'

Removal and Disassembly

On 2-cylinder engines, the connecting rod and cap

are stamped for installation

in

the proper cylinder.

When removing piston assemblies, check the mark-

ing

so

each can be installed in the proper cylinder.

1.

Drain crankcase oil and remove oil base.

2. Remove cylinder heads.

3.

Before pushing pistons out, scrape carbon at top

,

of cylinder bore.

4. Remove cap from each connecting rod and push

assembly through top of cylinder bore. Replace

cap and bearing inserts in proper assembly.

5.

Using a ring expander, remove rings from each

pis ton.

6. Remove two retaining rings and push piston pin

from each piston.

Cylinders

The cylinder walls should be free of scratches, pitting

and scuffing. Check each with an inside reading

micrometer for out-of-round and wear. The bore

should measure between

3.4995

inches

(88.8873

mm)

and

3.5005

inches

(88.9127

mm) and be less than

0.001

inch

(0.0243

mm) out-of-round.

If necessary, rebore the cylinder

to

fit the next

available oversize piston. Pistons and rings are

available in

0.005

inch

(0.127

mm),

0.010

inch

(2.540

mm),

0.020

inch

(0.508

mm)

0.030

inch

(0.762

mm) and

0.040

inch

(1.016

mm) oversize. If the

cylinders do not need refinishing, remove any ex-

isting ridges from the top of the walls with a finestone.

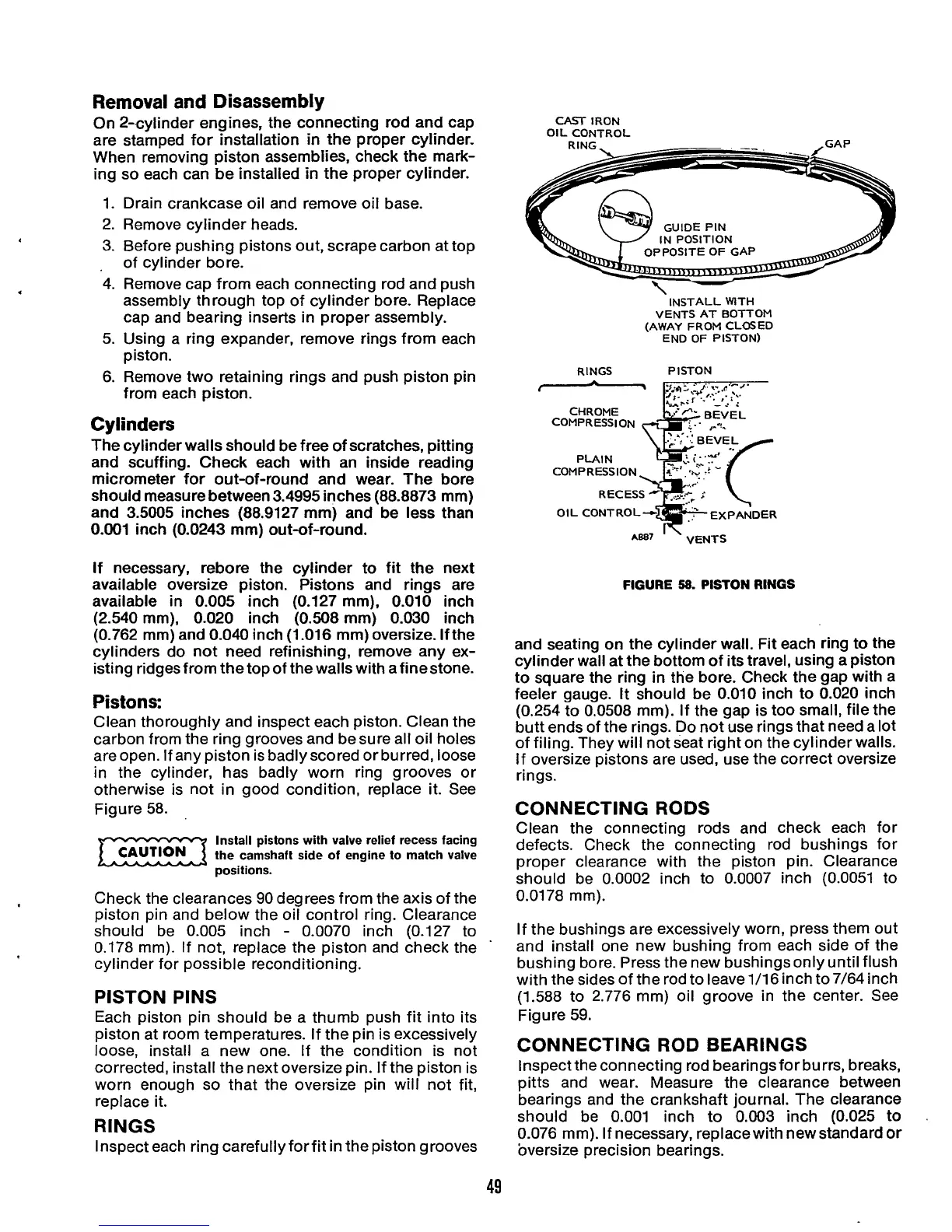

Pistons:

Clean thoroughly and inspect each piston. Clean the

carbon from the ring grooves and besure all oil holes

are open.

If

any piston

is

badly scored or burred, loose

in the cylinder, has badly worn ring grooves or

otherwise

is

not in good condition, replace it. See

Figure 58.

m

positions.

Check the clearances

90

degrees from the axis of the

piston pin and below the oil control ring. Clearance

should be

0.005

inch

-

0.0070 inch (0.127 to

0.178 mm).

If

not, replace the piston and check the

'

cylinder for possible reconditioning.

PISTON PINS

Each piston pin should be a thumb push fit into its

piston at room temperatures. If the pin is excessively

loose, install a new one. If the condition is not

corrected, install the next oversize pin. If the piston is

worn enough

so

that the oversize pin will not fit,

replace it.

RINGS

Inspect each ring carefullyforfit in the piston grooves

Install pistons with valve relief recess facing

the camshaft side of engine

to

match valve

CAUTION

~

.-

IN

POSITION

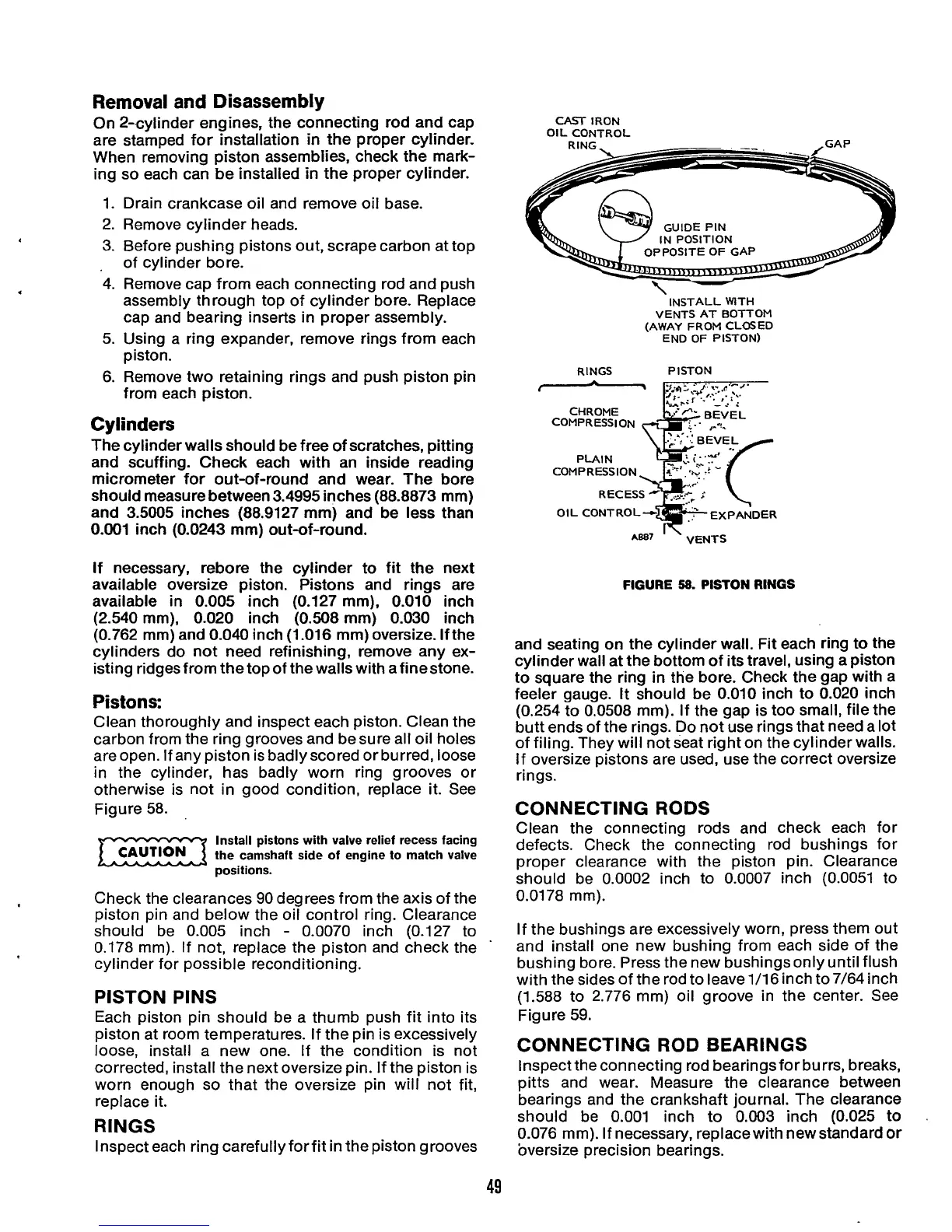

CAST

IRON

OIL CONTROL

INSTALL WlTH

VENTS AT BOTTOM

(AWAY

FROM

CLOSED

END

OF

PISTON)

RINGS PISTON

CHROME BEVEL

COMPRESSION

RECESS

-1

AB87

'

'

VENTS

FIGURE

58.

PISTON

RINGS

and seating on the cylinder wall. Fit each ring

to

the

cylinder wall at the bottom of its travel, using a piston

to square the ring

in

the bore. Check the gap with a

feeler gauge.

It

should be

0.010

inch to

0.020

inch

(0.254 to 0.0508 mm).

If

the gap is too small, file the

butt ends of the rings. Do not use rings that need a lot

of filing. They will not seat right on the cylinder walls.

If

oversize pistons are used, use the correct oversize

rings.

CONNECTING

RODS

Clean the connecting rods and check each for

defects. Check the connecting rod bushings for

proper clearance with the piston pin. Clearance

should be 0.0002 inch to 0.0007 inch

(0.0051

to

0.0178 mm).

If

the bushings are excessively worn, press them out

and install one new bushing from each side of the

bushing bore. Press the new bushings only until flush

with the sides of the rod to leave 1/16 inch to 7/64 inch

(1.588 to 2.776 mm) oil groove in the center. See

Figure

59.

CONNECTING

ROD

BEARINGS

Inspect the connecting rod bearingsfor burrs, breaks,

pitts and wear. Measure the clearance between

bearings and the crankshaft journal. The clearance

should be

0.001

inch to

0.003

inch

(0.025

to

0.076 mm).

If

necessary, replace with new standard

or

oversize precision bearings.

49

Loading...

Loading...