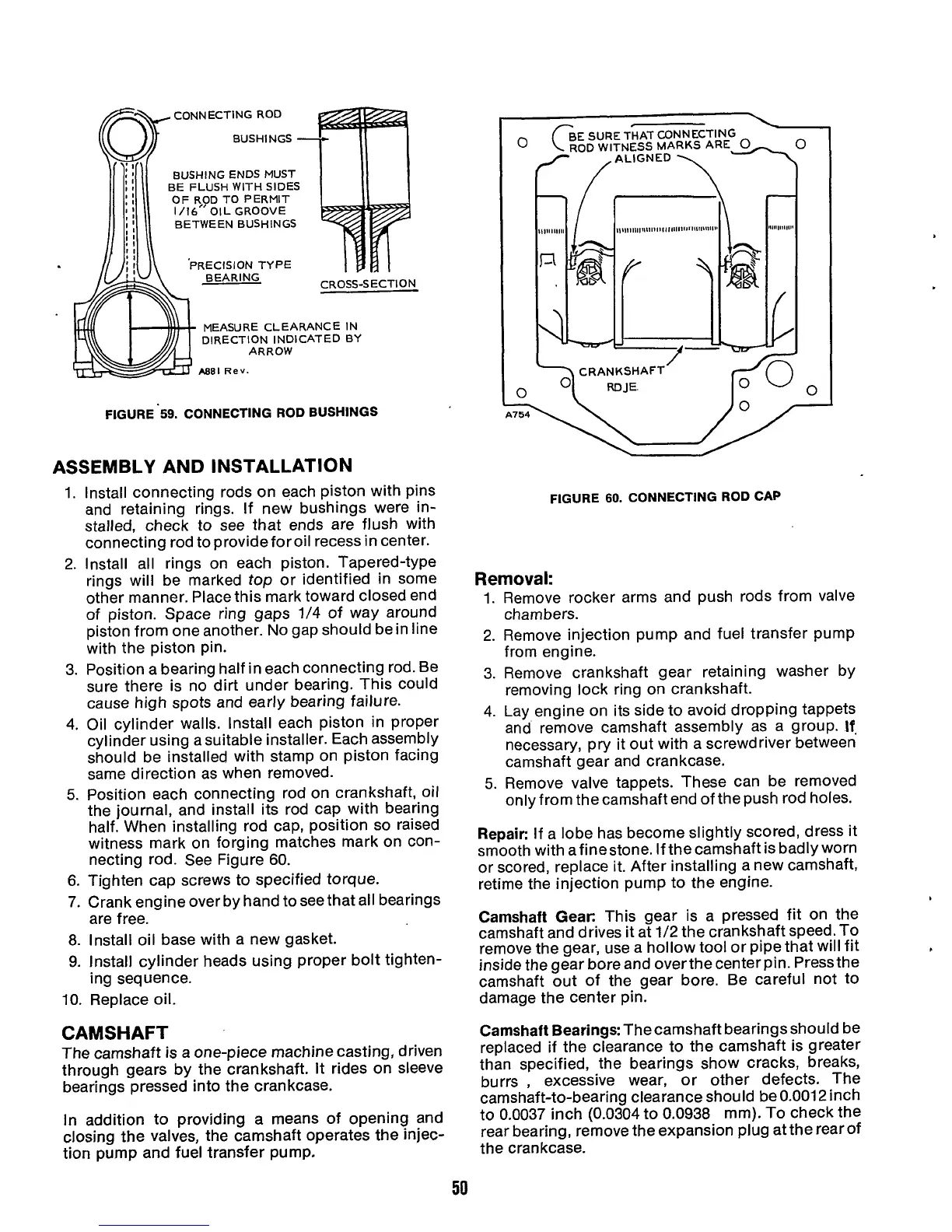

CONNECTING ROD

BUSHING ENDS

M

BE FLUSH WITH

S

OF

ROD TO PER

1/16”01L GROOVE

BETWEEN BUSHINGS

II

Iiil

F

’RECISION TYPE

BEARING

’

MEASURE CLEP

DIRECTION INDl

ARROW

A881

Rev.

rR

IC

LANCE

:ATED

3SS-S

ECTl ON

IN

BY

FIGURE

‘59.

CONNECTING

ROD

BUSHINGS

ASSEMBLY AND INSTALLATION

1.

2.

3.

4.

5.

6.

7.

8.

9.

Install connecting rods on each piston with pins

and retaining rings. If new bushings were in-

stalled, check to see that ends are flush with

connecting rod to provide for oil recess

in

center.

Install all

rings on each piston. Tapered-type

rings will be marked

top

or identified in some

other manner. Place this mark toward closed end

of piston. Space ring gaps

1/4

of way around

piston from one another.

No

gap should be in line

with the piston pin.

Position a bearing half

in

each connecting rod. Be

sure there is no dirt under bearing. This could

cause

high

spots and early bearing failure.

Oil cylinder walls. Install each piston in proper

cylinder using a suitable installer. Each assembly

should be installed with stamp on piston facing

same direction as when removed.

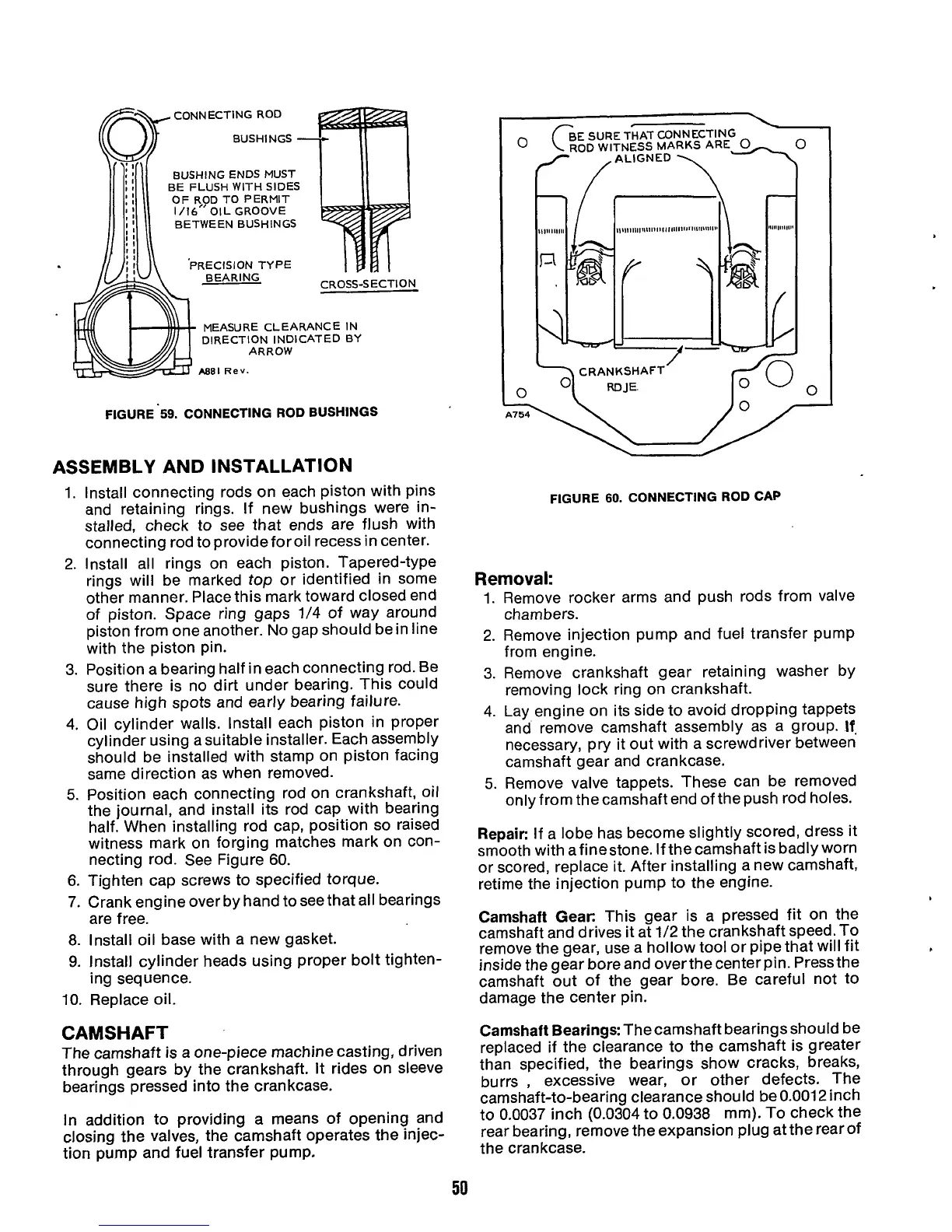

Position each connecting rod on crankshaft, oil

the journal, and install its rod cap with bearing

half. When installing rod cap, position

so

raised

witness mark on forging matches mark on con-

necting rod. See Figure

60.

Tighten cap screws to specified torque.

Crank engine over by hand to see that all bearings

are free.

Install oil base with a new gasket.

Install cylinder heads using proper bolt tighten-

ing sequence.

10.

Replace oil.

CAMSHAFT

The camshaft is a one-piece machine casting, driven

through gears by the crankshaft.

It

rides on sleeve

bearings pressed into the crankcase.

In

addition to providing

a

means of opening and

closing the valves, the camshaft operates the injec-

tion pump and fuel transfer pump.

FIGURE 60. CONNECTING

ROD

CAP

Removal:

1.

Remove rocker arms and push rods from valve

chambers.

2.

Remove injection pump and fuel transfer pump

from engine.

3.

Remove crankshaft gear retaining washer by

removing lock ring on crankshaft.

4. Lay engine on its side to avoid dropping tappets

and remove camshaft assembly as a group.

If.

necessary, pry it out with a screwdriver between

camshaft gear and crankcase.

5.

Remove valve tappets. These can be removed

only from the camshaft end of the push rod holes.

Repair:

If a lobe has become slightly scored, dress it

smooth with afinestone. If the camshaft is badly worn

or scored, replace it. After installing a new camshaft,

retime the injection pump to the engine.

Camshaft Gear:

This gear is a pressed fit on the

camshaft and drives it at

1/2

the crankshaft speed.To

remove the gear, use a hollow tool or pipe that will fit

inside the gear bore and over the center pin. Press the

camshaft out of the gear bore. Be careful not to

damage the center pin.

Camshaft Bearings:

Thecamshaft bearings should be

replaced if the clearance to the camshaft is greater

than specified, the bearings show cracks, breaks,

burrs

,

excessive wear, or other defects. The

camshaft-to-bearing clearance should be

0.001

2

inch

to

0.0037

inch (0.0304 to

0.0938

mm).

To

check the

rear bearing, remove the expansion plug at the rear of

the crankcase.

50

Loading...

Loading...