t

and

over

the cooling fins

and surfaces

of the eneine.

Heated

air

is expelled

through

a single

discharge

and

away from

the

unit and

installatton

area.

LOCATION

The

compartment

itself should

be of vapor

tight

design

and

completely

independent

of living quarters.

The

interior

Iining should

be fireproof.

A

sheet

metal cover-

ed

compartment

may be readily

sealed

and

lends

itself

easily

to

treatment.

The set

may

have to

be removed

fot service,

so

nrake the door

large

enough

to facilitate

removal

of the

unit,

The

compartment

location

is

determined

by

physical

size,

access

opening and

most

importalt,

best mounting

support.

Allow

2" clearance

on

a1l

sides

of the

unit

for

rocking

on

mounts.

POSITIONING

The following

should

be

considered for

accessibility

when

mounting

the unit

in a compartment.

(Position

so

operating

instructions

and

nameplate are

visible

and/or

install

an accessible

nameplate. data

decal

or sticker.

)

I.

Make

air

discharge

duct as short

as

possible.

Position so exhaust

heated air is

flot

drawn

into

cool air

inlet.

2, Air

cleaner should

be easy to lemove

and service.

3.

Battery

or

batteries

must

be accessible for service.

4.

Oil

fill

tube cap should

be easy to

reach.

5.

The

control

box switch should

be

visible.

6. Provide space for

muffler.

7.

Oi1

drain should

be readily accessible.

8.

Cylindet

head should

be readily accessible

for

servtce.

9. Rope stait

sheave should

be accessible.

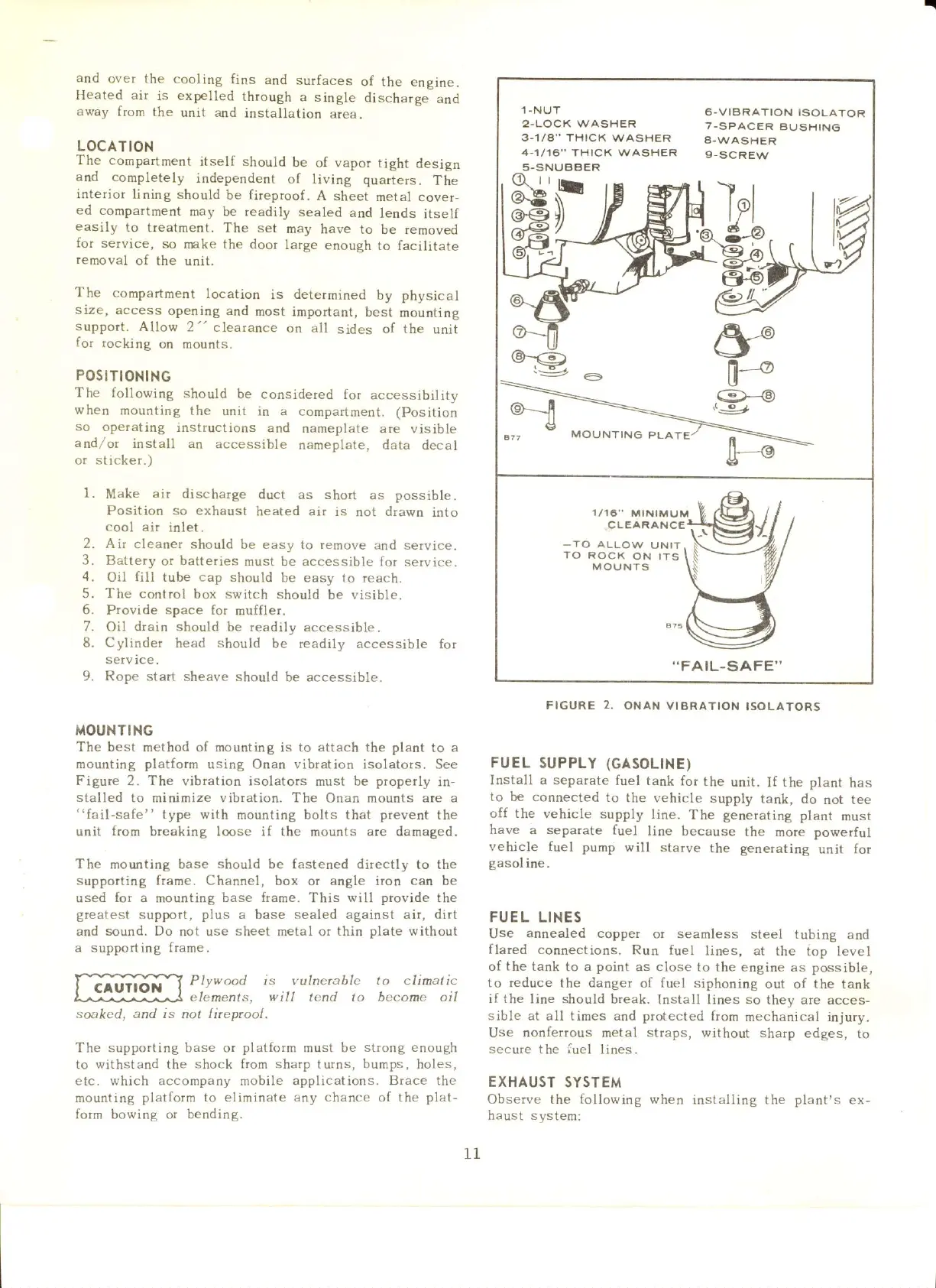

MOUNTING

The best method of mounting

is

to attach the plant

to a

.nounting

platfotm

using Onan vibration isolators. See

Figure 2. The

vibration isolators must be

propetly

in-

stalled

to minirnize vibtation. The

Onan mou[ts

are a

"fail-safe"

type with

mounting bolts that

prevent

the

unit

from

breaking loose if the

mounts

are damaged.

The

mounting base

should be

fastened directly to the

supporting ftame. Channel,

box or angle iron

can

be

used

for

a mounting base

ftame.

This will

provide

the

greatest

support,

plus

a base sealed against air, dirt

and

sound. Do

not use

sheet

metal or

thin

Dlate

without

a supporting frame.

Plywood is vulnetable to climatic

elerrenls,

will

tend to become oil

s<>aked, and is

not

[ireprool.

The supporting base or

platform

must be

strong enough

to withstand the shock from

sharp

turns, bumps, holes,

etc. which accompany mobile applications. Brace the

mounting

platform to eliminate any chance of the

plat-

form bowing or bendin

g.

FIGURE

2.

ONAN VIERATION

ISOLATORS

FUEL

SUPPLY

(GASOLINE)

Install a separate

fuel tank

for the

unit.

If

the plant

has

to be connected

to

the vehicle

supply

tank, do

not

tee

off the

vehicle supply

line.

The

generatiflg

plant

rnust

have a separate

fuel

line

because

the more powerful

vehicle

fuel pump

will starve

the generating

unit for

gasoline.

FUEL LINES

Use

annealed copper

ot seamless steel

tubing and

flated

connections.

Run fuel

lines, at the

top level

of the tank

to a

point

as close

to the engine as possible,

to reduce the danger

oI

fuel

siphoning

out of the tank

if the

line

should

break.

Install lines

so

they are

acces-

sible at all times ard protected from

mechanical injury.

Use nonferrous metal

sttaps,

without sharp

edges,

to

secure

the

fuel

lines.

EXHAUST

SYSTEM

Observe the

following

when

installing the

plant's

ex-

haust system:

6.VIBRATION ISOLATOR

7-SPACER

BUSHING

A-v\/ASHER

9-SCREW

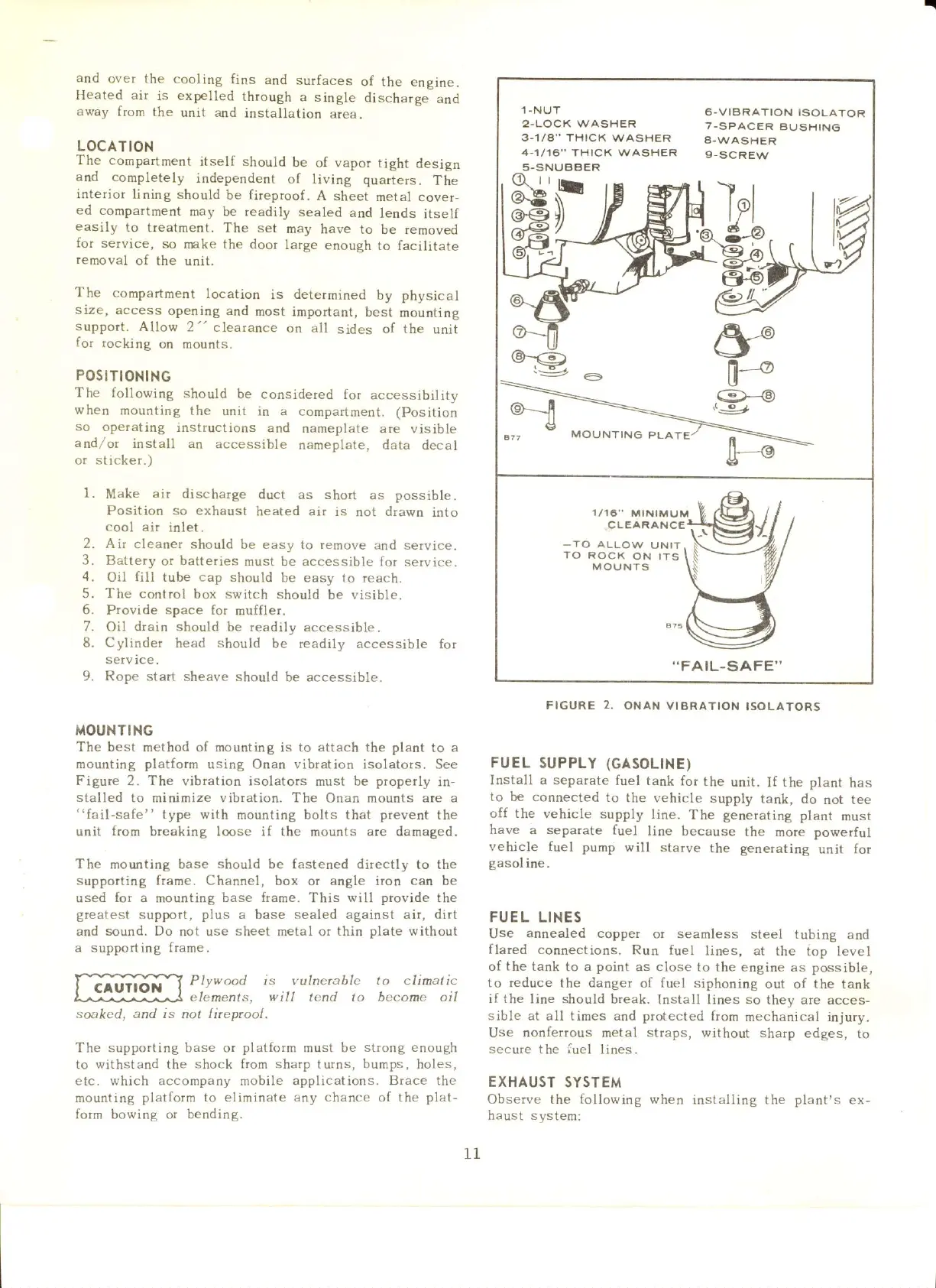

_TO

ALLOW

U NIT

TO

ROCK

ON ITS

MOUNTS

..FAIL-SAFE''

11

Loading...

Loading...