BRYCE/KIKI

FUEL

SYSTEM

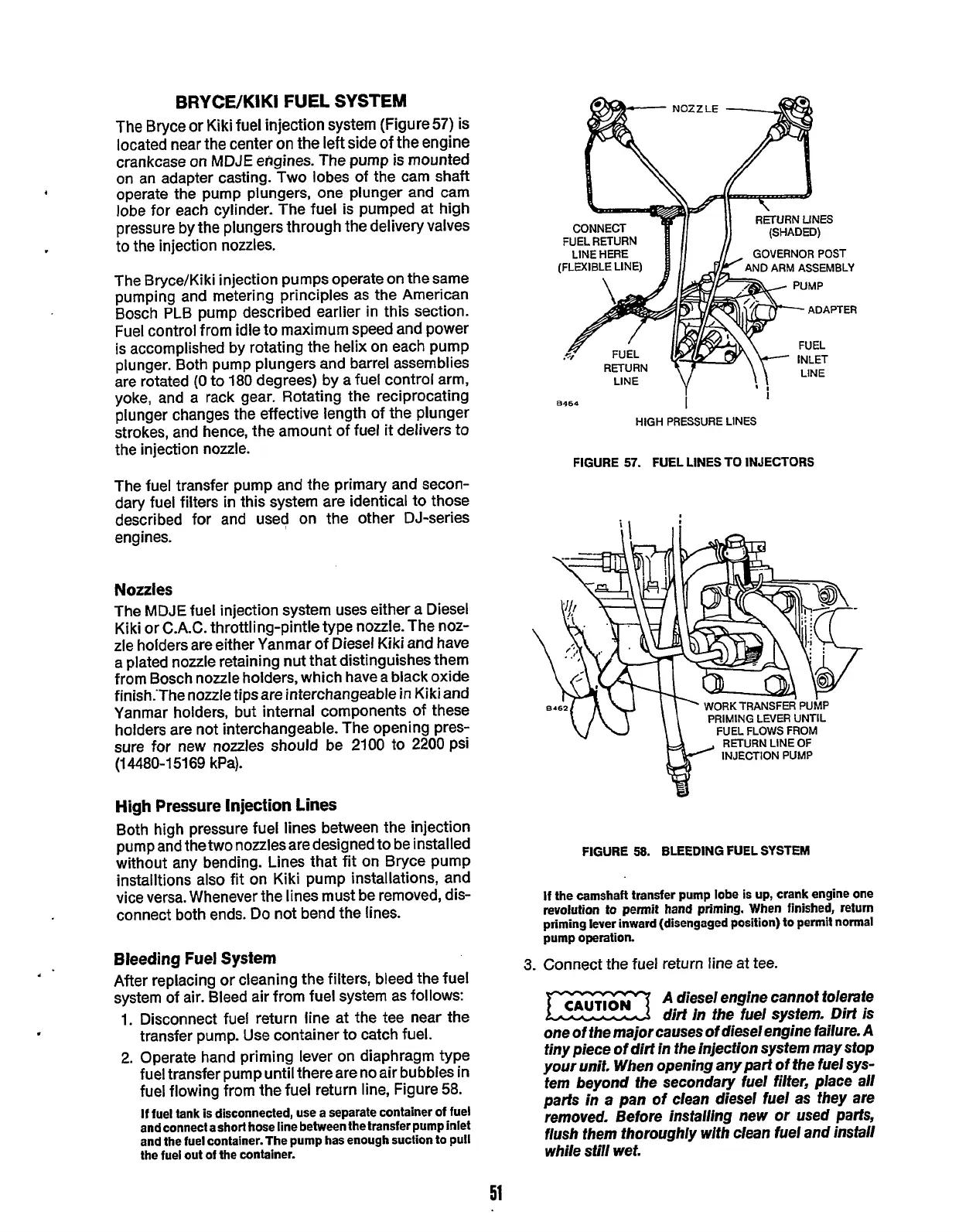

The Bryce or

Kiki

fuel injection system (Figure57) is

located near the center on the left side of the engine

crankcase on

MDJE

engines. The pump is mounted

on an adapter casting. Two lobes of the cam shaft

operate the pump plungers, one plunger and cam

lobe for each cylinder. The fuel is pumped at high

pressure by

the

plungers through the delivery valves

The Bryce/Kiki injection pumps operate on the same

pumping and metering principles as the American

Bosch PLB pump described earlier in this section.

Fuel control from idle to maximum speed and power

is accomplished by rotating

the

helix on each pump

plunger. Both pump plungers and barrel assemblies

are rotated

(0

to 180 degrees) by a fuel control arm,

yoke, and a rack gear. Rotating the reciprocating

plunger changes the effective length of the plunger

strokes, and hence, the amount of fuel

it

delivers to

the injection nozzle.

The fuel transfer pump and

the

primary and secon-

dary fuel filters in this system are identical to those

described for and used on the other DJ-series

engines.

4

to the injection nozzles.

FUEL RETURN

(FLEXIBLE LINE)

GOVERNOR

POST

ARM ASSEMBLY

HIGH

PRESSURE LINES

FIGURE

57.

FUEL LINES

TO

INJECTORS

Nozzles

The

MDJE

fuel injection system uses either a Diesel

Kiki or

C.A.C.

throttling-pintle type nozzle. The noz-

zle

holders are either Yanmar of Diesel Kiki and have

a plated nozzle retaining nut that distinguishes them

from Bosch nozzle holders, which have a black oxide

finish.The nozzle tipsare interchangeable in Kiki and

Yanmar holders, but internal components of these

holders are not interchangeable. The opening pres-

sure for new nozzles should be

2100

to 2200 psi

(14480-15169 kPa).

High Pressure Injection Lines

Both high pressure fuel lines between the injection

pump and the two nozzles are designed to be installed

without any bending. Lines that fit on Bryce pump

installtions also fit on Kiki pump installations, and

vice versa. Whenever the lines must be removed, dis-

connect both ends. Do not bend the lines.

Bleeding Fuel

System

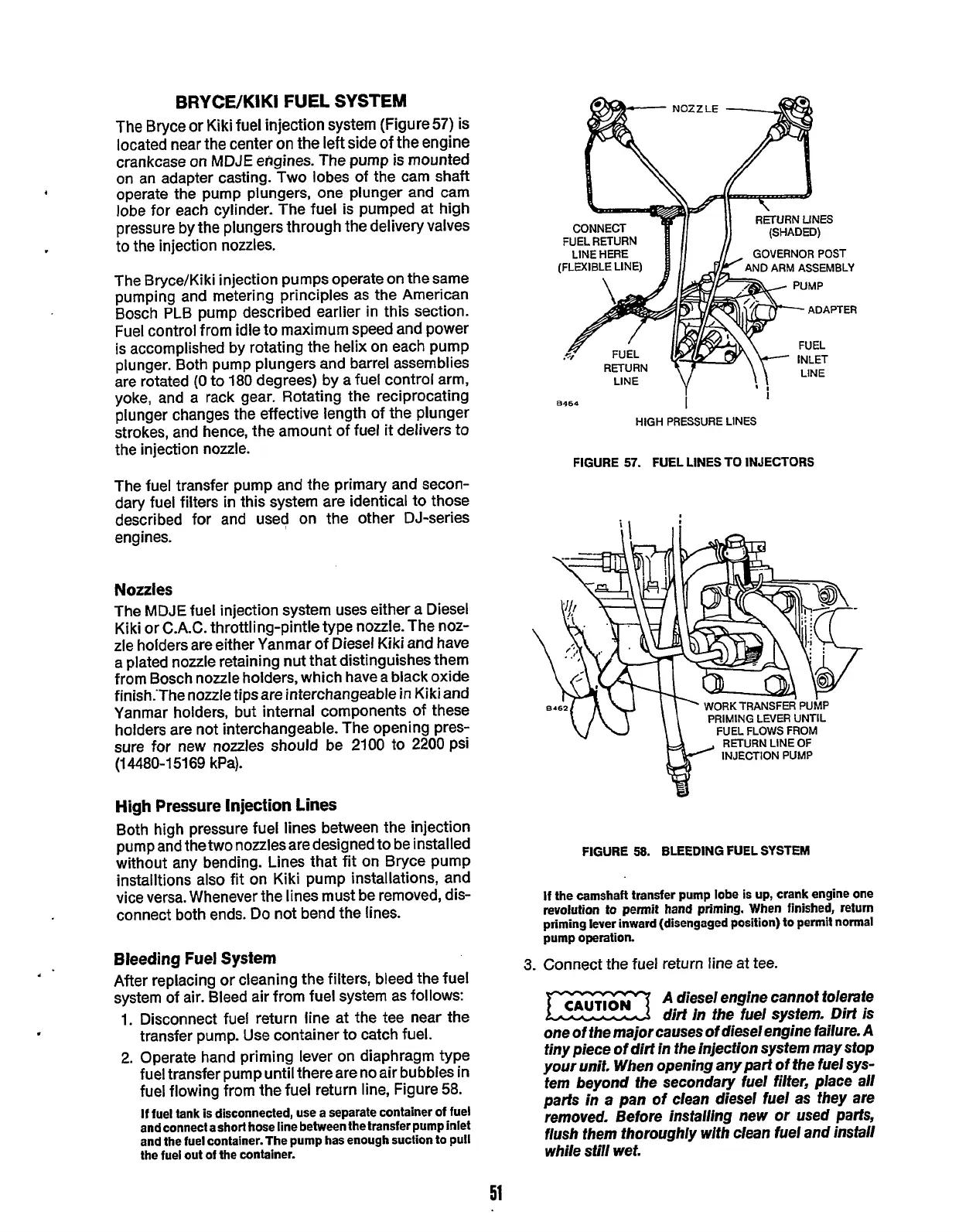

After replacing or cleaning the filters, bleed the fuel

system of air. Bleed air from fuel system as follows:

1.

Disconnect fuel return line at the tee near the

transfer pump. Use container to catch fuel.

2.

Operate hand priming lever on diaphragm type

fuel transfer pump until there are no air bubbles in

fuel flowing from the fuel return

line,

Figure

58.

If

fuel tank is disconnected, use

a

separate container

of

fuel

and connect

a

short hose line between the transfer pump inlet

and the fuel container. The pump has enough suction to pull

the fuel out

of

the container.

PRIMING

LEVER UNTIL

FUEL FLOWS FROM

RETURN LINE OF

INJECTION PUMP

FIGURE

58.

BLEEDING FUEL

SYSTEM

If

the camshaft transfer pump lobe

is

up,

crank engine one

revolution

to

permit hand priming. When finished, return

priming lever inward (disengaged position)

to

permit normal

pump operation.

3.

Connect the fuel return line at tee.

A

diesel engine cannot tolerate

dirt In the fuel system.

Dirt

is

one

of

the major causes

of

diesel engine failure.

A

tiny piece

of

dirt

in

the injection system may

stop

your unit. When opening any part

of

the fuel sys-

tem beyond the secondary fuel filter, place

all

parts

in

a

pan

of

clean diesel fuel as they are

removed. Before insfalling new

or

used

parfs,

flush

them thoroughly with clean fuel and

insfall

while

still

wet.

51

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...