When the tappet slips off each lobe of the camshaft,

the spring loaded plunger

is

forced down opening the

fuel supply

port

to the fuel sump. This allows fuel

under low pressure from the transfer pump and fuel

sump to

fill

the cavity between the top end of the

plunger and the delivery valve. The plunger is then

ready for the up stroke.

Metering Sleeve Operation

The metering sleeve is positioned by the operating

lever of the governor control unit, Figure

22.

An

eccentric pin on the end of the control shaft engages a

slot in the metering sleeve

so

that a slight rotation of

the control shaft causes the sleeve to ride up or down

on the plunger. As the camshaft and face gear rotate,

the drive key and a vertical

slot

in the face gear

transmit rotation to the plunger. Rotating the plunger

aligns the plunger outlet groove with the proper

injection line outlet for the injector to be fired on each

pump stroke.

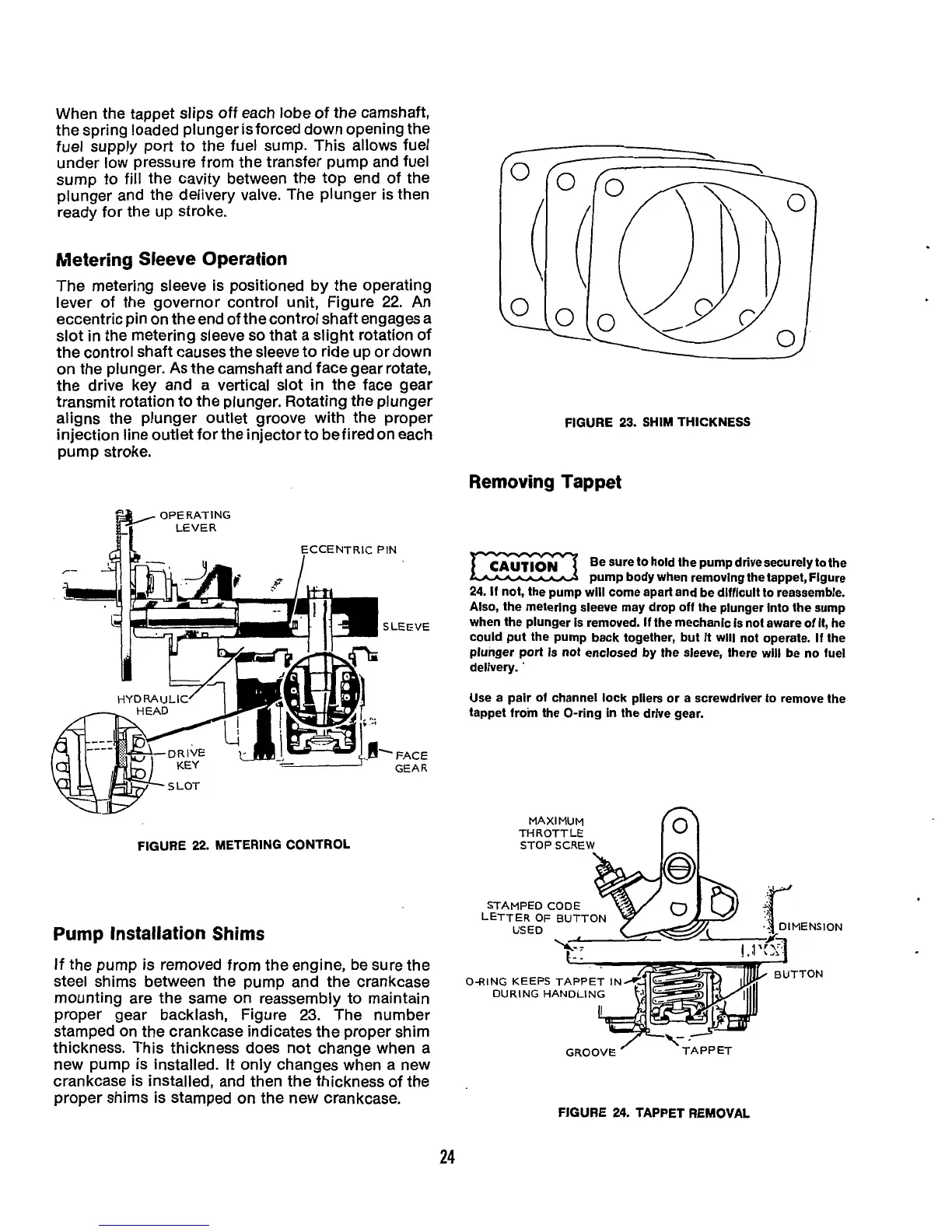

FIGURE

23.

SHIM

THICKNESS

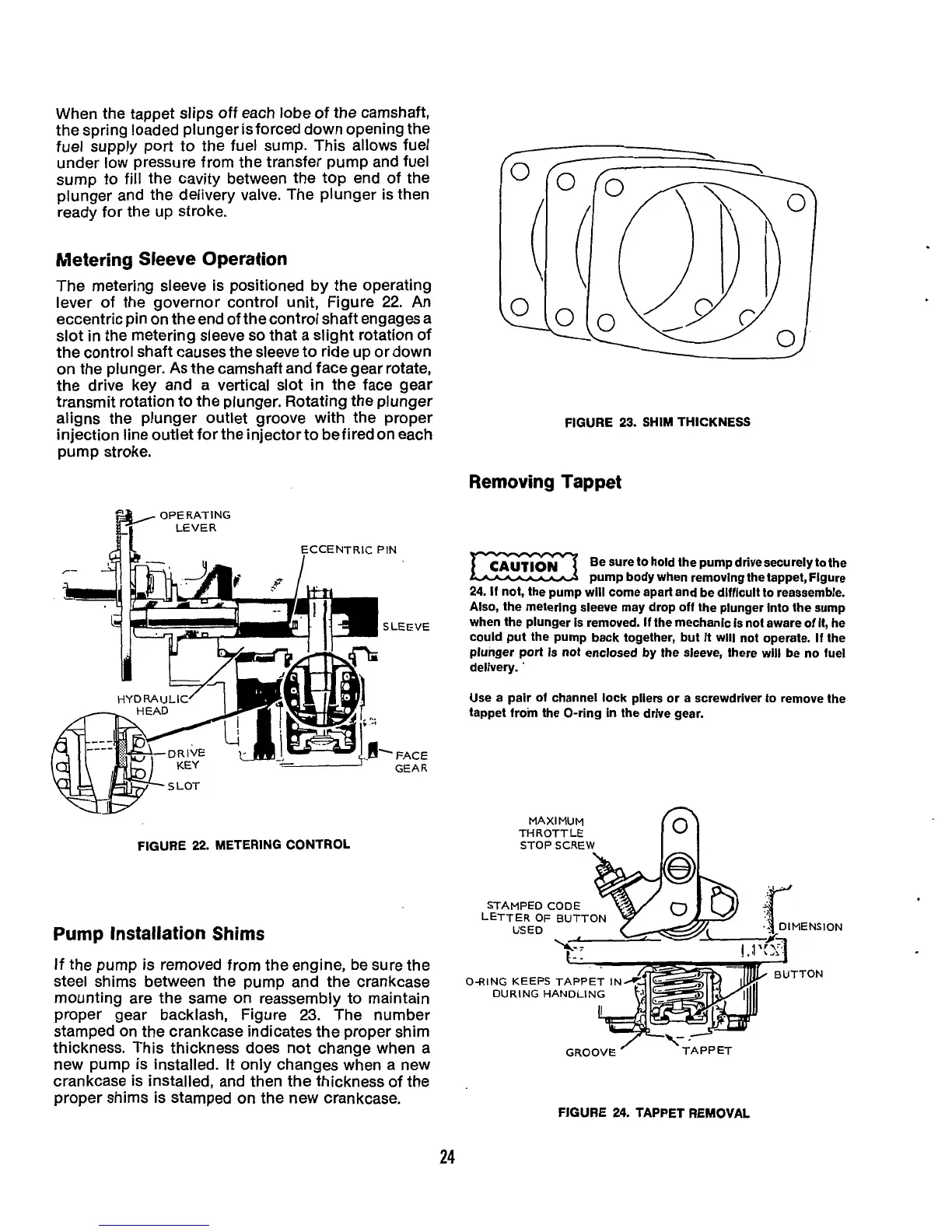

Removing Tappet

Be sure to hold the pump drive securely to the

pump body when removing the tappet, Figure

24.

If

not, the pump

will

come apart and be difficult to reassemble.

Also, the metering sleeve may drop

off

the plunger into the sump

when the plunger is removed.

If

the mechanic

Is

not aware

of

it, he

could put the pump back together, but it will not operate.

If

the

plunger port is not enclosed by the sleeve, there will be no fuel

delivery.

'

SLEEVE

Use a pair

of

channel

lock

pliers or a screwdriver to remove the

tappet

from

the O-ring

in

the drive gear.

MAXIMUM

THROTTLE

STOP SCREW

STAMPED CODE

LETTER

OF

BUTTON

USED

FIGURE

22.

METERING CONTROL

Pump Installation Shims

If

the pump is removed from the engine, be sure the

steel shims between the pump and the crankcase

mounting are the same on reassembly to maintain

proper gear backlash, Figure

23.

The number

stamped on the crankcase indicates the proper shim

thickness. This thickness does not change when a

new pump is installed.

It

only changes when a new

crankcase is installed, and then the thickness of the

proper shims is stamped on the new crankcase.

TTON

O-RING KEEPS TAPPET IN

DURING HANDLING

FIGURE

24.

TAPPET REMOVAL

24

Loading...

Loading...