4.

Mount and secure rear bearing plate.

5.

Heat timing gear on an electric burner

or

oven to

about 350"

F

(175°C). Install key on crankshaft,

then drivegear into place. Install retaining washer

and lock ring.

CRANKCASE

If the crankcase requires replacement, a new set of

injection pump shims will be furnished with the new

crankcase. These must be used and, in addition, the

injection pump must be retimed to the engine.

6-

Check crankshaft end play. Use enough rear

bearing plate shims and gaskets

to

provide 0.010

inch

(0*254

mm)

to

0'015

inch

(0*381

mm)

end

'lay'

If

gaskets

Of

more

than

0'01

inch

steel

shim

Of

proper

thickness

and

a

thin

gasket

on each side

of

shim. This avoids excessive

gasket compression and maintains bolt torque.

BREAK-IN

PERIOD

Whenever new rings or pistons are installed or the

cylinder refinished, the engine must be run-in before

regular operation can be resumed. Run theengine for

load, and 2 to 3 hours at 2/3 load. Regular operation

can

then

be

Avoid

light

load

operation

during the following several hours for best ring

(0.381

mm)

total

thickness

are

required,

use

a

15

to 20 minutes at no load, about 30 minutes at 1/3

7.

Install

piston assemblies.

seating to prevent oil consumption.

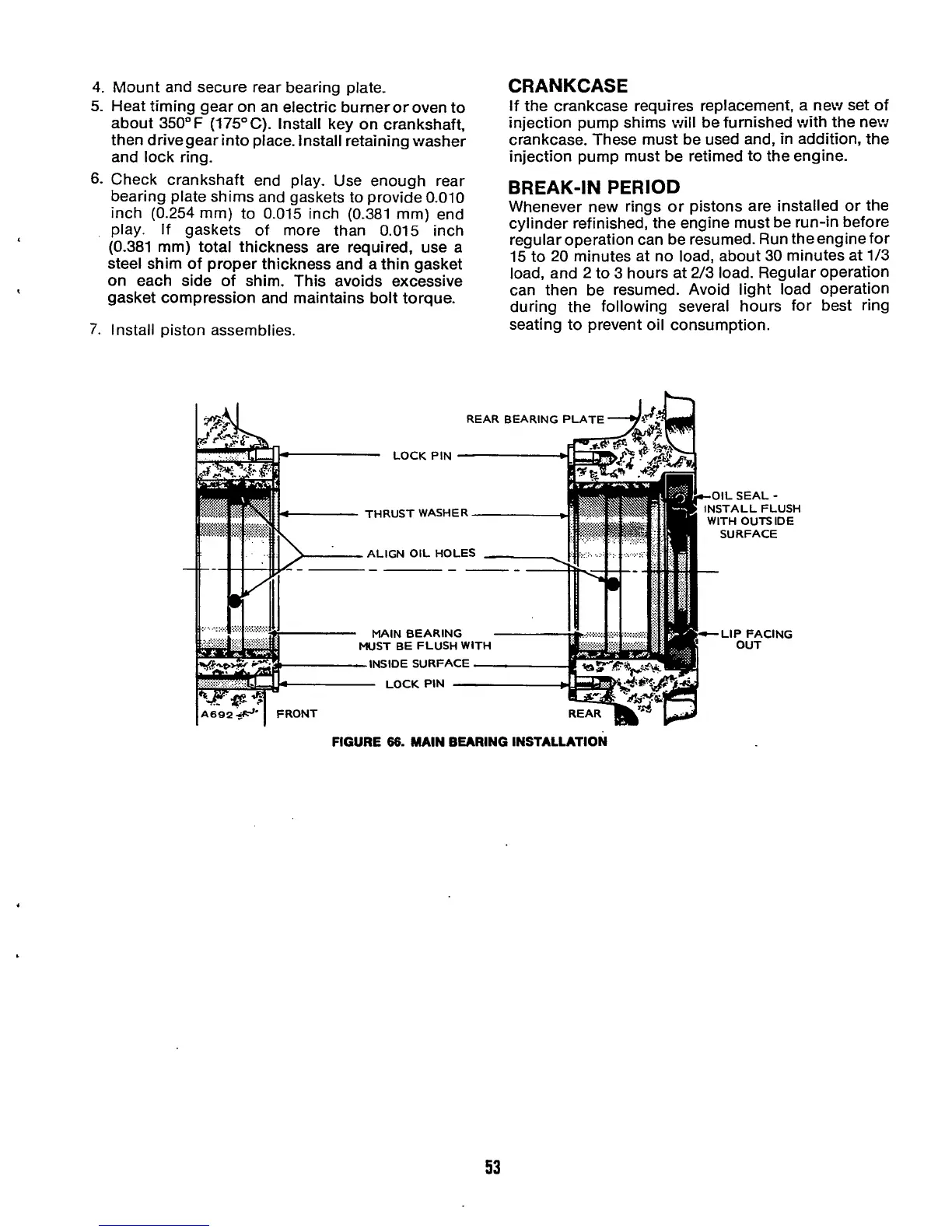

USH

DE

THRUST

WASHER

ALIGN

OIL

HOLES

MAIN BEARING

LIP

FACING

MUST

BE

FLUSH

WITH

FIGURE

66.

MAIN BEARING INSTALLATION

53

Loading...

Loading...