the exhaust elbow (see Figure

13).

If the

exhaust system overheats, theswitch shutsdown the

generator set before the exhaust system components

are damaged. The two switches are wired together in

series

so

that opening either switch will shut down

the engine.

Stopping of the engine due to action of the high

temperature cut-off switch is not

a

normal condition.

Examine the cooling system to determine the cause

of the overheating and repair as required. The open-

ing and closing temperatures for each switch are

shown in Table

5.

Refer to the appropriate

Parts

Catalog for the part number

of

the high temperature

cut-out switch used

in

the engine being serviced.

TABLE

5

HIGH

TEMP

CUT-OUT SWITCH

33

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...