FLYWHEEL

The flywheel is a tapered fit on the crankshaft.

Improvise a puller, using at least a 7/16-inch bar

(11.113 mm), and drill two 7/16-inch (11.113 mm)

holes 2-7/8 inches (73.025 mm) between centers.

Loosen the flywheel mounting screw a few turns.

Place bar against the flywheel screw and attach bar,

using two 3/8-16 thread screws

in

the holes provided

in flywheel. Alternately tighten the screws until

flywheel is free.

FLYWHEEL REPLACEMENT

Replacement flywheels are supplied without the

timing markings because each flywheel must befitted

to

its engine. The only accurate method of determing

the top dead center (TDC) and port closing points is

to

measure the piston travel. This is a critical

measurement and should be attempted only with

accurate, dependable equipment.

With the flywheel mounted, remove the head and

install a depth gauge over the front piston. Rotate the

flywheel to find the TDC position on the compression

stroke and mark this point on the flywheel. Next, turn

the flywheel counterclockwise

until

the piston drops

exactly 0.128 inch (3.25 mm). Mark both TDC and

piston drop to PC point on the flywheel.

Ring

Gear:

To

remove the ring gear, if damaged, saw

part way through, then break it using acold chisel and

heavy hammer.

To

install a new ring gear, place

it

in

an oven heated to

380"

F

-

400"

F

(192"

to 204"

C)

for 30 to 40 minutes.

Do

not heat with a torch or ring gear may be

warped.

When heated properly, the ring will fall into place on

the flywheel. If it does not go on all the way by itself,

drive

it

into place with a hammer.

Do

itfastand do not

damage the gear teeth. The ring will contract rapidly

and may shrink to the flywheel before

it

is

in

place. If

this occurs, a new ring gear may be required.

GEAR

COVER

To remove the gear cover, detach the uppergovernor

ball joint. Remove thegovernorspeed-adjustment nut

and governor spring bracket.

Remove the screws holding the gear cover to the

crankcase. To loosen the gear cover, tap

it

with a soft

hammer.

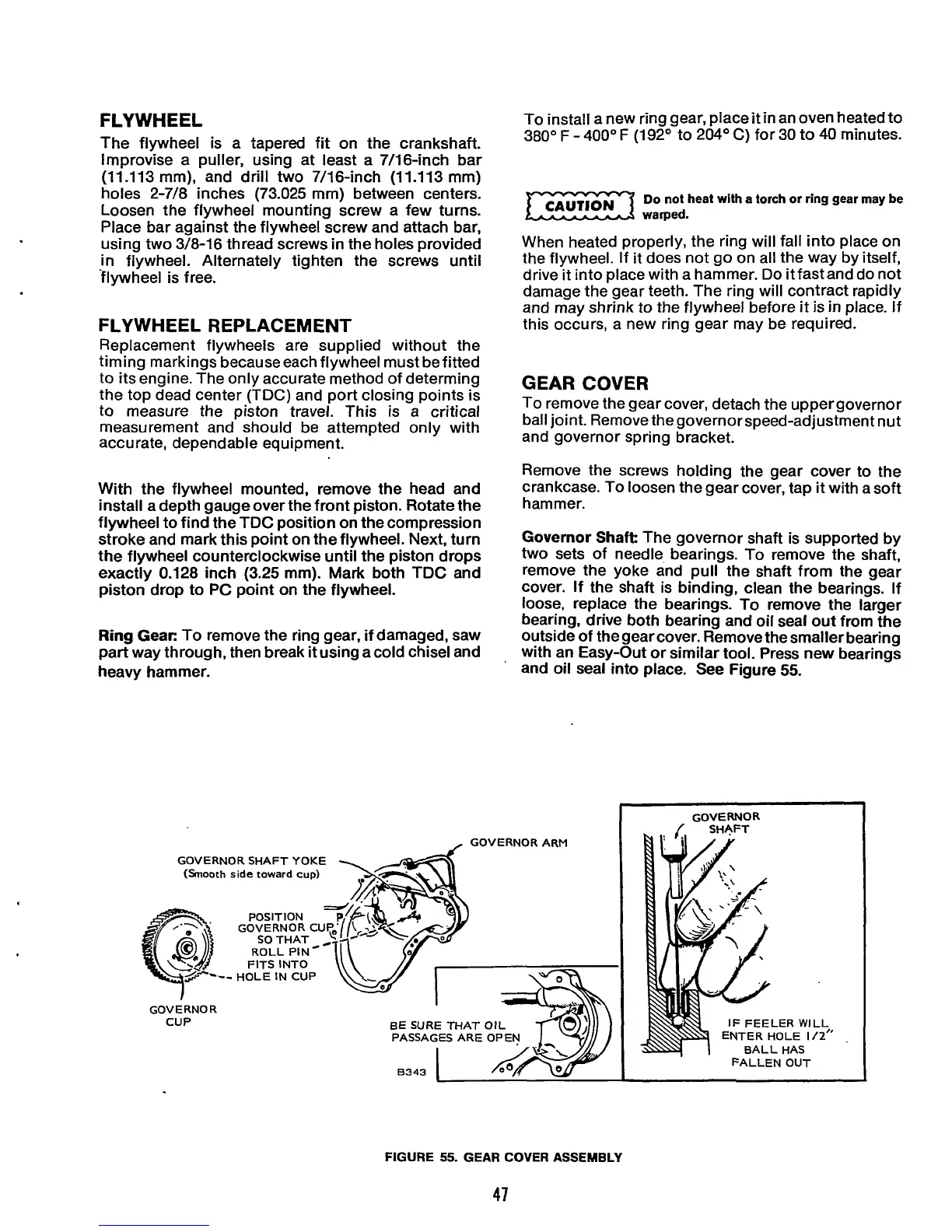

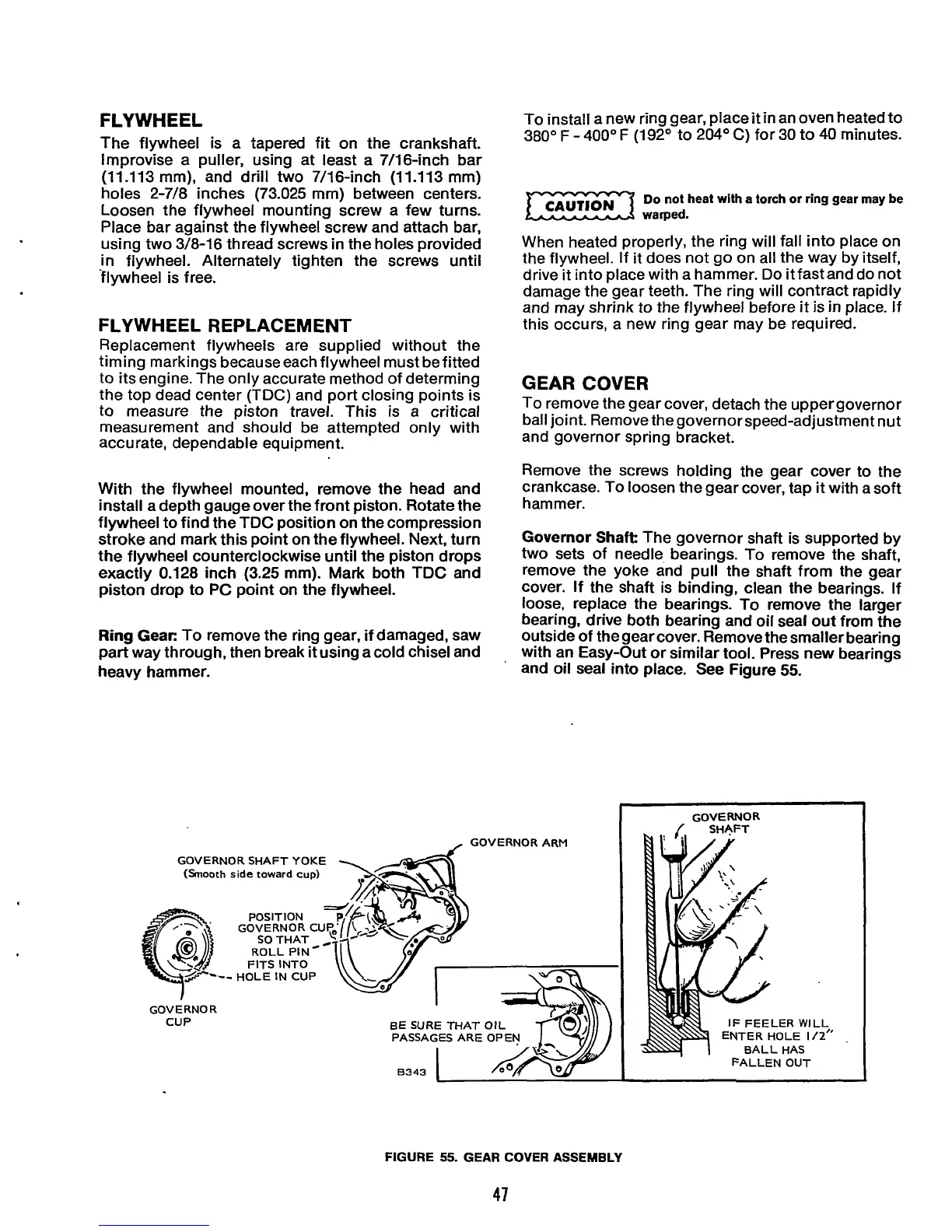

Governor

Shaft

The governor shaft is supported by

two sets of needle bearings.

To

remove the shaft,

remove the yoke and pull the shaft from the gear

cover. If the shaft is binding, clean the bearings. If

loose, replace the bearings. To remove the larger

bearing, drive both bearing and oil seal out from the

outside

of

the gear cover. Remove the smaller bearing

with an Easy-Out

or

similar tool. Press new bearings

and oil seal into place. See Figure

55.

GOVERNOR

GOVERNOR ARM

.

GOVERNOR SHAFT

YOKE

(Smooth

side

toward

cup)

FITS

INTO

GOVERNOR

CUP BE

SURE

THAT

OIL

PASSAGES ARE OPEN

I

8343

IF

FEELER

WILL

ENTER HOLE

112"

,

BALL HAS

FALLEN OUT

FIGURE

55.

GEAR

COVER

ASSEMBLY

47

Loading...

Loading...