OPERATION

BEFORE

STARTING

Be sure the generating set is properly filled with oil

and

fuel.

Crankcase Oil: Fill the crankcase with oil to the FULL

mark on the oil level indicator. Do not overfill! Oil

capacity is 4 quarts (4-1/2 quarts with filter). Use a

good quality oil with the API (American Petroleum

Institute) designation SE orSE/CC. Do not use an oil

with the designation CD unless it is also designated

SE and the oil manufacturer certifies it will perform

satisfactorily in gasoline engines. Use the following

as a guide for the proper oil according to temperature

ranges:

BREAK-IN

PROCEDURE

Break in a new or reconditioned unit using the

recommended oil and following this sequence:

1.

One-half hour at half-load

2.

One half hour at three-quarter load

3. Full

load.

This method of breaking in the unit speeds piston ring

seating.

Continuous running at half (light)'load forthe

first few hundred hours usually results in poor piston

ring seating, causing higher than normal oil

con-

sumption and blowby.

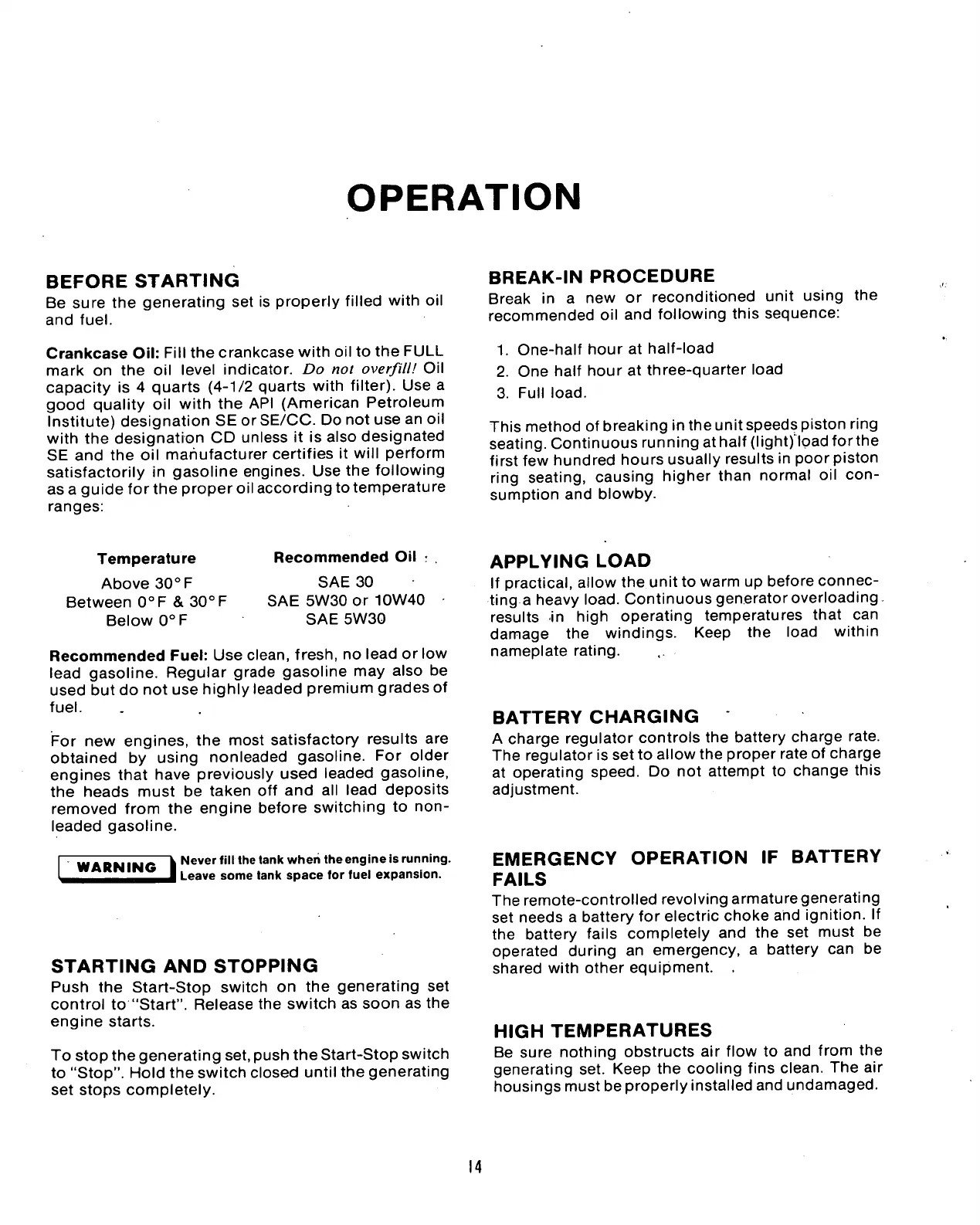

Temperature

Above 30° F

Between 0

o

F & 30° F

Below 0

o

F

Recommended Oil :

SAE 30

SAE 5W30 or 10W40

SAE 5W30

Recommended Fuel: Use clean, fresh, no lead or low

lead gasoline. Regular grade gasoline may also be

used but do not use highly leaded premium grades of

fuel.

For new engines, the most satisfactory results are

obtained by using nonleaded gasoline. For older

engines that have previously used leaded gasoline,

the heads must be taken off and all lead deposits

removed from the engine before switching to non-

leaded gasoline.

WARNING

"k Never fill the tank when the engine is running.

J Leave some tank space for fuel expansion.

STARTING

AND

STOPPING

Push the Start-Stop switch on the generating set

control to "Start". Release the switch as soon as the

engine starts.

To stop the generating set, push the Start-Stop switch

to "Stop". Hold the switch closed until the generating

set stops completely.

APPLYING

LOAD

If practical, allow the unit to warm up before connec-

ting a heavy

load.

Continuous generator overloading,

results in high operating temperatures that can

damage the windings. Keep the load within

nameplate rating.

BATTERY

CHARGING

A charge regulator controls the battery charge rate.

The regulator is set to allow the proper rate of charge

at operating speed. Do not attempt to change this

adjustment.

EMERGENCY

OPERATION

IF

BATTERY

FAILS

The remote-controlled revolving armature generating

set needs a battery for electric choke and ignition. If

the battery fails completely and the set must be

operated during an emergency, a battery can be

shared with other equipment. .

HIGH

TEMPERATURES

Be sure nothing obstructs air flow to and from the

generating set. Keep the cooling fins clean. The air

housings must be properly installed and undamaged.

14

Loading...

Loading...