Reassembly and Installation (Walbro)

1.

Install needle valve and seat, main jet and fioat

assembly. Make sure that float pivot pin is properly

placed and that float moves freely without binding.

2.

Gently push float tang down until needle

just

seats.

(Figure

4).

Measure float level; adjust

if

necessary.

Release float tang and measure float drop; adjust if

necessary. When checking float level and drop,

measure

to

float body, not seam.

3.

Position gasket on carburetor and attach carburetor

sections together with screws.

4.

Slide in throttle shaft and install plate using new

screws. Before tightening the screws, the plate must

be centered in the bore. To do

so,

back

off

the

throttle stop screw as necessary and completely

close the throttle lever. Seat the plate by tapping

with a small screwdriver, then tighten screws. Install

the choke shaft and plate in the same manner.

5.

Install idle adjustment screw, throttle stop screw,

and main fuel adjustment needle.

6.

Mount carburetor on intake manifold and install

assembly on engine.

7.

Mount air cleaner assembly. Connect air intake

hose, breather hose, fuel line, vacuum line, and

throttle linkage.

8.

Adjust carburetor and governor according

to

direc-

tions given in this section.

Reassembly and Installation

(Nikki limited idle adjustment)

1.

Install needle valve, main jet, and float assembly.

Make sure float pivot pin is properly placed and floa/

moves freely without binding.

2.

Turn carburetor on its side and measure float level

(Figure

4).

Adjust float level only

if

necessary.

Measure float drop (the distance from the top of

carburetor body

to

top of float). Adjust only

if

necessary.

3.

Position gasket on lower carburetor section and

install upper carburetor section.

4.

Install idle adjustment screw, throttle stop screw,

and fixed main jet plug.

?

5.

Mount' carburetor on intake manifold and install

?

assembly on engine.

6.

Mount' air cleaner assembly. Connect air intake

hose, breather hose, fuel line, vacuum line, and

throttle linkage.

7.

Adjust carburetor and governor according

to

direc-

tions given in this section.

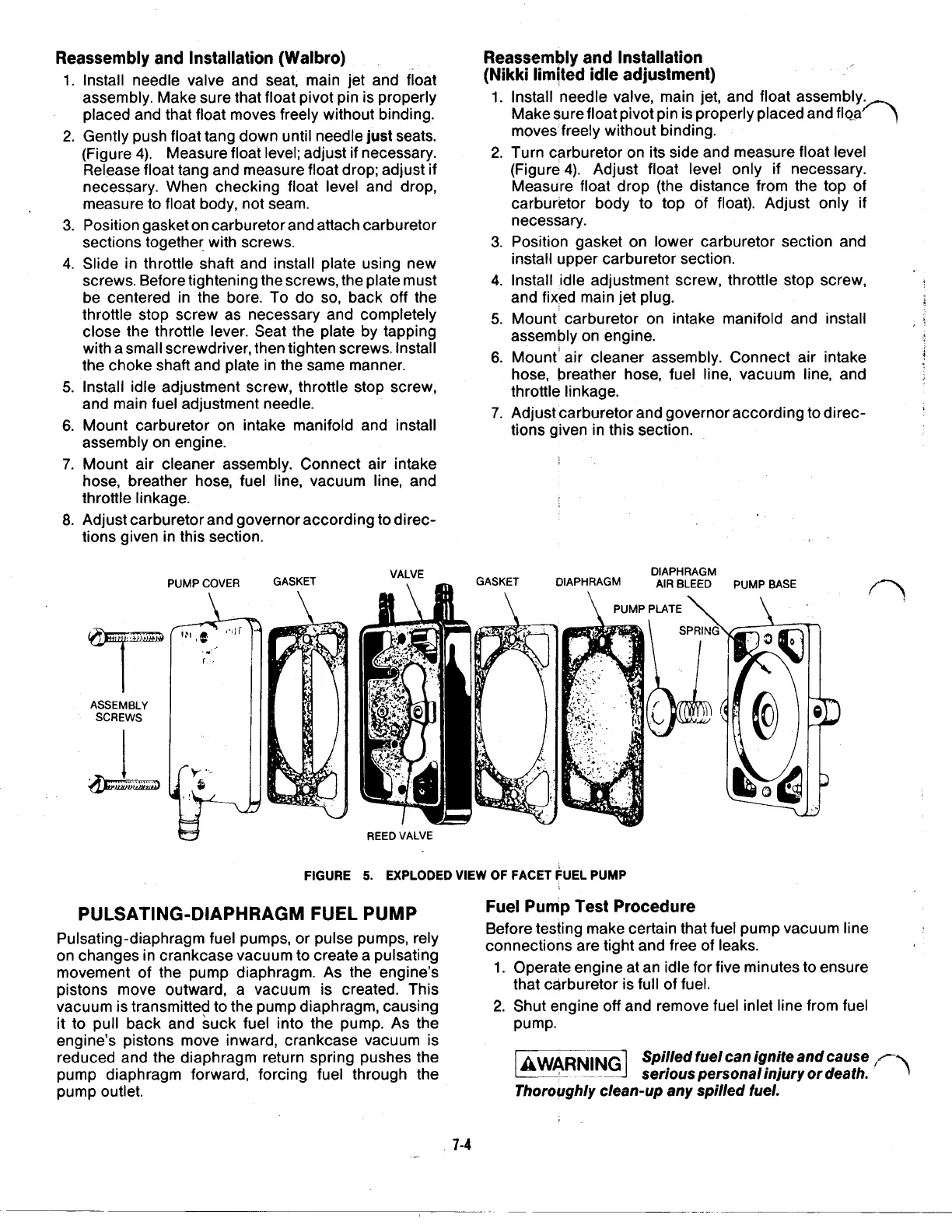

ASSEMBLY

SCREWS

VALVE DIAPHRAGM

REED VALVE

FIGURE

5.

EXPLODED

VIEW

OF

FACET

FUEL

PUMP

PULSATING-DIAPHRAGM FUEL PUMP

Pulsating-diaphragm fuel pumps, or pulse pumps, rely

on changes in crankcase vacuum to create a pulsating

movement of the pump diaphragm. As the engine's

pistons move outward, a vacuum is created. This

vacuum is transmitted

to

the pump diaphragm, causing

it

to

pull back and suck fuel into the pump. As the

engine's pistons move inward, crankcase vacuum is

reduced and the diaphragm return spring pushes the

pump diaphragm forward, forcing fuel through the

pump outlet.

PUMP BASE

\

Fuel Pump Test Procedure

Before testing make certain that fuel pump vacuum line

connections are tight and free of leaks.

1.

Operate engine at an idle for five minutes

to

ensure

2.

Shut engine

off

and remove fuel inlet line from fuel

that carburetor is full of fuel.

pump.

WARNING

WARNING

Spilled fuel can ignite and cause

serious personal injury or death.

Thoroughly clean-up any spilled fuel.

Loading...

Loading...