Linkage: The engine starts at wide open throttle.

Rotate the ball joint housing to adjust the length of the

linkage connecting the governor arm to the throttle

arm.

Adjust the length so that with the engine stopped

and the carburetor wide open, the ball joint housing is

even with the governor arm ball joint. This setting

allows immediate control by the governor after star-

ting and synchronizes travel of the governor arm and

the throttle shaft.

Speed Adjustment: The tension applied to the gover-

nor spring determines the speed at which the engine

operates: Increasing spring tension increases engine

speed;

decreasing tension decreases engine speed.

The no-load speed of the engine should be slightly

higher than the speed requirements of the connected

load.

For example: lf the connected load is to turn at 1800

rpm,

set the no-load speed of the engine at 1875 rpm.

Check the speed with a tachometer.

If the engine needs a speed adjustment, turn the

speed adjusting nut in to increase the speed or out to

decrease the speed.

The engine speed droop from no-load to full-load

should be not less than 60 rpm. Check the engine

speed with no-load connected and again after

con-

necting to full

load.

Sensitivity Adjustment: After adjusting thecarburetor

and the governor, adjust the governor sensitivity

(Figure 33). Sensitivity affects the rpm from no load to

full

load.

Moving the governor spring closer to the

shaft makes the governor more sensitive to load

change and decreases the speed change from no load

to full

load.

Observing a frequency meter, adjust the

sensitivity for as close a cycle range as possible

without hunting.

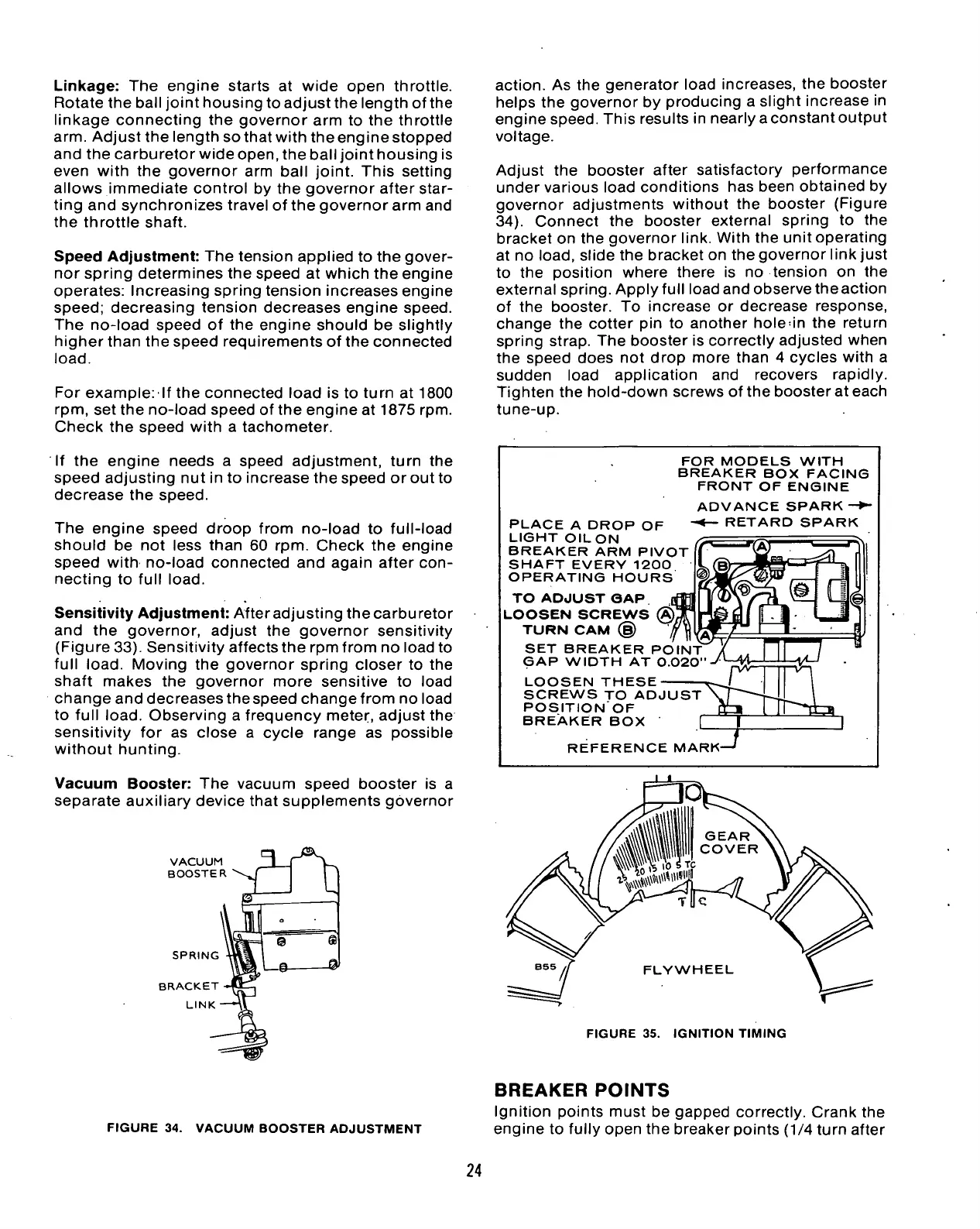

Vacuum Booster: The vacuum speed booster is a

separate auxiliary device that supplements governor

VACUUM I

BOOSTERS

r

'

SPRING

BRACKET

LINK

1

o

@ <

_© 1

action.

As the generator load increases, the booster

helps the governor by producing a slight increase in

engine speed. This results in nearly a constant output

voltage.

Adjust the booster after satisfactory performance

under various load conditions has been obtained by

governor adjustments without the booster (Figure

34).

Connect the booster external spring to the

bracket on the governor link. With the unit operating

at no

load,

slide the bracket on the governor link just

to the position where there is no tension on the

external spring. Apply full load and observe theaction

of the booster. To increase or decrease response,

change the cotter pin to another hole^in the return

spring strap. The booster is correctly adjusted when

the speed does not drop more than 4 cycles with a

sudden load application and recovers rapidly.

Tighten the hold-down screws of the booster at each

tune-up.

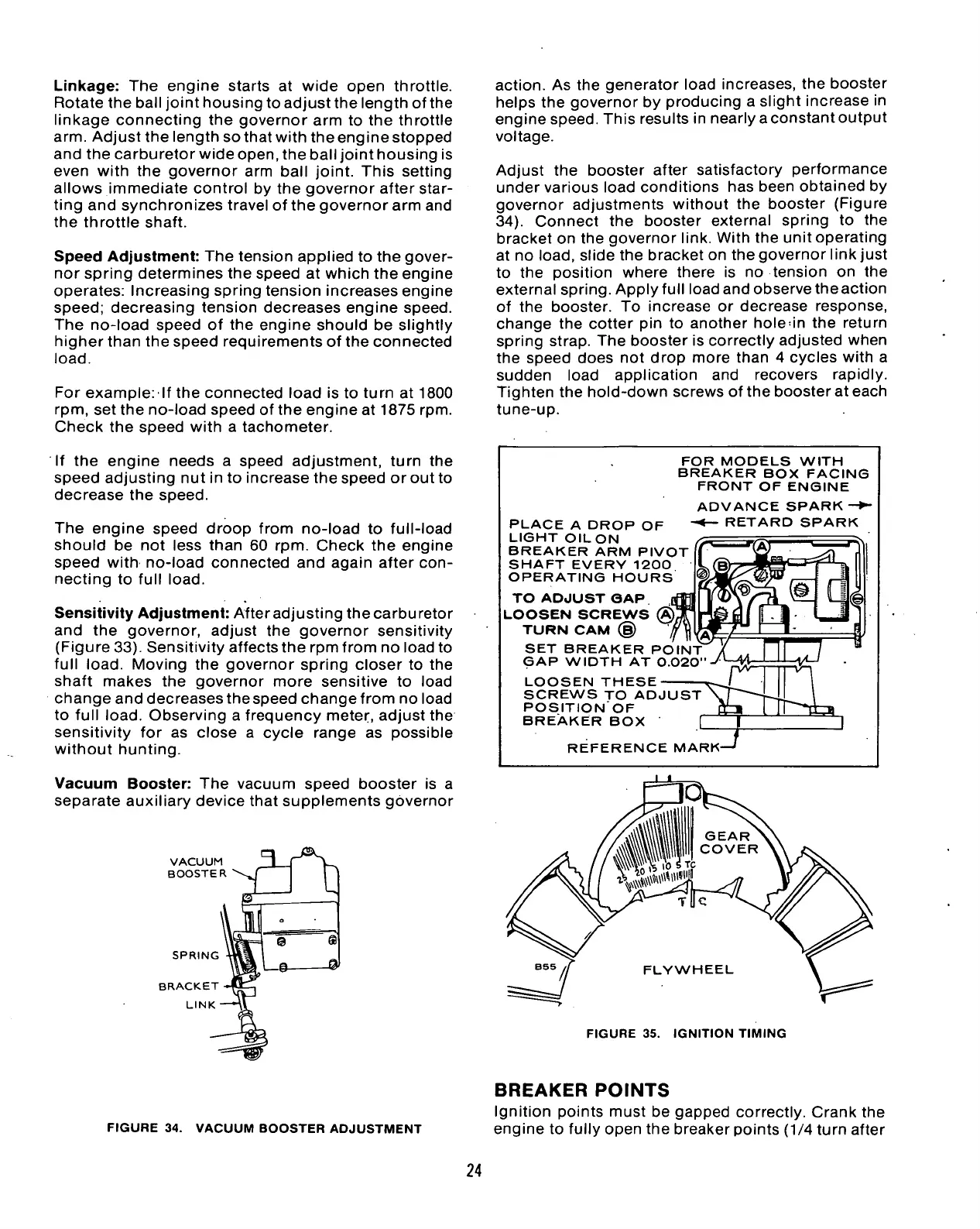

PLACE A DROP OF

LIGHT OILON

BREAKER ARM PIVOT

SHAFT EVERY 1200

OPERATING HOURS

TO ADJUST GAP.

LOOSEN SCREWS

TURN CAM (§)

SET BREAKER POINT

GAP WIDTH AT 0.020"

LOOSEN THESE

SCREWS TO ADJUST

POSITION OF

BREAKER BOX

FOR MODELS WITH

BREAKER BOX FACING

FRONT OF ENGINE

ADVANCE SPARK—

RETARD SPARK

REFERENCE MARK

FIGURE 35. IGNITION TIMING

FIGURE 34. VACUUM BOOSTER ADJUSTMENT

BREAKER

POINTS

Ignition points must be gapped correctly. Crank the

engine to fully open the breaker points (1/4 turn after

24

Loading...

Loading...