MAINTENANCE

Regular scheduled maintenance lowers operating costs and lengthens the service life of the generating set. Use

the following guide to establish effective service periods. However, actual conditions under which the unit

operates is the determining factor in establishing a maintenance program. When operating the unit in very dusty or

dirty conditions, some of the service periods may have to be reduced. Check the condition of the crankcase oil, the

filters,

etc., frequently until proper service time intervals can be established.

For any.abnormalities in operation, unusual noises from the engine or accessories, loss of power, overheating,

etc., contact your nearest Onan dealer.

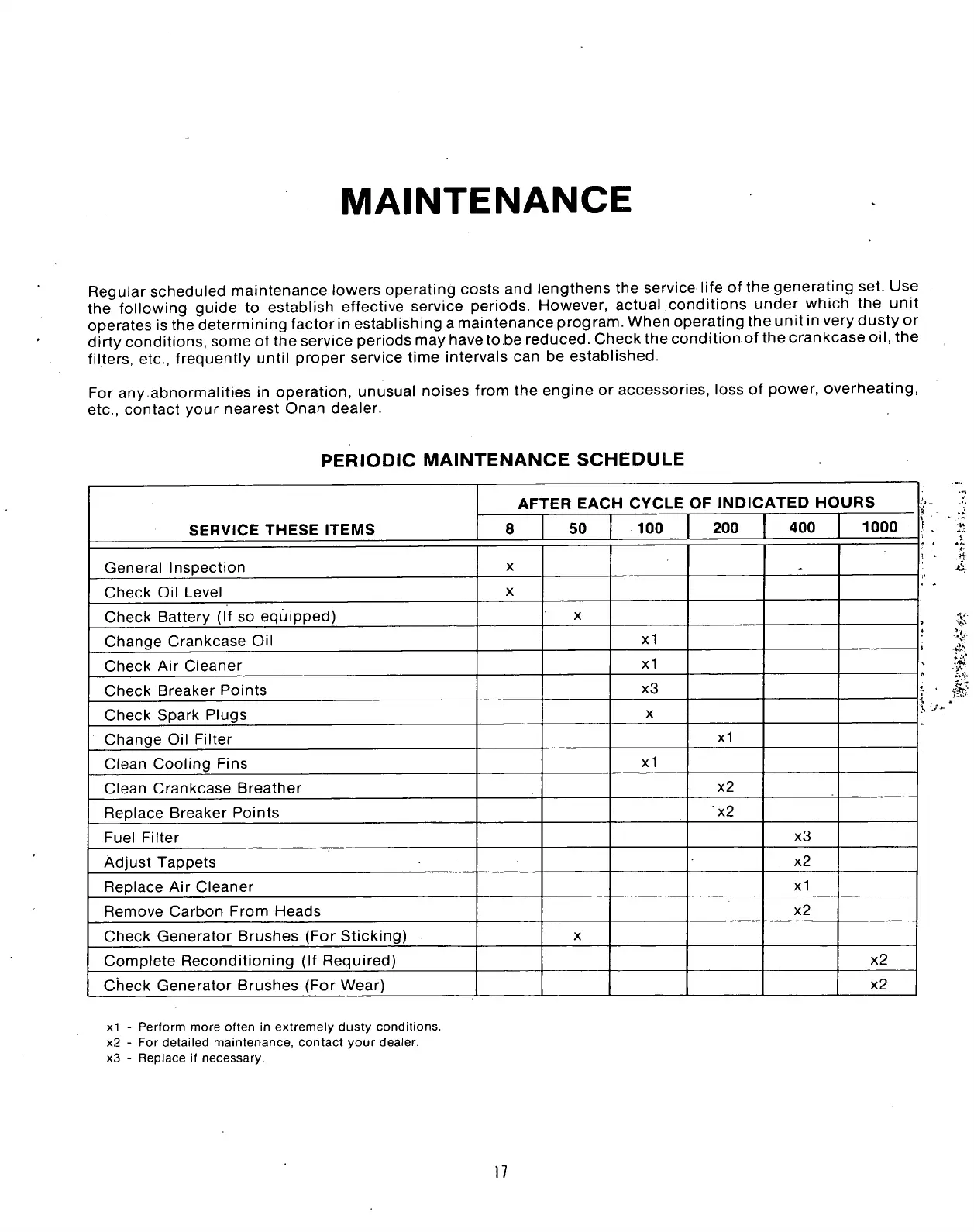

PERIODIC

MAINTENANCE

SCHEDULE

SERVICE THESE

ITEMS

AFTER EACH CYCLE

OF INDICATED

HOURS

SERVICE THESE

ITEMS

8

50

100

200 400

1000

General Inspection

X

Check Oil Level

X

Check Battery (If so equipped)

X

Change Crankcase Oil

x1

Check Air Cleaner

xl

Check Breaker Points

x3

Check Spark Plugs

X

Change Oil Filter

xl

Clean Cooling Fins

xl

Clean Crankcase Breather

x2

Replace Breaker Points

x2

Fuel Filter

x3

Adjust Tappets

x2

Replace Air Cleaner

xl

Remove Carbon From Heads

x2

Check Generator Brushes (For Sticking)

X

Complete Reconditioning (If Required)

x2

Check Generator Brushes (For Wear)

x2

•V-

xl - Perform more often in extremely dusty conditions.

x2 - For detailed maintenance, contact your dealer.

x3 - Replace if necessary.

17

Loading...

Loading...