warms up. Rough operation of a cold engine indicates

the need of a choke adjustment. See Figure 32.

Sisson Choke: Adjust the Sisson choke by loosening

the screw holding the choke wire and repositioning it

to obtain smooth cold engine performance.

Thermo-Magnetic Choke: Adjust the thermo-

magnetic choke by loosening the screw and rotating

the entire assembly to obtain smooth cold engine

operation.

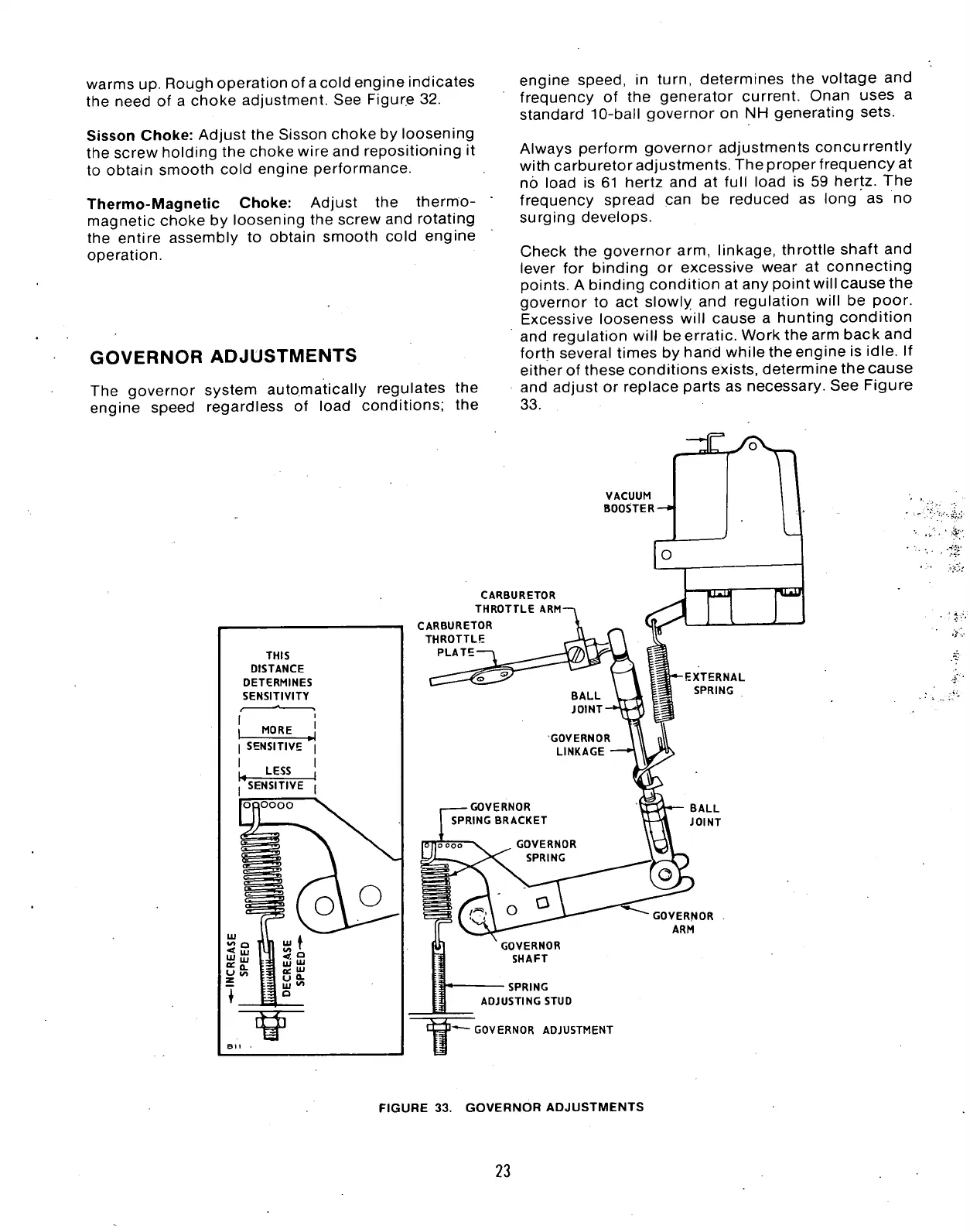

GOVERNOR

ADJUSTMENTS

The governor system automatically regulates the

engine speed regardless of load conditions; the

engine speed, in

turn,

determines the voltage and

frequency of the generator current. Onan uses a

standard 10-ball governor on NH generating sets.

Always perform governor adjustments concurrently

with carburetor adjustments. The proper frequency at

no load is 61 hertz and at full load is 59 hertz. The

frequency spread can be reduced as long as no

surging develops.

Check the governor arm, linkage, throttle shaft and

lever for binding or excessive wear at connecting

points. A binding condition at any point will cause the

governor to act slowly and regulation will be poor.

Excessive looseness will cause a hunting condition

and regulation will be erratic. Work the arm back and

forth several times by hand while the engine is idle. If

either of these conditions exists, determine the cause

and adjust or replace parts as necessary. See Figure

33.

VACUUM

BOOSTER-

THIS

DISTANCE

DETERMINES

SENSITIVITY

CARBURETOR

THROTTLE ARM-

CARBURETOR

THROTTLE

PLATE-

GOVERNOR

ARM

ADJUSTING STUD

GOVERNOR ADJUSTMENT

FIGURE 33. GOVERNOR ADJUSTMENTS

23

Loading...

Loading...