Do

not use galvanized lines, fittings, or fuel

tanks in underground portions of the fuel

system. Hazardous fuel leaks may be caused by electrolytic

corrosion from moisture and chemicals in the

soil

(galvanism).

Some safety ordinances prohibit the use of galvanized materials in

fuel systems and the use of threaded cast iron fittings as well.

The fuel system, located on the service side of the

engine, uses a transfer pump to deliver fuel from the

tank to a high pressure injection pump at about

12

to

14

psi (83-97 kPa). The injection lines deliver fuel to

the injectors at high pressure and act as fuel dis-

tributors to the injectors. The time interval between

individual injectors is varied in the pump by engine

speed. From the injection pump, metered fuel is

forced through a delivery valve to the injector lines at

about 1900 psi (13,110 kPa). When the cylinder air

reaches about 1000°F (538°C) on the compression

stroke, the injector sprays fuel into the hot com-

pressed air where

it

ignites. The delivery valve in the

injection pump and a pintle valve in the injector

assists the precision timed injection of fuel into the

cylinder.

.

Excess fuel is returned to the tank after each injection

cycle by a fuel return line from the nozzle. An adapter

combines the leak-off fuel with the flow-through fuel

from the injection pump. A return line connected at

this point returns the combined fuel back to the fuel

supply tank.

A diesel engine cannot tolerate dirt in the fuel

svstem. It is one of the maior causes of diesel

engine failure. A tiny piece

of

dirt in the Injection system may stop

your unit. When opening any part

of

the fuel system beyond the

secondary fuel filter, place all parts in

a

pan of clean diesel fuel as

they are removed. Before installing new or used parts, flush them

thoroughly, and install while still wet.

FILTER SYSTEM

The sediment bowl has a fine mesh screen which

blocks dirt and water entry into the transfer pump,

Figure 10. The dirt and water remain in the sediment

bowl which should be removed for cleaning as

required. The primary and secondary fuel filters are

replaceable spin-on units that clean the fuel of

extremely fine particles before it goes to the injection

pump.

These filters are mounted

on

a common casting

which bolts to the oil fill tube. Positive filtration is

assured because the engine won’t run when either

filter is loose

or

missing.

Average pore size of the second filter is

.0005

(0.0127 mm) smaller than the first filter. This means

most particles escaping the first filter are trapped in

the second filter.

Water

in

Fuel

Filters: Drain water periodically as

required from both filters. Replace primary filter every

600

hours and secondary filter every

3000

hours.

When replacing filter, tighten screw until gaskets

touch base, then tighten screw

1

to 1-1/2 turns.

FUEL TANK AND

LINES

Where a separate fuel tank

is

used, install

so

the

vertical distance from bottom of the tank to the fuel

pump does not exceed six feet. Auxiliary fuel pumps

are available to provide an additional eight-foot lift.

Avoid gravity feed of fuel to the engine. Provide a

siphon break if tank is above pump. When sharing a

fuel tank, do not connect to an existing line at a point

above the fuel supply level.

These diesel engines require a fuel supply line and a

separate return line. Install the fuel supply line from

tank to the 1/8-inch pipe inlet in the fuel pump.

Connect fuel return line to fitting at injection pump.

See Figure

10.

Use approved flexible fuel lines at the

engine to absorb vibration. Be sure there are no air

leaks in the suction line.

Install a shut-off valve in the tank for service con-

venience.

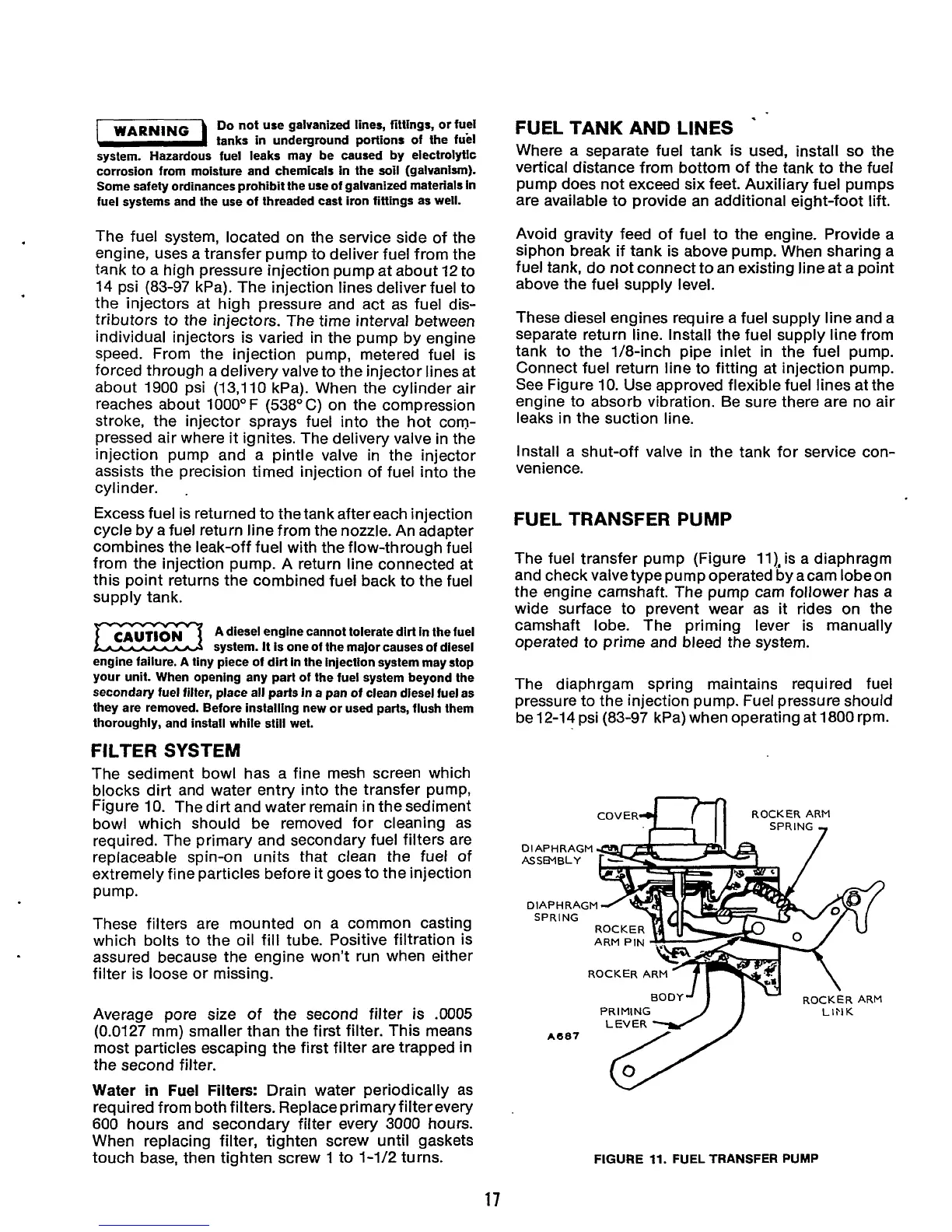

FUEL TRANSFER PUMP

The fuel transfer pump (Figure ll),

is

a diaphragm

and check valve type pump operated

by

a cam lobe on

the engine camshaft. The pump cam follower has a

wide surface to prevent wear as it rides on the

camshaft lobe. The priming lever is manually

operated to prime and bleed the system.

The diaphrgam spring maintains required fuel

pressure to the injection pump. Fuel pressure should

be 12-14 psi (83-97 kPa) when operating at 1800 rpm.

ROCKER

ARM

SPRING

...

COVER

DIAPHRAGM

ASSEMBLY

DIAPHRAGM

SPRING

ROCKER ARM

LINK

FIGURE

11.

FUEL TRANSFER

PUMP

17

Loading...

Loading...