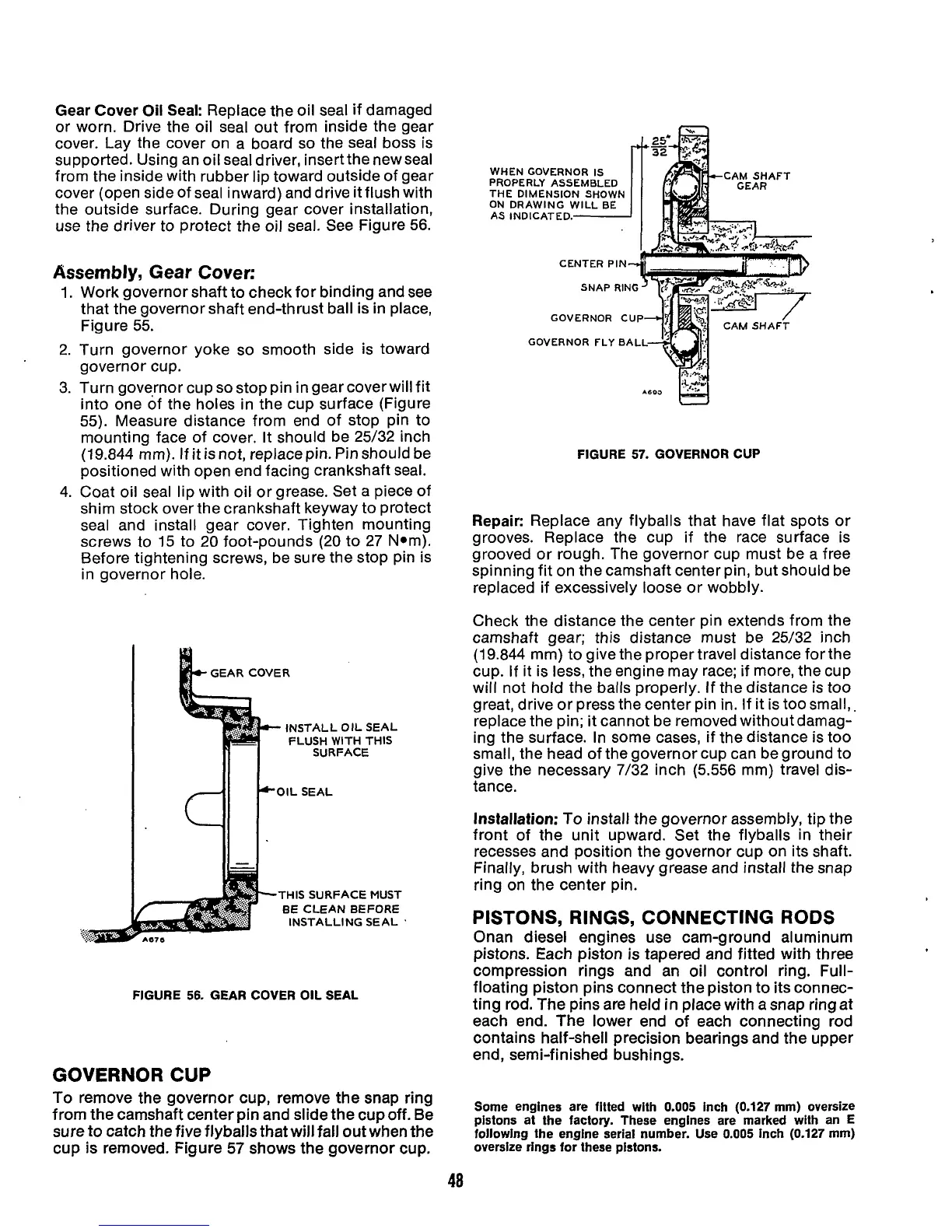

Gear Cover Oil Seal:

Replace the oil seal if damaged

or worn. Drive the oil seal out from inside the gear

cover. Lay the cover on a board

so

the seal boss is

supported. Using an oil seal driver, insertthe new seal

from the inside with rubber lip toward outside of gear

cover (open side of seal inward) and drive it flush with

the outside surface. During gear cover installation,

use the driver to protect the oil seal. See Figure 56.

Assembly, Gear Cover:

1. Work governor shaft to check for binding and see

that the governor shaft end-thrust ball is

in

place,

Figure 55.

2. Turn governor yoke

so

smooth side is toward

governor cup.

3.

Turn gove,rnor cup

so

stop pin in gear cover will fit

into one of the holes in the cup surface (Figure

55). Measure distance from end of stop pin to

mounting face of cover. It should be 25/32 inch

(19.844

mm). If it isnot, replace pin. Pin should be

positioned with open end facing crankshaft seal.

4. Coat oil seal lip with oil or grease. Set a piece of

shim stock over the crankshaft keyway to protect

seal and install gear cover. Tighten mounting

screws

to

15 to 20 foot-pounds (20 to 27 Nom).

Before tightening screws, be sure the stop pin is

in governor hole.

GEAR COVER

INSTALL OIL SEAL

FLUSH WITH THIS

SURFACE

'1

FOILSEAL

.. ,...

THIS SURFACE MUST

'.::$>

k..fl

BE CLEAN BEFORE

INSTALLING

SEAL

'

FIGURE

56.

GEAR COVER

OIL

SEAL

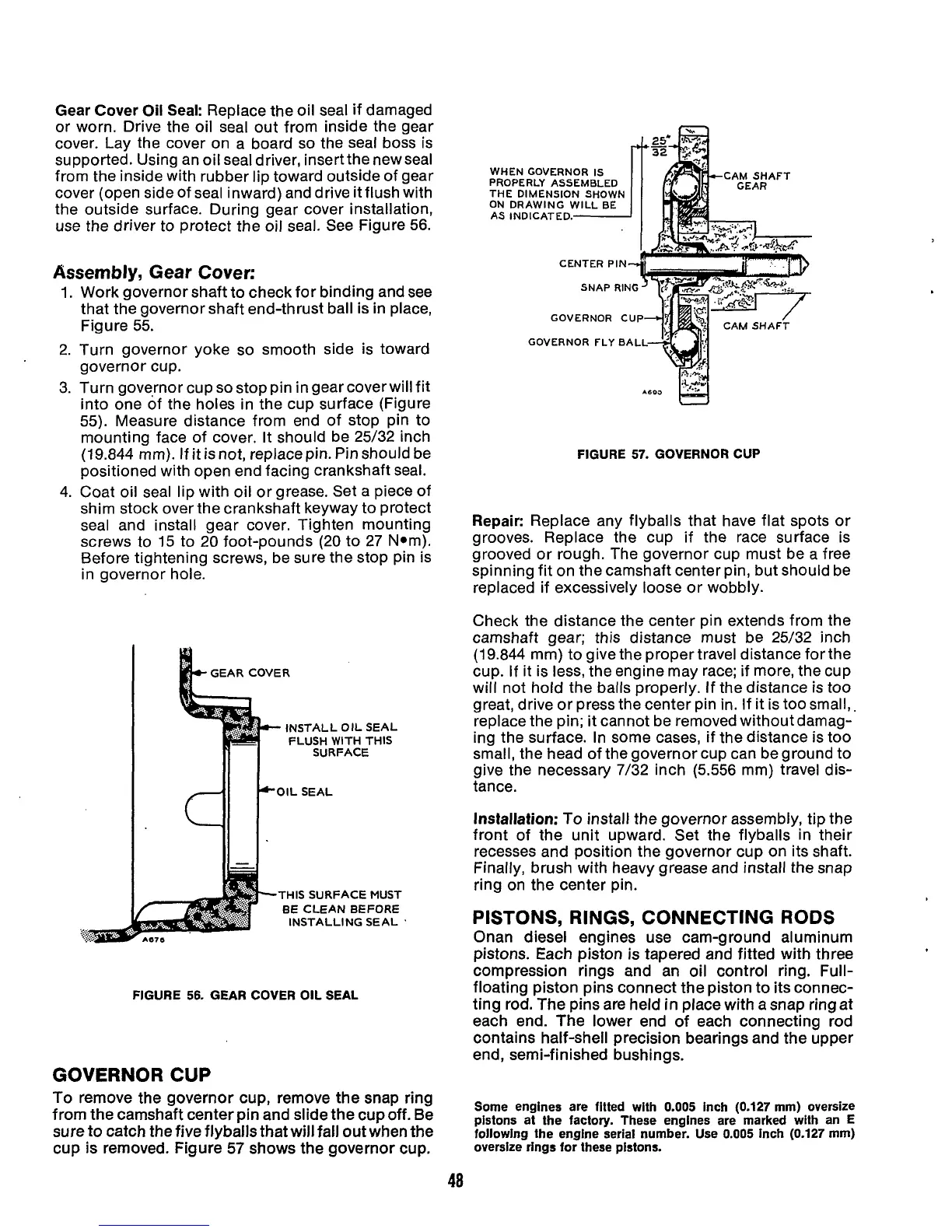

GOVERNOR

CUP

To

remove the governor cup, remove the snap ring

from the camshaft center

pin

and slide the cupoff. Be

sure to catch the five flyballs that will fall out when the

cup is removed. Figure

57

shows the governor cup.

WHEN GOVERNOR

IS

CAM

SHAFT

CENTER PIN

GOVERNOR CUP

GOVERNOR FLY

BAL

FIGURE

57.

GOVERNOR CUP

Repair:

Replace any flyballs that have flat spots or

grooves. Replace the cup if the race surface is

grooved or rough. The governor cup must be a free

spinning fit on the camshaft center pin, but should be

replaced if excessively loose or wobbly.

Check the distance the center pin extends from the

camshaft gear; this distance must be 25/32 inch

(19.844 mm) to give the propertravel distance for the

cup.

If

it is less, the engine may race; if more, the cup

will not hold the balls properly. If the distance is too

great, drive or press the center pin in. If it is too small,

replace the pin; it cannot be removed withoutdamag-

ing the surface. In some cases, if the distance is too

small, the head of the governor cup can be ground to

give the necessary 7/32 inch (5.556 mm) travel dis-

tance.

Installation:

To

install the governor assembly, tip the

front of the unit upward. Set the flyballs in their

recesses and position the governor cup on its shaft.

Finally, brush with heavy grease and install the snap

ring on the center pin.

PISTONS,

RINGS,

CONNECTING RODS

Onan diesel engines use cam-ground aluminum

pistons. Each piston is tapered and fitted with three

compression rings and an oil control ring. Full-

floating piston pins connect the piston to its connec-

ting rod. The pins are held

in

place with a snap ring at

each end. The lower end of each connecting rod

contains half-shell precision bearings and the upper

end

,

semi -f

i

n

ish ed bushings.

Some engines are fitted with 0.005 inch (0.127 mm) oversize

plstons

at

the factory. These engines are marked with an E

following the engine serial number. Use 0.005 inch (0.127 mm)

oversize rings for these pistons.

48

Loading...

Loading...