®-

9°°

ELBOW

®

^

~

»—NIPPLE®

JL^REDUCING BUSHINOQ

(OPTIONAL!

GAS REGULATOR

@

GAS HOSE

(fi)

HALF PIPE NIPPLE©

EARLIER MODELS

HAD ADDITIONAL

OUTLET HERE WITH

3A" PIPE PLUG.

^ PIPE PLUG

8

-ADJUSTING SCREW

©

VENT ©-INSTALL AFTER ADJUSTMENT

MANUAL SHUT

OFF

GAS SOLENOID VALVE

4 GAS SUPPLY LINE

•

DRY

FUEL

FILTER

FIGURE

6.

CONNECTIONS

FOR GAS

LINE

The

Low Oil

Pressure Circuit (optional) includes

a

non-adjustable

low oil

pressure switch

and

cen-

trifugal switch located

on the

engine and

a

latching

relay

in the

control box. The circuit shuts the engine

down

if oil

pressure drops below

7 ±

1

psi and

prevents

it

from restarting until the operator pushes a

reset button

on the

control

box.

If

low oil

pressure occurs, the pressure switch closes,

completing the relay coil circuit. The relay pulls in and

latches after 15

to

20 seconds. The centrifugal switch

is required

to

prevent the circuit from latching during

the engine starting cycle, before

oil

pressure builds

up.

FUEL

Fuel Connection: Forgasoline-fueled generating sets

other than

the

contractor and portable models which

havetheirown fuel tank, connectafuel line to thefuel

pump inlet which

is

threaded

1/8-inch

NPTF

(National Pipe Thread Female).

Use a

flexible line

next

to

the unit

to

prevent transmission

of

vibration

to

the fuel line.

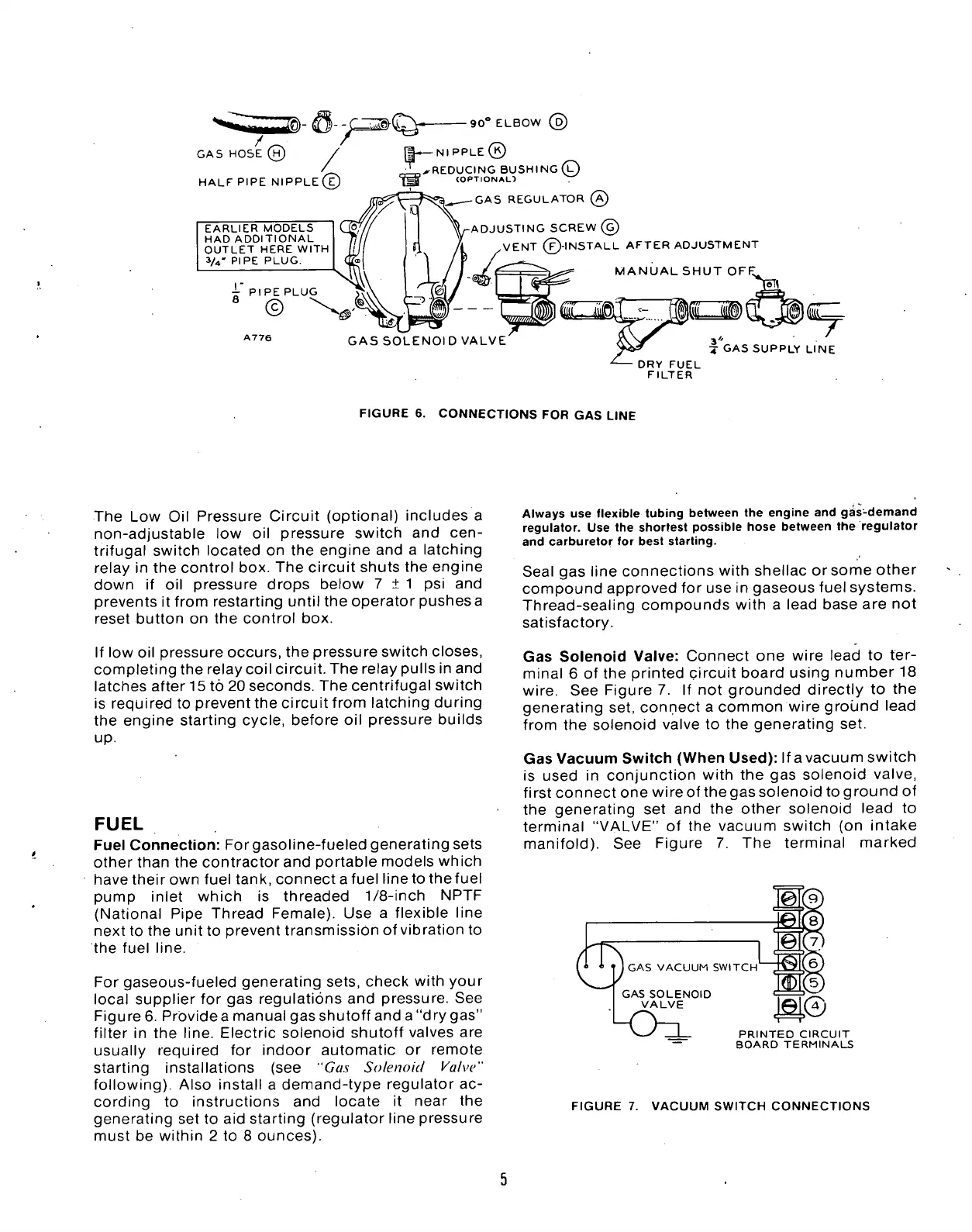

For gaseous-fueled generating sets, check with your

local supplier

for gas

regulations and pressure.

See

Figure 6. Provide a manual gas shutoff and a "dry gas"

filter

in the

line. Electric solenoid shutoff valves

are

usually required

for

indoor automatic

or

remote

starting installations

(see "Gas

Solenoid Valve"

following). Also install

a

demand-type regulator

ac-

cording

to

instructions

and

locate

it

near

the

generating

set to

aid starting (regulator line pressure

must

be

within

2 to 8

ounces).

Always use flexible tubing between the engine and gSs-demand

regulator. Use the shortest possible hose between the regulator

and carburetor for best starting.

Seal

gas

line connections with shellac

or

some other

compound approved

for

use

in

gaseous fuel systems.

Thread-sealing compounds with

a

lead base

are not

satisfactory.

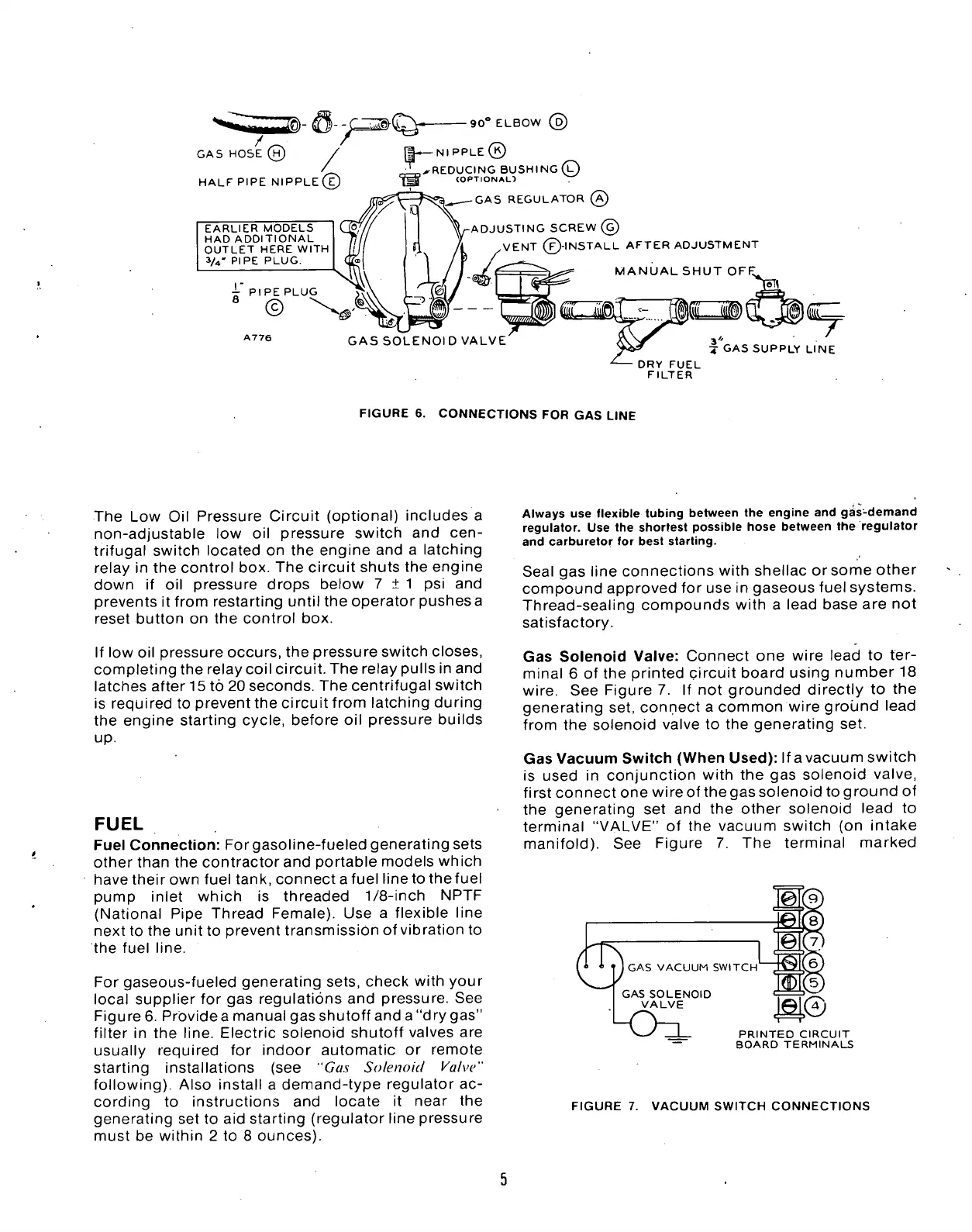

Gas Solenoid Valve: Connect

one

wire lead

to

ter-

minal

6 of

the printed circuit board using number

18

wire.

See

Figure

7. If not

grounded directly

to the

generating set, connect

a

common wire ground lead

from

the

solenoid valve

to the

generating

set.

Gas Vacuum Switch (When Used):

If

a vacuum switch

is used

in

conjunction with

the gas

solenoid valve,

first connect one wire

of

the gas solenoid

to

ground

of

the generating

set and the

other solenoid lead

to

terminal "VALVE"

of the

vacuum switch

(on

intake

manifold).

See

Figure

7. The

terminal marked

^

1

^

GAS VACUUM SWITCH

GAS SOLENOID

VALVE

PRINTED CIRCUIT

BOARD TERMINALS

FIGURE

7.

VACUUM SWITCH CONNECTIONS

Loading...

Loading...