Operating Principle

Nozzle operation is as follows:

1. High pressure fuel from theinjection pump enters

the fuel inlet stud and flows down drilled

passages in the body of nozzle holder, Figure

13.

2. Fuel enters fuel duct and pressure chamber of

nozzle assembly. When fuel pressure overcomes

preset pressure of the adjusting spring, the pintle

is forced upward off its seat and a fine mist of fuel

is injected into the pre-combustion chamber

where

it

atomizes and mixes with the hot com-

pressed air.

3.

If compression temperatures are high enough,

the fuel-air mixture ignites. Injection continues

until the spill port clears the top of the metering

sleeve in the injection pump and dumps the high

pressure fuel into the sump allowing the pressure

spring to close the injector and cut off fuel

injection to the cylinder.

Do

not disturb the injector pressureadjusting

screw; it cannot be reset without proper

equipment.

Excess fuel is returned to the tankafter each injection

cycle by a return line from the nozzle.

A

fuel return

fitting combines the return fuel from the injectors with

the flow-through fuel from the injection pump bleed

valve.

A

return line connected at this point returns the

combined fuel back to the fuel supply tank.

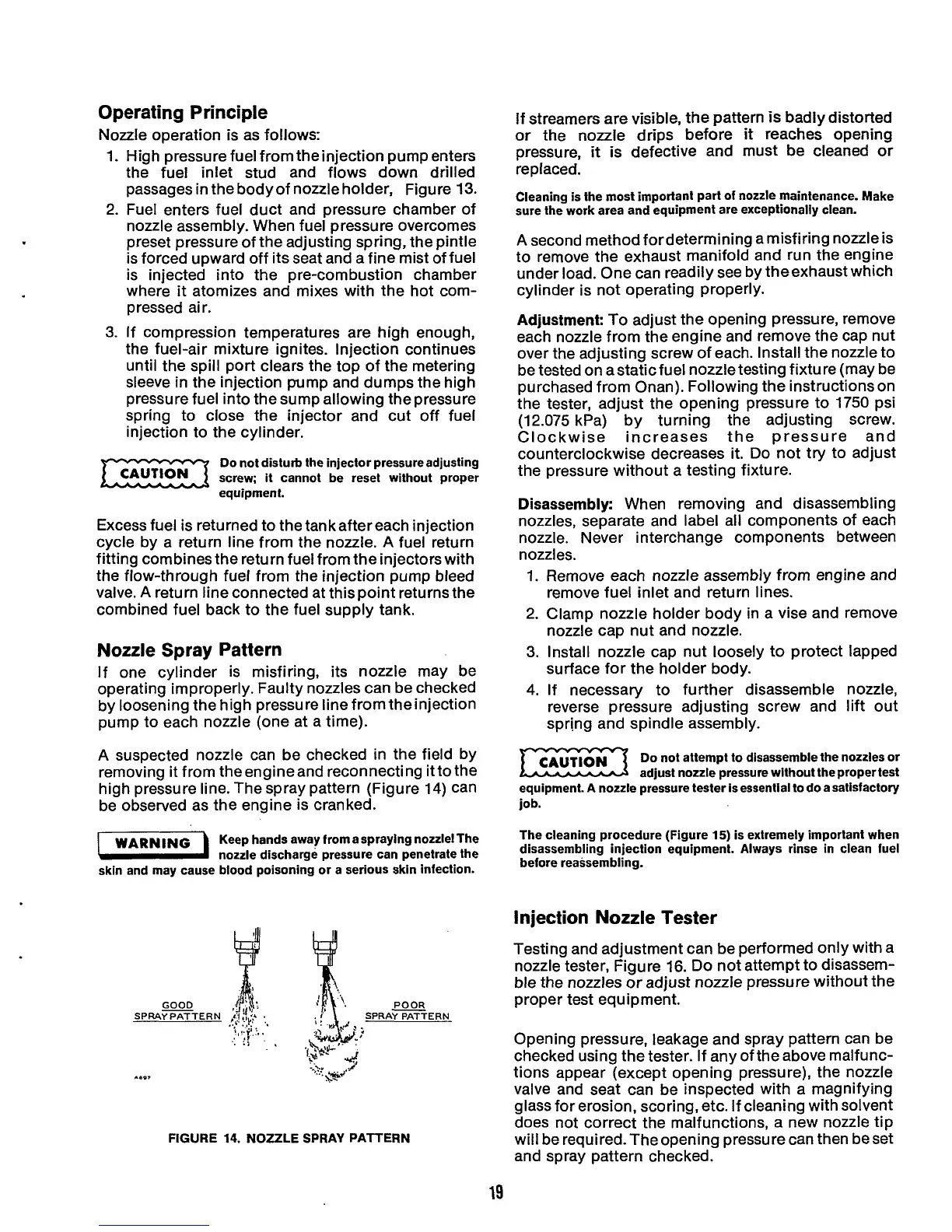

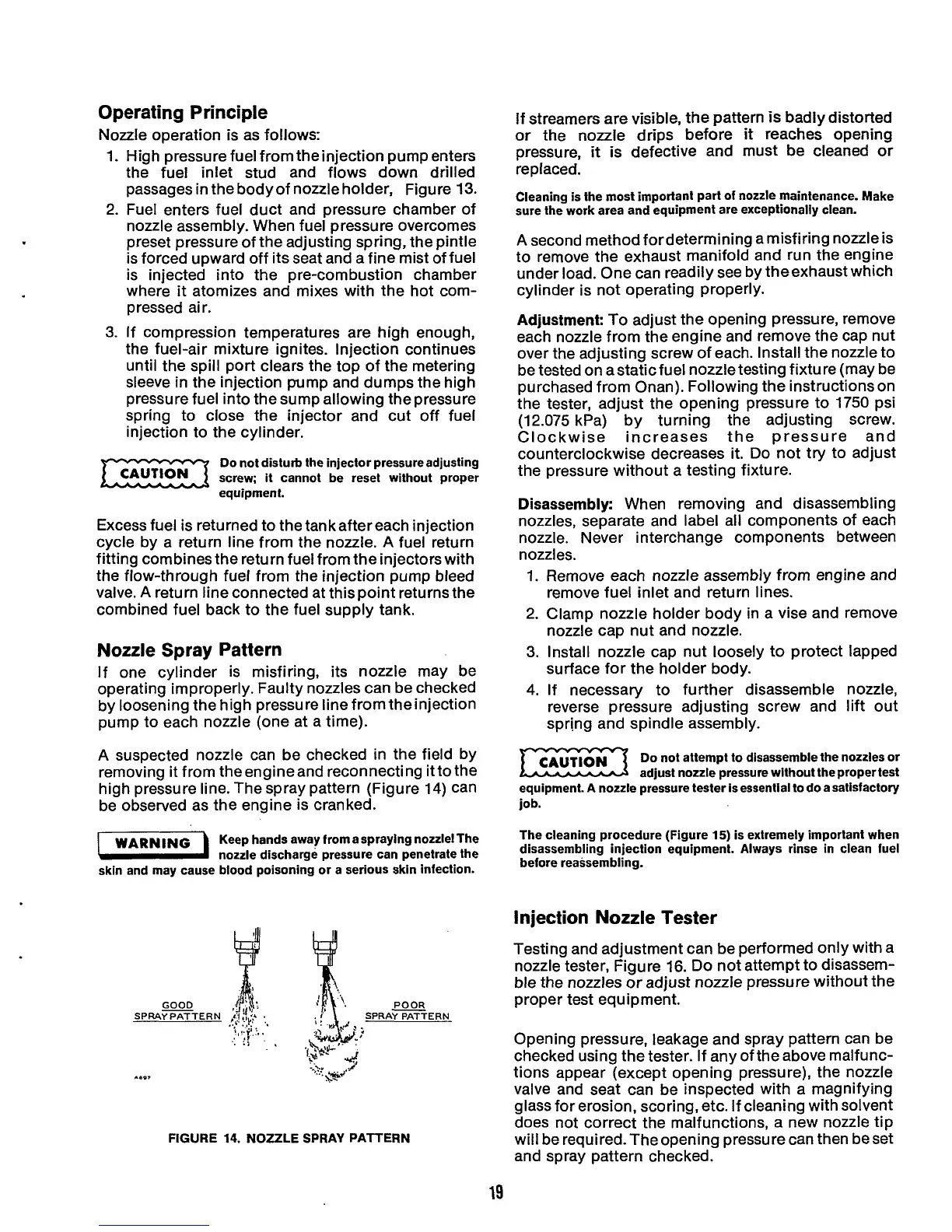

Nozzle Spray Pattern

If one cylinder

is

misfiring, its nozzle may be

operating improperly. Faulty nozzles can be checked

by loosening the high pressure line from theinjection

pump to each nozzle (one at a time).

If streamers are visible, the pattern

is

badly distorted

or

the

nozzle drips before

it

reaches opening

pressure,

it

is defective and must be cleaned or

replaced.

Cleaning is the most important part

of

nozzle maintenance. Make

sure the work area and equipment are exceptionally clean.

A

second method for determining a misfiring nozzle is

to remove the exhaust manifold and run the engine

under load. One can readily see by theexhaust which

cylinder is not operating properly.

Adjustment:

To

adjust the opening pressure, remove

each nozzle from the engine and remove the cap nut

over the adjusting screw of each. Install the nozzle to

be tested on astaticfuel nozzletesting fixture (may be

purchased from Onan). Following the instructions on

the tester, adjust the opening pressure to 1750 psi

(12.075 kPa) by turning the adjusting screw.

Clockwise increases the pressure and

counterclockwise decreases

it.

Do

not try to adjust

the pressure without a testing fixture.

Disassembly:

When removing and disassembling

nozzles, separate and label all components of each

nozzle. Never interchange components between

nozzles.

1. Remove each nozzle assembly from engine and

remove fuel inlet and return lines.

2. Clamp nozzle holder body in a vise and remove

nozzle cap nut and nozzle.

3.

Install nozzle cap nut loosely to protect lapped

surface for the holder body.

4.

If

necessary to further disassemble nozzle,

reverse pressure adjusting screw and lift out

spring and spindle assembly.

Do

not attempt to disassemble the nozzles or

adjust nozzle pressure without the propertest

equipment. A nozzle pressure tester is essential to do a satisfactory

job.

A

suspected nozzle can be checked in the field by

removing it from theengineand reconnecting itto the

high pressure line. The spray pattern (Figure 14) can

be observed as the engine is cranked.

71

Keep hands away fromaspraying nozzle! The

nozzle

discharge

pressure

can

penetrate the

skin and may cause blood poisoning or a serious skin infection.

The Cleaning procedure (Figure

15)

is extremely important when

disassembling injection equipment. Always rinse in clean fuel

before reassembling.

Injection Nozzle Tester

Testing and adjustment can be performed only with a

nozzle tester, Figure

16.

Do

not attempt to disassem-

ble the nozzles or adjust nozzle pressure without the

POOR

proper test equipment.

-

SPRAY PATTERN

:

..I

?!

.

,

Opening pressure, leakage and spray pattern can be

checked using the tester. If any of the above malfunc-

tions appear (except opening pressure), the nozzle

valve and seat can be inspected with a magnifying

glass for erosion, scoring, etc. If cleaning with solvent

does not correct the malfunctions, a new nozzle tip

will be required. Theopening pressure can then beset

and spray pattern checked.

-*.."

,:;.

.@''C

.697

h.

FIGURE

14.

NOZZLE SPRAY PATTERN

Loading...

Loading...