1

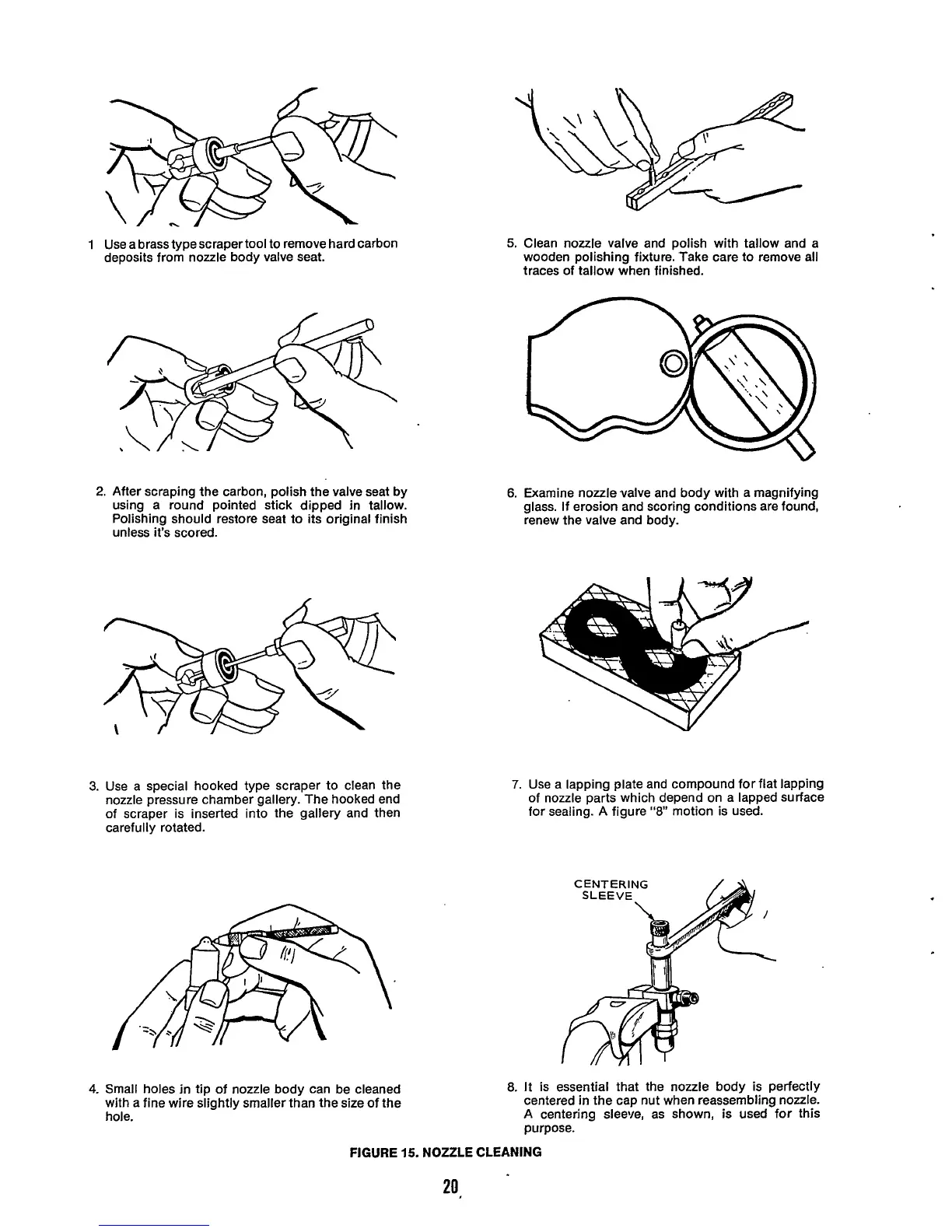

Use a brass type scrapertool to remove hard carbon

deposits from nozzle body valve seat.

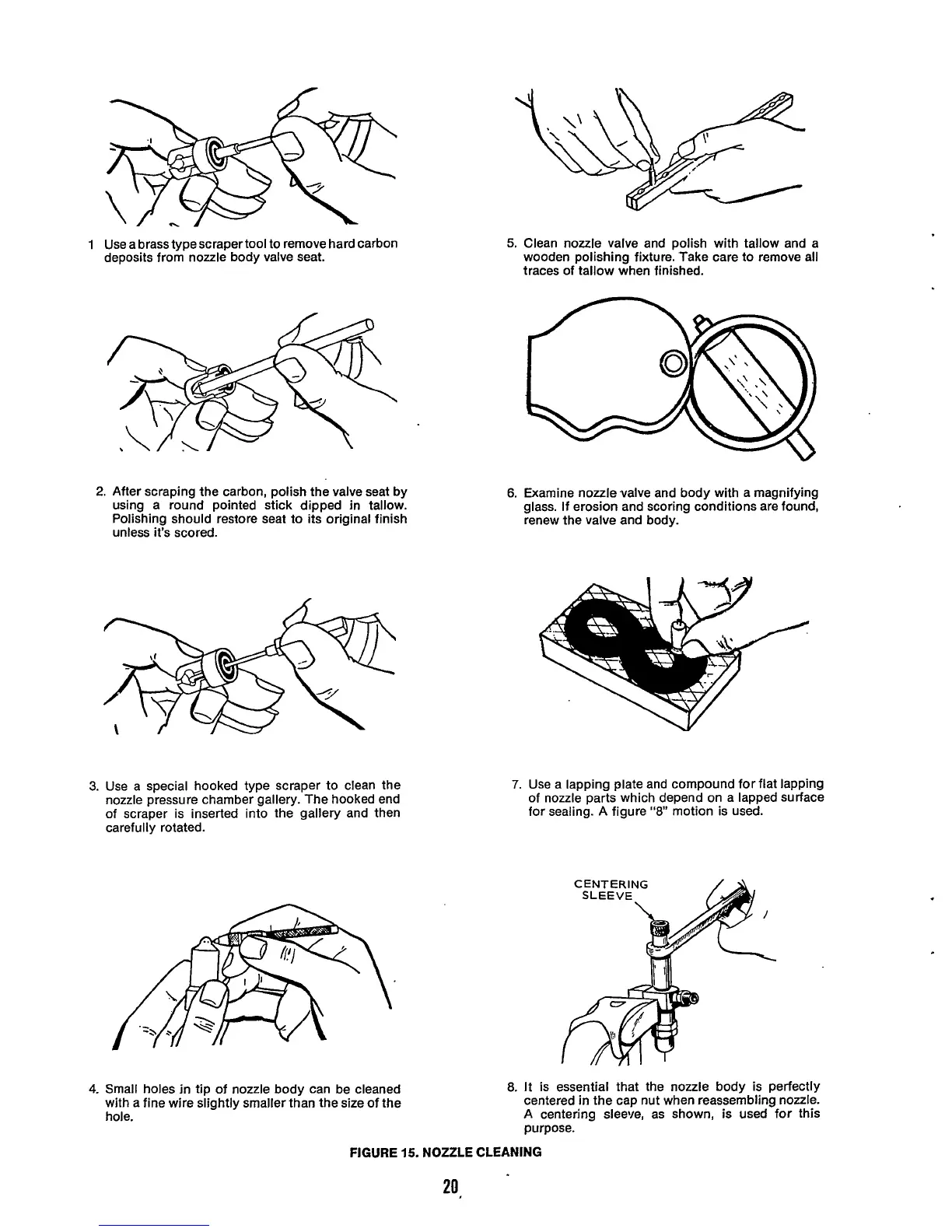

5.

Clean nozzle valve and polish with tallow and a

wooden polishing fixture. Take care to remove all

traces

of

tallow when finished.

2.

After scraping the carbon, polish the valve seat by

using a round pointed stick dipped in tallow.

Polishing should restore seat to its original finish

unless it’s scored.

3.

Use a special hooked type scraper to clean the

nozzle pressure chamber gallery. The hooked end

of scraper is inserted into the gallery and then

carefully rotated.

6.

Examine nozzle valve and body with a magnifying

glass. If erosion and scoring conditions are found,

renew the valve and body.

7.

Use a lapping plate and compound for flat lapping

of nozzle parts which depend on a lapped surface

for sealing.

A

figure

“8’

motion is used.

CENTERING

4.

Small holes in tip

of

nozzle body can be cleaned

with a fine wire slightly smaller than the size

of

the

hole.

8.

It is essential that the nozzle body

is

perfectly

centered

in

the cap nut when reassembling nozzle.

A

centering sleeve, as shown, is used for this

purpose.

FIGURE

15.

NOZZLE CLEANING

20

Loading...

Loading...