To

test the solenoid, check plunger operation and

current draw with 12-volt input. Current draw with the

plunger up should be about

1

amp. If

it

is much

greater, the contacts did not open.

The solenoid plunger should be adjusted

so

it

fully

stops injection when in the de-energized position. To

adjust the plunger length, screw the hex head cap

screw and jam nut on the plunger bottom

in

or out. If

the plunger sticks, remove the solenoid from its

mounting plate and clean the plunger and recess in

the solenoid.

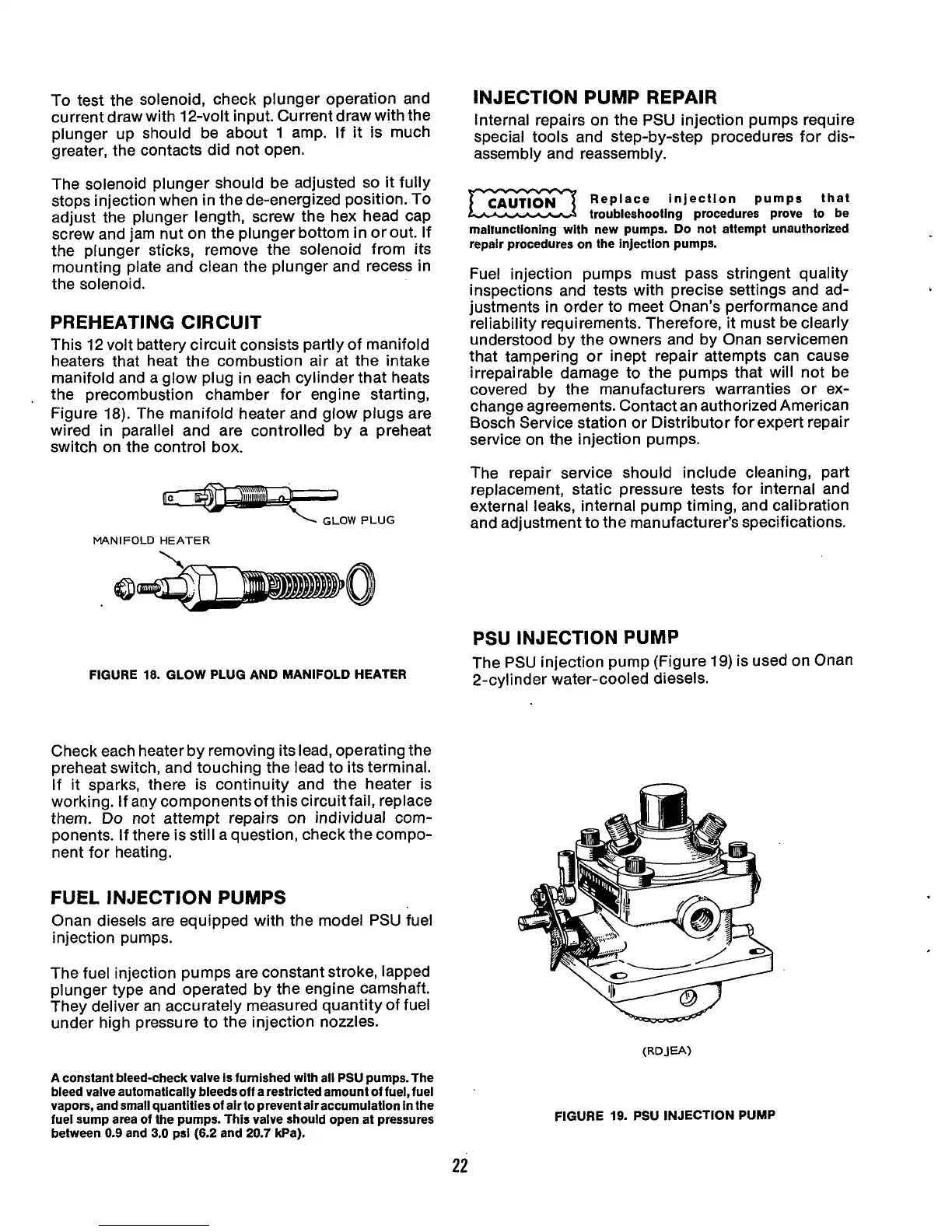

PREHEATING CIRCUIT

This 12 volt battery circuit consists partly of manifold

heaters that heat the combustion air at the intake

manifold and a glow plug in each cylinder that heats

.

the precombustion chamber for engine starting,

Figure

18).

The manifold heater and glow plugs are

wired

in

parallel and are controlled by a preheat

switch on the control box.

GLOW

PLUG

MANIFOLD HEATER

\

FIGURE

18.

GLOW PLUG AND MANIFOLD HEATER

Check each heater by removing its lead, operating the

preheat switch, and touching the lead to its terminal.

If it sparks, there is continuity and the heater is

working. If any componentsof this circuit fail, replace

them.

Do

not attempt repairs on individual com-

ponents. If there is still a question, check the compo-

nent for heating.

FUEL

INJECTION PUMPS

Onan diesels are equipped with the model

PSU

fuel

injection pumps.

The fuel injection pumps are constant stroke, lapped

plunger type and operated by the engine camshaft.

They deliver an accurately measured quantity of fuel

under high pressure to the injection nozzles.

A constant bleed-check valve is furnished with all PSU pumps.The

bleed valve automatically bleedsoff a restricted amount of fuel, fuel

vapors, and small quantities of air to prevent air accumulation in the

fuel sump area of the pumps. This valve should open at pressures

between

0.9

and

3.0

psi

(6.2

and

20.7

Wa).

INJECTION PUMP REPAIR

Internal repairs on the

PSU

injection pumps require

special tools and step-by-step procedures for dis-

assembly and reassembly.

Replace injection pumps that

troubleshooting procedures prove to be

malfunctioning with new pumps. Do not attempt unauthorized

repair procedures on the injection pumps.

Fuel injection pumps must pass stringent quality

inspections and tests with precise settings and ad-

justments in order to meet Onan’s performance and

reliability requirements. Therefore, it must be clearly

understood by the owners and by Onan servicemen

that tampering or inept repair attempts can cause

irrepairable damage to the pumps that will not be

covered by the manufacturers warranties or ex-

change agreements. Contact an authorized American

Bosch Service station or Distributor for expert repair

service on the injection pumps.

The repair service should include cleaning, part

replacement, static pressure tests for internal and

external leaks, internal pump timing, and calibration

and adjustment to the manufacturer’s specifications.

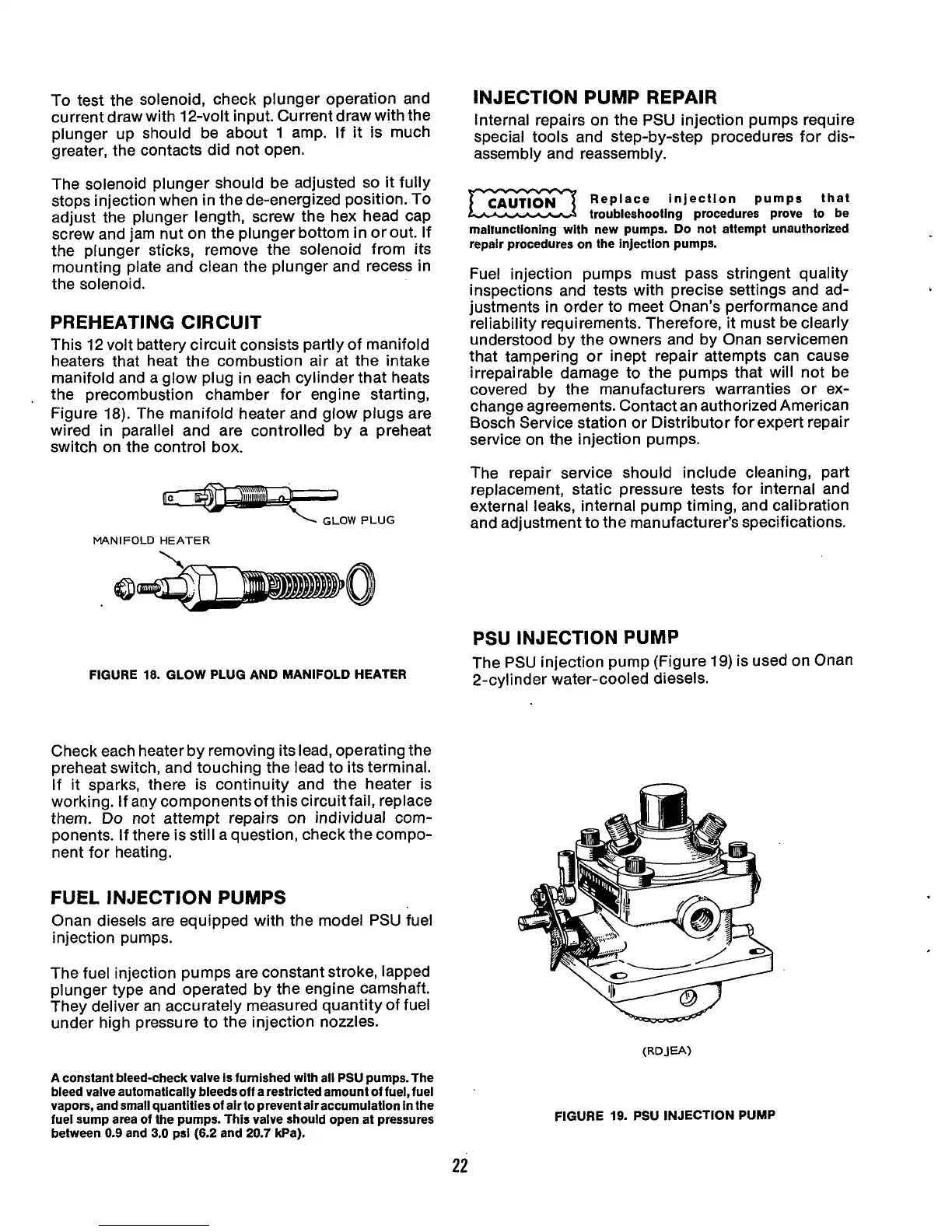

PSU INJECTION PUMP

The

PSU

injection pump (Figure

19)

is used on Onan

2-cylinder water-cooled diesels.

FIGURE

19.

PSU INJECTION PUMP

22

Loading...

Loading...