TABLE

1.

TIMING

BUlTONS

16orS

15

or

R

14orP

13

or

N

12orM

GROUP

1

I

GROUP

2

I

CODE

I

PARTNO.

I

SI

147-0186

147-0187

147-0188

147-0189

147-0190

I

I

I

Inch

~~

-134

.131

-128

.125

.122

I

CODE

I

PARTNO.

I

S

mm

147-0161

Button

12

or

Y

is

the mid-range

of

the button sizes used the most.

The button dimension is determined by the number or letter

stamped on its side, Figure

25.

BUTTON WITH CODE LETTER

OR

NUMBER STAMPED ON

IT.

FIGURE

25.

TAPPET BUTTON CODE

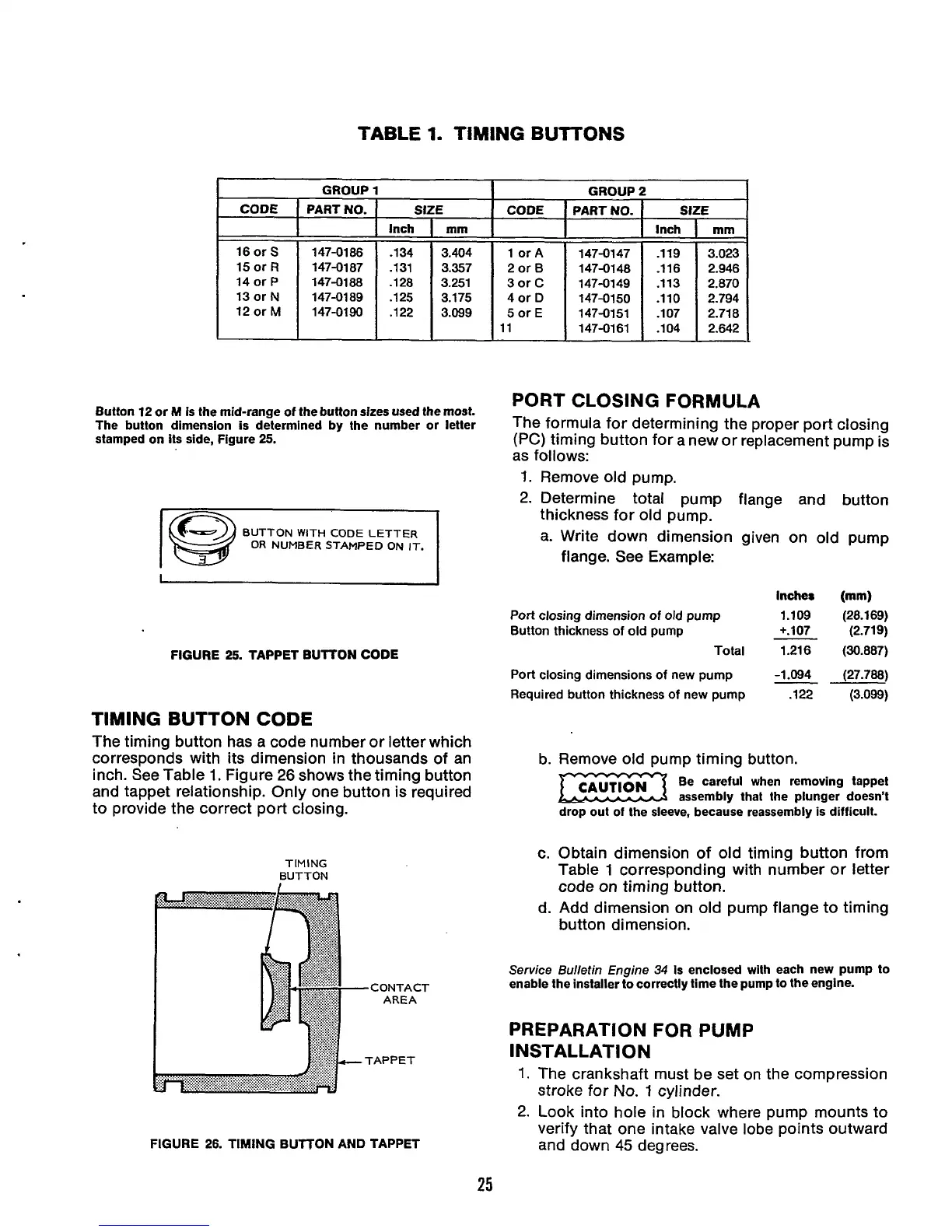

TIMING BUTTON

CODE

The timing button has a code number or letter which

corresponds with its dimension in thousands of an

inch. See Table

1.

Figure

26

shows the timing button

and tappet relationship. Only one button is required

to provide the correct port closing.

TIMING

BUTTON

FIGURE

26.

TIMING BUTTON AND TAPPET

3.023

2.946

2.870

2.794

2.718

2.642

PORT CLOSING FORMULA

The formula for determining the proper port closing

(PC) timing button for a new or replacement pump is

as follows:

1.

Remove old pump.

2.

Determine total pump flange and button

thickness for old pump.

a. Write down dimension given on old pump

flange. See Example:

Inches (mm)

Port

closing dimension

of

old pump

1.109 (28.169)

Bu!ton thickness

of

old pump

+.lo7 (2.719)

Total

1.216 (30.887)

Port

closing dimensions

of

new pump

-1.094 (27.788)

Required button thickness

of

new pump

.122 (3.099)

b. Remove old pump timing button.

Be careful when removing tappet

assembly that the plunger doesn't

drop out of the sleeve, because reassembly is difficult.

c. Obtain dimension of old timing button from

Table

1

corresponding with number or letter

code on timing button.

d. Add dimension on old pump flange to timing

button dimension.

Service Bulletin Engine

34

Is enclosed with each new pump to

enable the installer to correctly time the pump to the engine.

PREPARATION

FOR

PUMP

INSTALLATI ON

1.

The crankshaft must be set on the compression

stroke

for

No.

1

cylinder.

2.

Look into hole in block where pump mounts to

verify that one intake valve lobe points outward

and down

45

degrees.

25

Loading...

Loading...