Assembly

1.

2.

3.

4.

5.

6.

7.

When installing a new diaphragm, soak it in fuel

before assembling. Insert diaphragm spring and

soaked diaphragm into pump body.

Insert link and rocker arm into body and hook it

over diaphragm pull rod. Align rocker arm with

rocker arm pin hole and drive in pin. The priming

lever must be in position shown in Figure30 when

installing rocker arm.

Compress rocker spring and install between the

body and rocker arm.

Assemble cover to body, with notch marks lined

up. Install screws but do not tighten.

Fuelleakageis a fireand expio-

n

sion hazard fhaf might cause

severe personal injury or death. Use care when

reassembling fuel pump. All parts must align per-

fecfly or pump will leak fuel.

Push rockerarm in onefull strokeand hold

in

this

position to flex diaphragm.

Tighten cover screws alternately and securely,

then release rocker arm.

Install pump on the engine and repeat pressure

test.

INJECTION NOZZLES

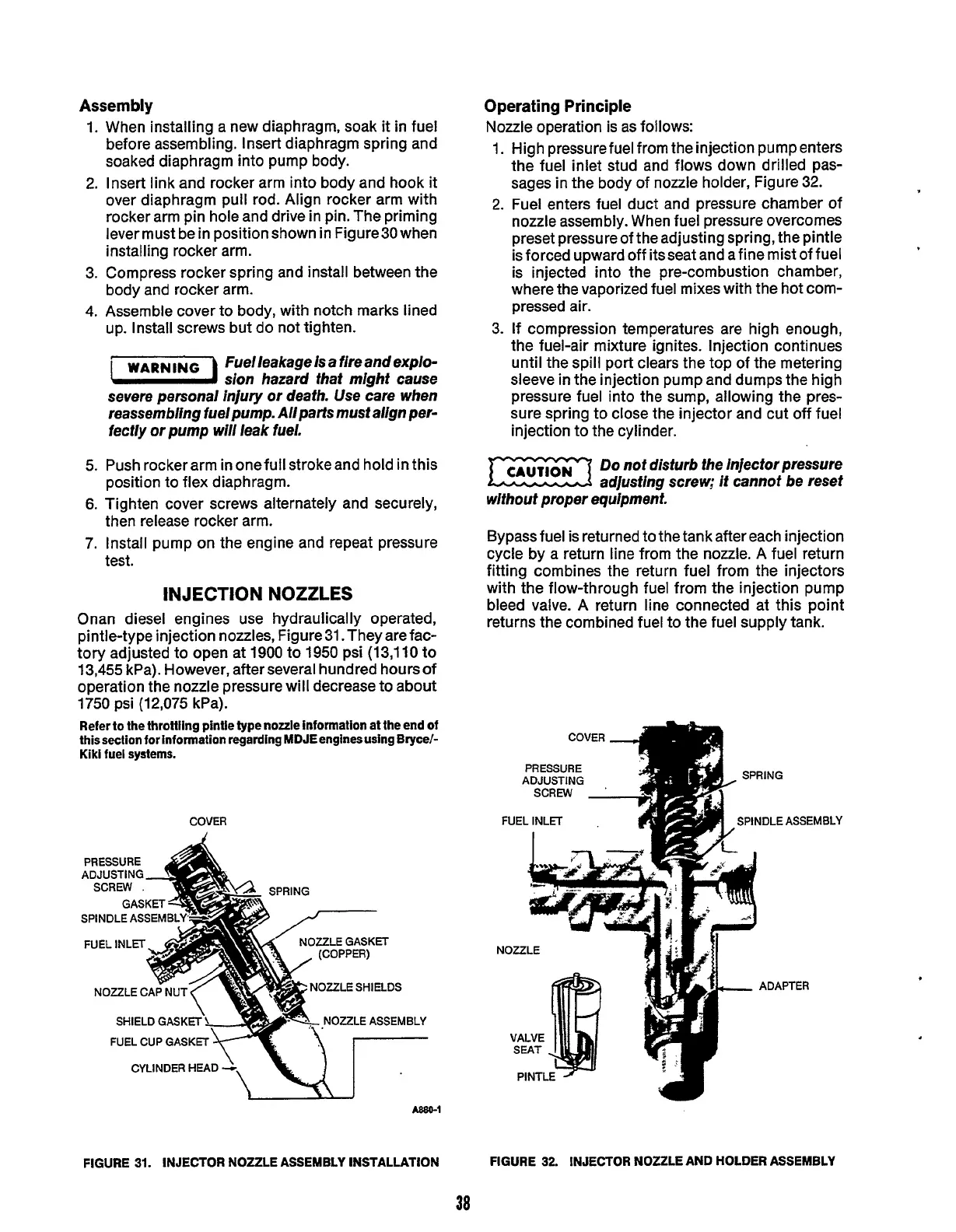

Onan diesel engines use hydraulically operated,

pintle-type injection nozzles, Figure 31. They are fac-

tory adjusted to open at 1900 to

1950

psi

(13,110

to

13,455

kPa). However, after several hundred hours of

operation the nozzle pressure will decrease to about

1750

psi

(1

2,075 kPa).

Refer to the throttling pintle type nozzle information at the end of

thissection for information regarding MDJEenginesusing Bryce/-

Kiki fuel systems.

COVER

PRESSURE

A&

GASKET

:

SPINDLE

ASSEMBLY

NOZZLE

CAP

NUT-(

7

SHIELD GASKET

f-

F

FUEL

CUP

GASKET

CYLINDER

HEAD

A,

7

\

Ul

A0aQ-j

FIGURE

31.

INJECTOR NOZZLE ASSEMBLY INSTALLATION

Operating Principle

Nozzle operation

is

as follows:

1.

2.

3.

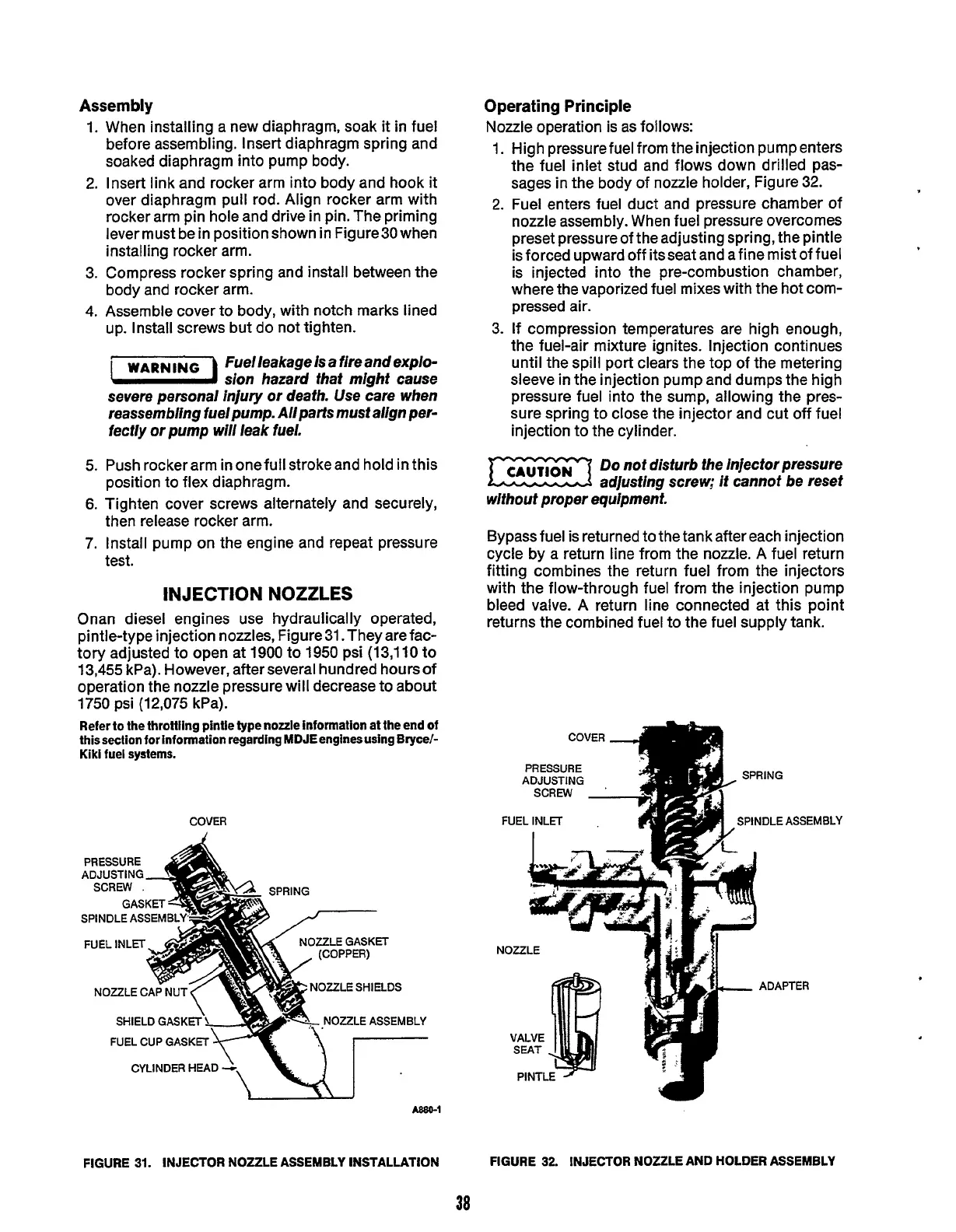

High pressure fuel from the injection pump enters

the fuel inlet stud and flows down drilled pas-

sages in the body of nozzle holder, Figure 32.

Fuel enters fuel duct and pressure chamber of

nozzle assembly. When fuel pressure overcomes

preset pressure of the adjusting spring, the pintle

is forced upward off its seat and a fine mist of fuel

is injected into the pre-combustion chamber,

where

the

vaporized fuel mixes with the hot com-

pressed air.

If compression temperatures are high enough,

the fuel-air mixture ignites. Injection continues

until the spill port clears the top of the metering

sleeve in the injection pump and dumps the high

pressure fuel into

the

sump, allowing the pres-

sure spring to close the injector and cut off fuel

injection to the cylinder.

Do

not disfurb fhe injector pressure

adjusfing screw;

it

cannof be reset

without proper equipment.

Bypass fuel is returned to the tank after each injection

cycle by a return line from the nozzle. A fuel return

fitting combines the return fuel from the injectors

with the flow-through fuel from the injection pump

bleed valve. A return line connected at this point

returns the combined fuel to the fuel supply tank.

.

FIGURE

32.

INJECTOR NOZZLE AND HOLDER ASSEMBLY

38

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...