BRYCE/KIKI FUEL INJECTION PUMPS

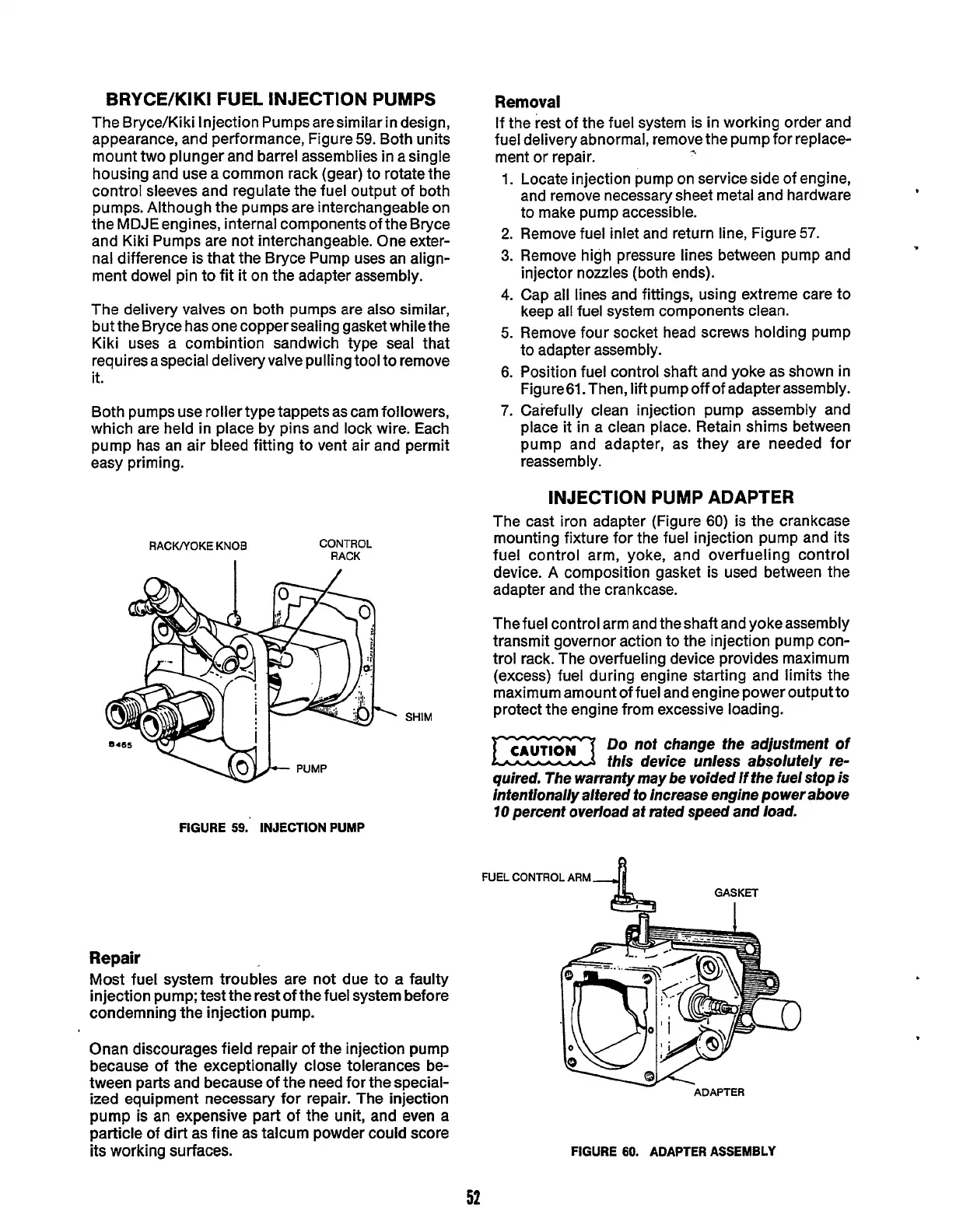

The Bryce/Kiki Injection Pumps aresimilar in design,

appearance, and performance, Figure

59.

Both units

mount two plunger and barrel assemblies in asingle

housing and use a common rack (gear) to rotate the

control sleeves and regulate the fuel output of both

pumps. Although the pumps are interchangeable on

the

MDJE

engines, internal components of the Bryce

and Kiki Pumps are not interchangeable. One exter-

nal difference is that the Bryce Pump uses an align-

ment dowel pin to fit

it

on the adapter assembly.

The delivery valves on both pumps are also similar,

but the Bryce has one copper sealing gasket whilethe

Kiki uses a combintion sandwich type seal that

requires a special deliveryvalve pulling tool to remove

it.

Both pumps use roller type tappets as cam followers,

which are held

in

place by pins and lock wire. Each

pump has an air bleed fitting to vent air and permit

easy priming.

RACKNOKE

KNOB

CONTROL

RACK

I

SHIM

Removal

If the rest of the fuel system is in working order and

fuel deliveryabnormal, remove the pump for replace-

ment

or

repair.

*

1.

2.

3.

4.

5.

6.

7.

Locate injection pump on service side of engine,

and remove necessary sheet metal and hardware

to make pump accessible.

Remove fuel inlet and return line, Figure

57.

Remove high pressure lines between pump and

injector nozzles (both ends).

Cap all lines and fittings, using extreme care to

keep all fuel system components clean.

Remove four socket head screws holding pump

to adapter assembly.

Position fuel control shaft and yoke as shown in

Figure61. Then, lift pump off of adapter assembly.

Carefully clean injection pump assembly and

place

it

in a clean place. Retain shims between

pump and adapter, as they are needed for

reassem b

I

y.

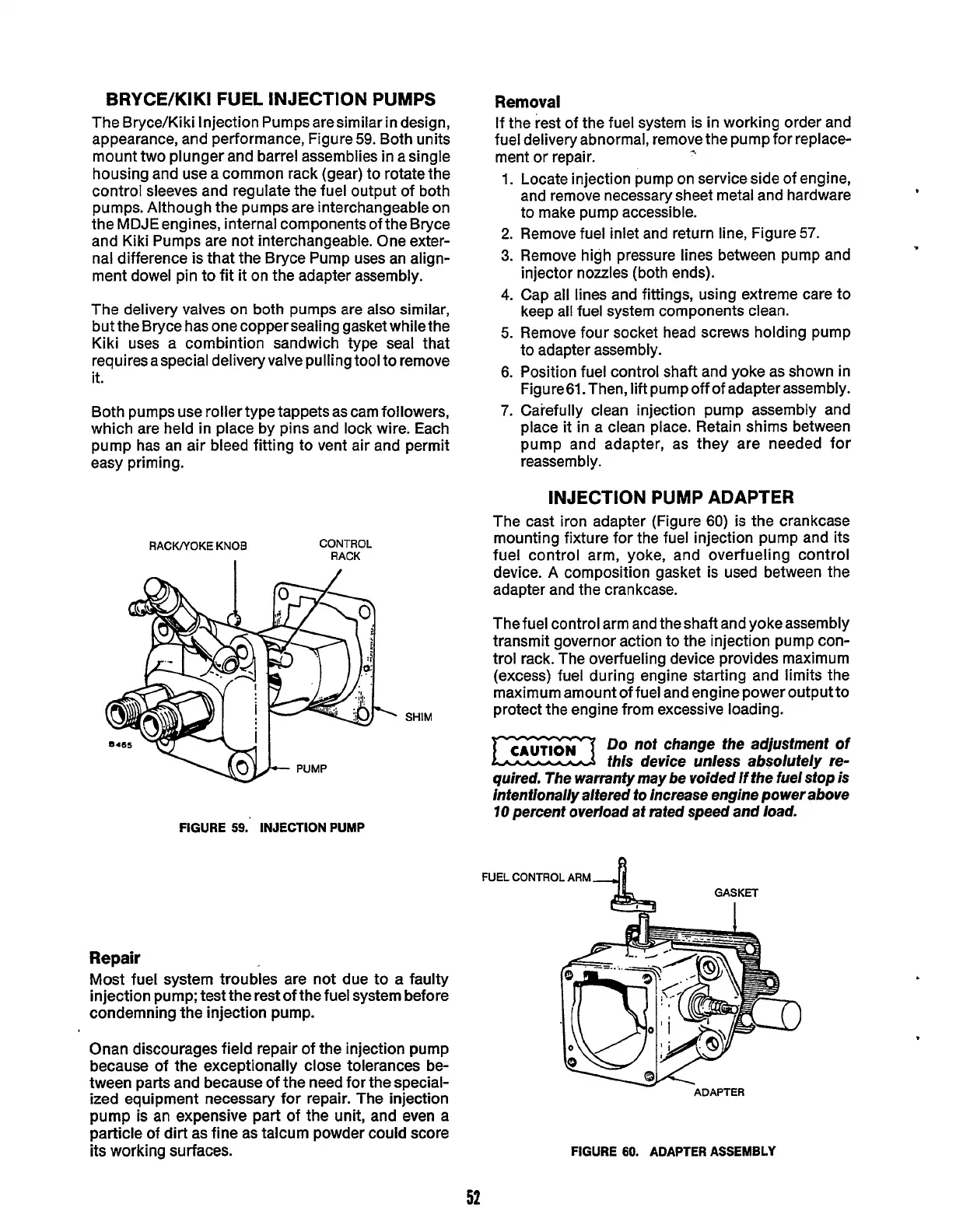

INJECTION PUMP ADAPTER

The cast iron adapter (Figure

60)

is

the

crankcase

mounting fixture for the fuel injection pump and its

fuel control arm, yoke, and overfueling control

device.

A

composition gasket is used between the

adapter and the crankcase.

Thefuel control arm and theshaft and yokeassembly

transmit governor action to the injection pump con-

trol rack. The overfueling device provides maximum

(excess) fuel during engine starting and limits the

maximum amount of fuel and engine power output to

protect the engine from excessive loading.

Do

nof change the adjusfmenf of

Ezx

this device unless absolutely re-

quired. The warranty may be voided if the fuel stop

is

infenfionally altered to increase engine power above

70

percenf overload af rafed speed and load.

CAUT,ON

FIGURE

59.

INJECTION PUMP

FUEL

CONTROL

ARM

GASKET

I

Repair

Most fuel system troubles are not due to a faulty

injection pump; test the rest of the fuel system before

condemning the injection pump.

Onan discourages field repair of the injection pump

because of the exceptionally close tolerances be-

tween parts and because of the need for the special-

ized equipment necessary for repair. The injection

pump is an expensive part of

the

unit, and even a

particle of dirt as fine as talcum powder could score

its working surfaces.

-

ADAPTER

FIGURE

60.

ADAPTER ASSEMBLY

52

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...