OIL

LEVEL

Check theoil level daily oral least every eight hours of

operating time. Check more often on a new unit as oil

consumption is higher until the piston rings seat

properly.

OIL

CHANGE

Initial oil change should be made after the first 25

operating hours; change every 100 hours after that. If

operating in extremely dusty conditions or in cold

weather, change oil more frequently.

Oil capacity is 4 quarts, 4-1/2 quarts if replacing the

oil filter too. Do not mix brands orgradesof motoroil.

Use only a good quality oil with the designation

SE/CC (former designation was MS, MS/DG). If

necessary to add oil between changes, use the same

brand and grade of oil as is already present in the

crankcase.

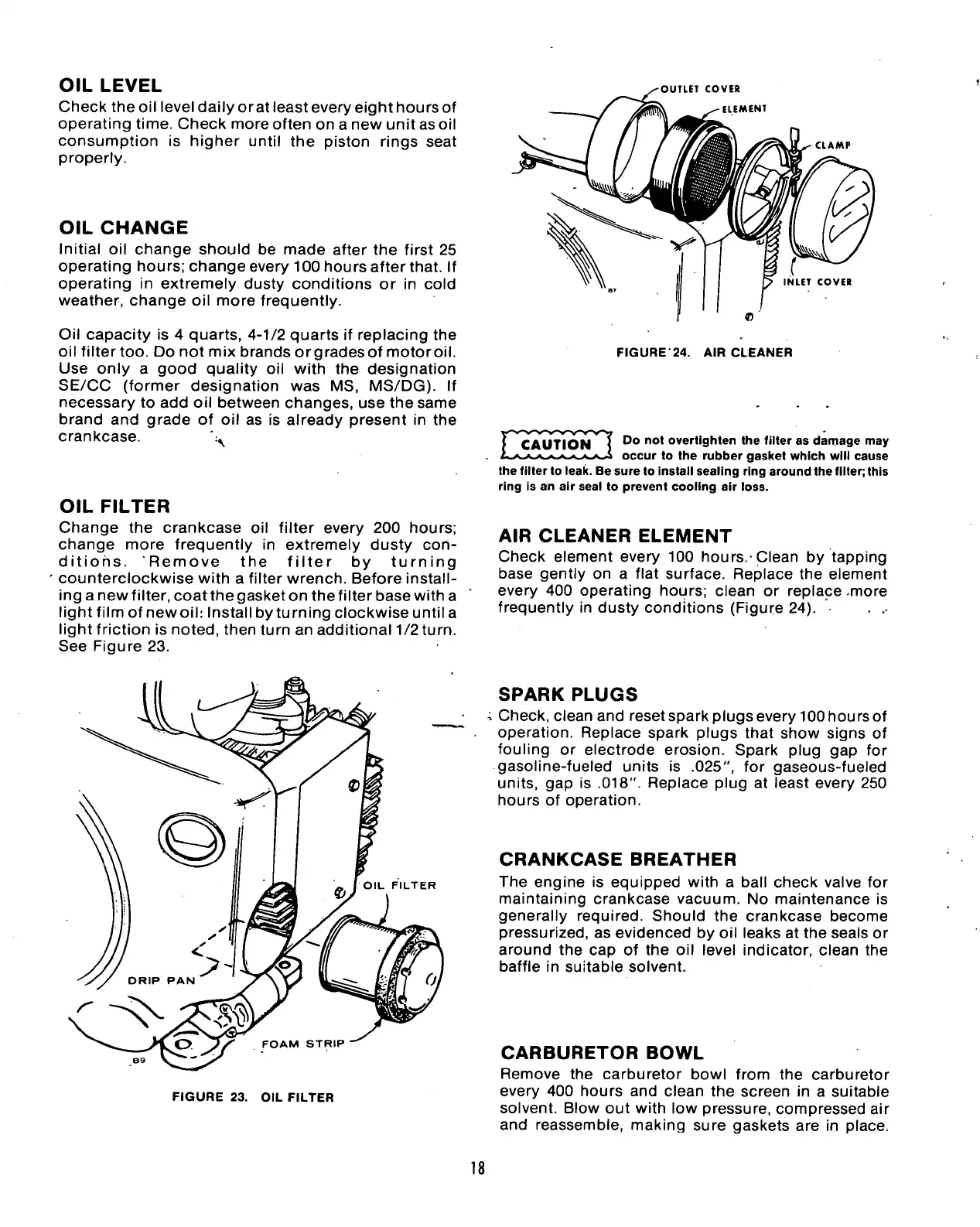

OIL FILTER

Change the crankcase oil filter every 200 hours;

change more frequently in extremely dusty

con-

ditions. Remove the filter by turning

counterclockwise with a filter wrench. Before install-

ing a new filter, coat the gasket on the filter base with a

light film of new

oil:

Install by turning clockwise until a

light friction is noted, then turn an additional 1/2

turn.

See Figure 23.

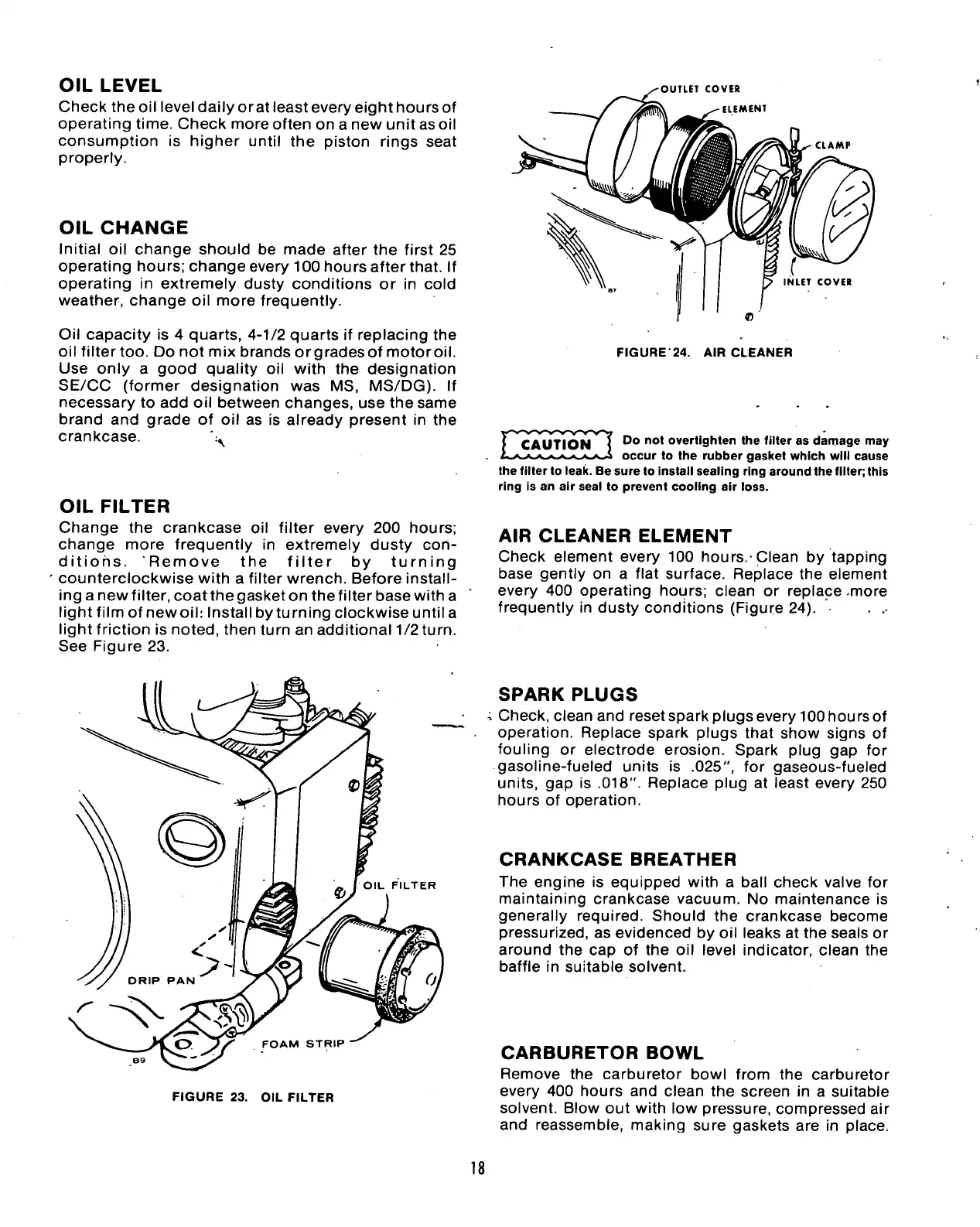

-OUTLET COVER

- ELEMENT

^ INLET COVER

FIGURE 24. AIR CLEANER

CAUTION

Oo not overtighten the filter as damage may

occur to the rubber gasket which will cause

the filter to leak. Be sure to install sealing ring around the filter; this

ring is an air seal to prevent cooling air loss.

AIR CLEANER

ELEMENT

Check element every 100 hours.-Clean by tapping

base gently on a flat surface. Replace the element

every 400 operating hours; clean or replace .more

frequently in dusty conditions (Figure 24). • . .-

FIGURE 23. OIL FILTER

SPARK PLUGS

Check, clean and reset spark plugs every lOOhours of

operation.

Replace spark plugs that show signs of

fouling or electrode erosion. Spark plug gap for

gasoline-fueled units is .025", for gaseous-fueled

units,

gap is .018". Replace plug at least every 250

hours of operation.

CRANKCASE BREATHER

The engine is equipped with a ball check valve for

maintaining crankcase vacuum. No maintenance is

generally required. Should the crankcase become

pressurized, as evidenced by oil leaks at the seals or

around the cap of the oil level indicator, clean the

baffle in suitable solvent.

CARBURETOR

BOWL

Remove the carburetor bowl from the carburetor

every 400 hours and clean the screen in a suitable

solvent. Blow out with low pressure, compressed air

and reassemble, making sure gaskets are in place.

18

Loading...

Loading...