5. Restrictions imposed

shutters

or

filters

by screens, louvers,

6. Prevailing wind direction.

Remember that

a

required volume

of air

must reach

the unit, absorb

the

heat,

and be

discharged away

from

the

installation. Pressure cooled units need

an

inlet vent with

an

unrestricted opening

of at

least two

square feet.Use auxiliary fans

to

increase

air

flow

to

units installed

in

small, poorly ventilated rooms.

The

fan size

and

location should

be

such that the

air

inlet

to

the

engine does

not

exceed 120°

F

when running

at

full rated

load.

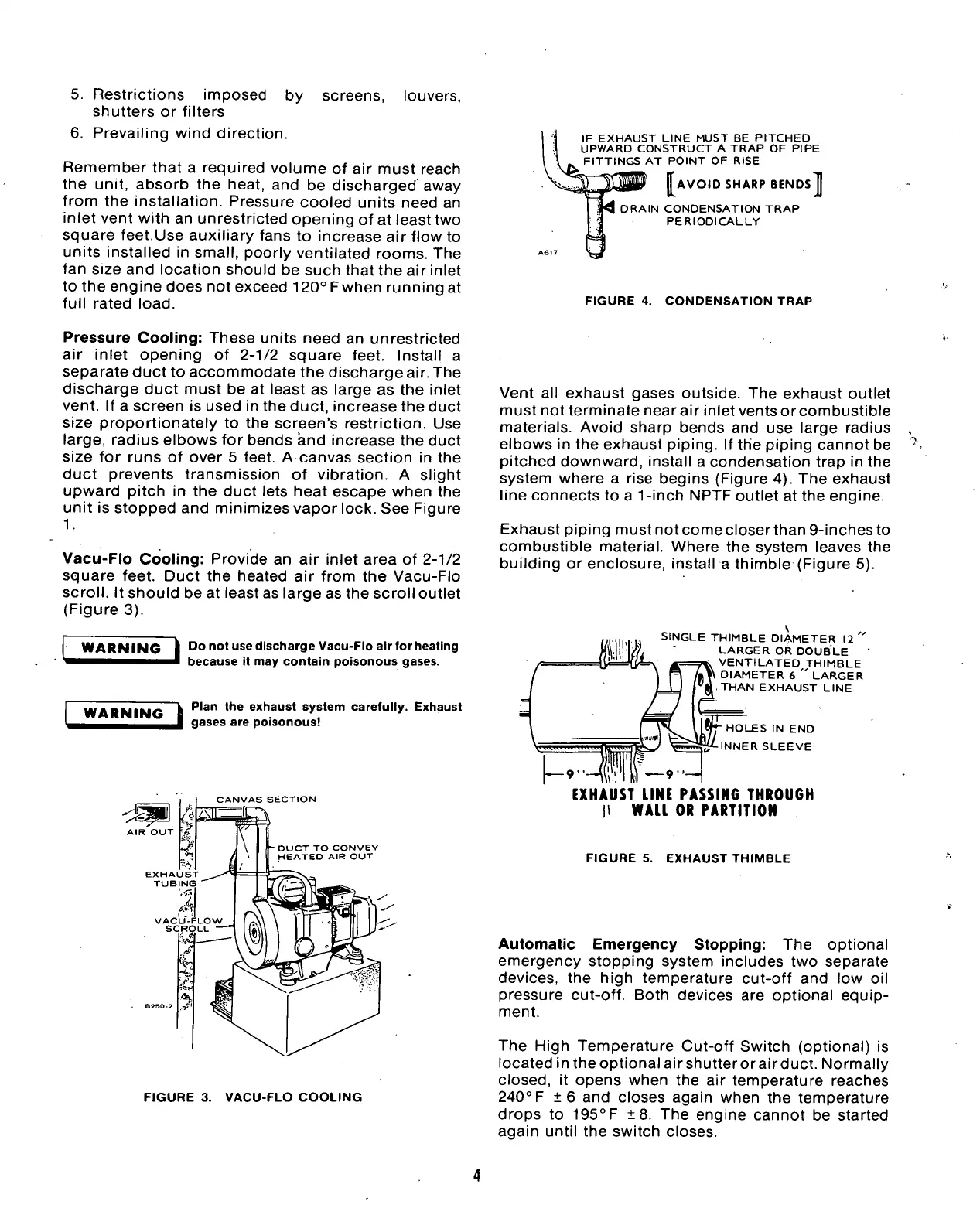

IF EXHAUST LINE MUST

BE

PITCHED

UPWARD CONSTRUCT

A

TRAP

OF

PIPE

FITTINGS

AT

POINT

OF

RISE

AVOID SHARP BENDS

4 DRAIN CONDENSATION TRAP

PERIODICALLY

]

FIGURE

4.

CONDENSATION TRAP

Pressure Cooling: These units need

an

unrestricted

air inlet opening

of 2-1/2

square feet. Install

a

separate duct

to

accommodate the discharge air. The

discharge duct must

be at

least

as

large

as the

inlet

vent.

If a

screen

is

used

in

the duct, increase the duct

size proportionately

to the

screen's restriction.

Use

large,

radius elbows

for

bends and increase

the

duct

size

for

runs

of

over

5

feet.

A

canvas section

in the

duct prevents transmission

of

vibration.

A

slight

upward pitch

in the

duct lets heat escape when

the

unit

is

stopped

and

minimizes vapor lock. See Figure

1.

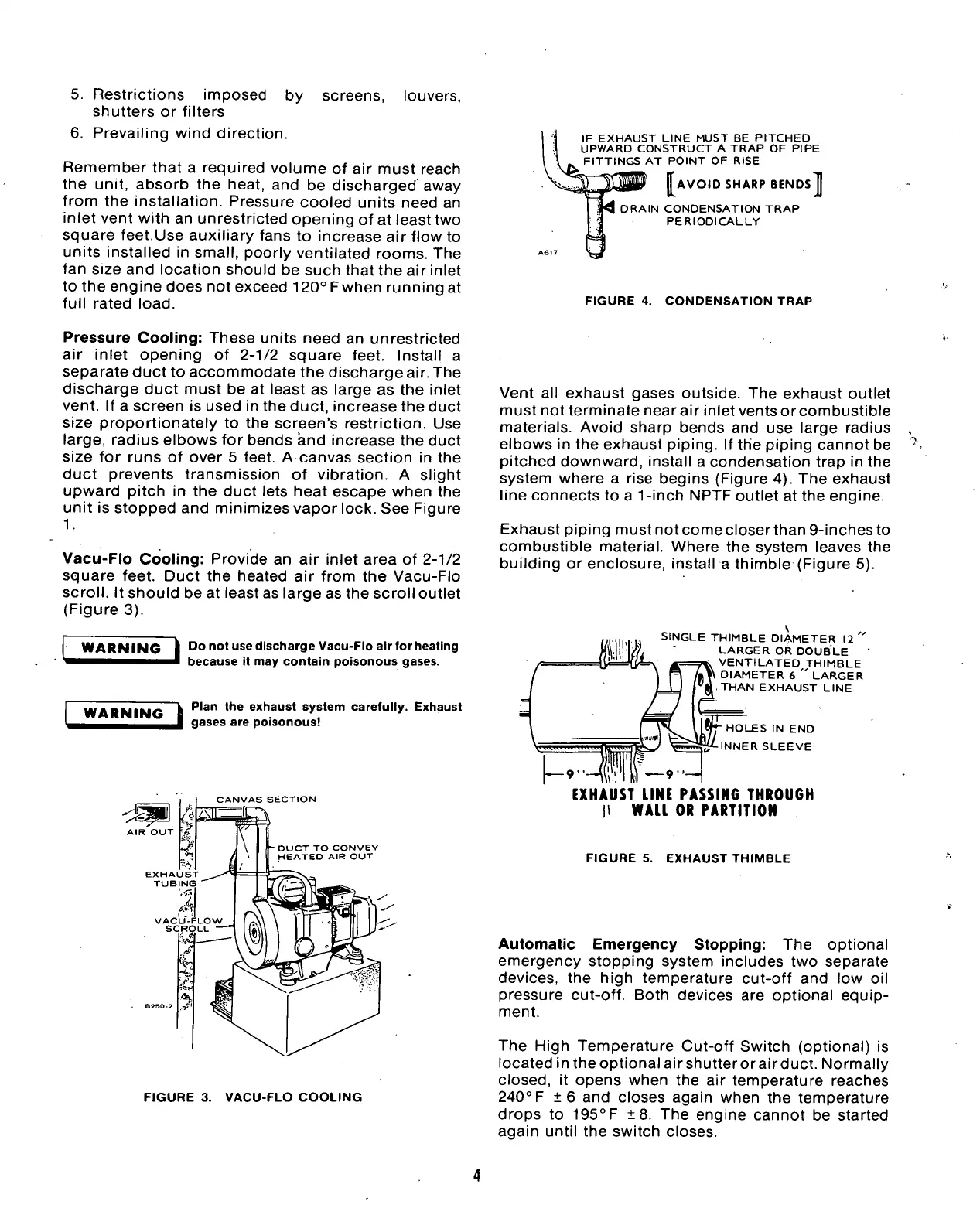

Vacu-Flo Cooling: Provide

an air

inlet area

of

2-1/2

square feet. Duct

the

heated

air

from

the

Vacu-Flo

scroll.

It

should

be

at

least as large as the scroll outlet

(Figure

3).

WARNING

Do not use discharge Vacu-Flo

air

for heating

because

it

may

contain poisonous gases.

WARNING

Plan

the

exhaust system carefully. Exhaust

gases

are

poisonous!

CANVAS

SECTION

DUCT TO CONVEY

HEATED

AIR

OUT

FIGURE

3.

VACU-FLO COOLING

Vent

all

exhaust gases outside.

The

exhaust outlet

must not terminate near

air

inlet vents or combustible

materials. Avoid sharp bends

and use

large radius

elbows

in

the

exhaust piping.

If

the piping cannot

be

pitched downward, install

a

condensation trap

in the

system where

a

rise begins (Figure 4).

The

exhaust

line connects

to a

1-inch

NPTF outlet

at

the

engine.

Exhaust piping mustnotcomecloserthan9-inchesto

combustible material. Where

the

system leaves

the

building

or

enclosure, install

a

thimble (Figure

5).

SINGLE THIMBLE DIAMETER

12

"

LARGER

OR

DOUBLE

VENTILATED THIMBLE

'•W DIAMETER

6 "

LARGER

THAN EXHAUST LINE

HOLES

IN END

INNER SLEEVE

EXHAUST

LINE

PASSING

THROUGH

|l

WALL

OR PARTITION

FIGURE

5.

EXHAUST THIMBLE

Automatic Emergency Stopping:

The

optional

emergency stopping system includes

two

separate

devices,

the

high temperature cut-off

and low oil

pressure cut-off. Both devices

are

optional equip-

ment.

The High Temperature Cut-off Switch (optional)

is

located in the optional air shutter or air duct. Normally

closed,

it

opens when

the air

temperature reaches

240°

F

±6 and

closes again when

the

temperature

drops

to

195°F

±8. The

engine cannot

be

started

again until

the

switch closes.

Loading...

Loading...