18

BELTS ADJUSTMENT:

WARNING

A loosened belt may slip and get worn quickly, a too tightened belt may wear out bearings.

• Check for belt condition, cracks and wear. Replace if necessary.

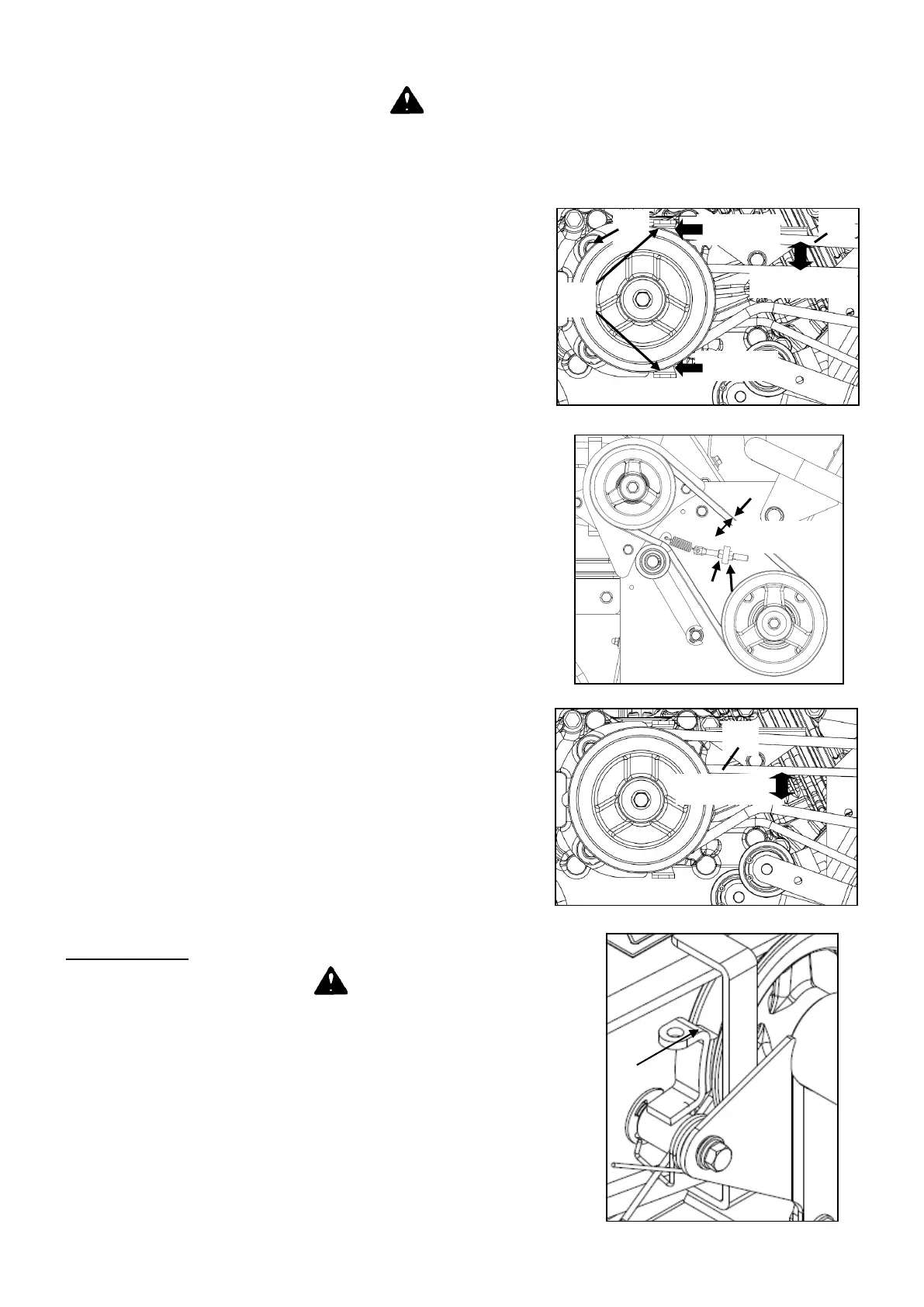

Belt from engine to counter shaft

• Stop engine and disconnect sparking cover, clutch the blade.

• Unscrew the three bolts of the shield to reach the belts.

• Push the belt with a finger on (A, Figure 22) the belt must

move from 10 to 12 mm. If the belt does not move accordingly,

perform “tension wire” again.

• Check that the belt guides (B, Figure 22) are close 3 or 4 mm

from the tighten belt.

• If it is necessary, adjust the belt guides as follow : unscrew

bolt (C, Figure 22) and adjust belt guides as required and

screw the bolt again.

• Fit the belt cover with the three bolts.

Belt from the counter shaft to the flails

• Stop engine and disconnect sparking cover.

• Unscrew the 2 bolts of the shield to reach the belt.

• Push the belt with a finger on (F, Figure 23) the belt must move

from 3 to 5 mm. If the belt does not move accordingly, adjust with

screws (A, Figure 23) & (B, Figure 23)

• Fit the belt cover with the two bolts.

Belt transmission adjustment

• Stop engine and disconnect sparking cover, clutch the blade.

• Unscrew the three bolts of the shield to reach the belts.

• Push the belt with a finger on (A, Figure 24) the belt must

move from 12 to 14 mm. If the belt does not move accordingly,

perform “tension wire” again.

• Fit the belt cover with the three bolts.

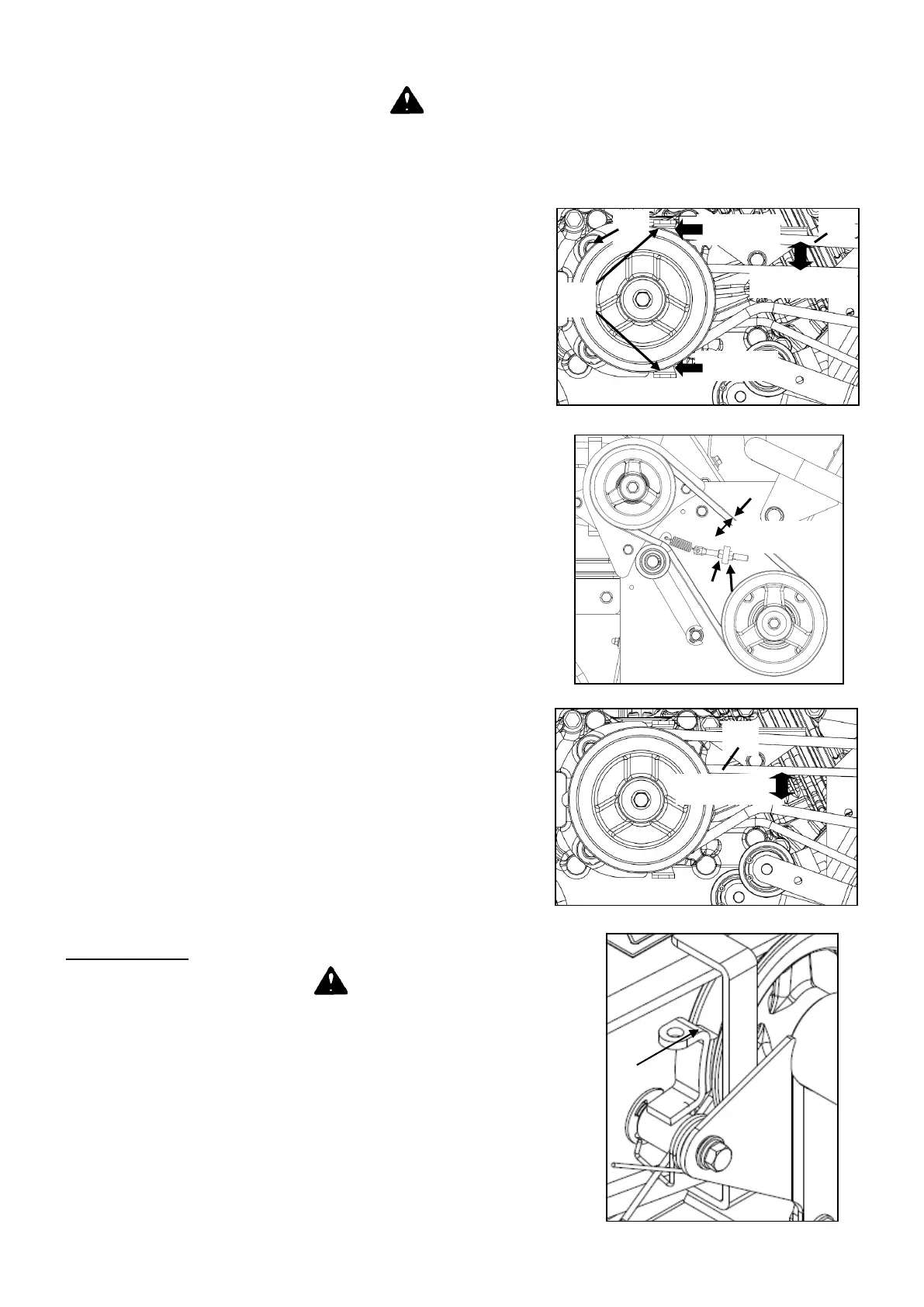

BLADE BRAKE :

WARNING

Check the blade brake every month (1, Figure 25), check the time for

the blade to stop when blade clutch lever is released. If more than 7

seconds are necessary for the blade to stop, ask your dealer

immediately to check the blade brake system.

Loading...

Loading...