OREC SF600/600D

MAINTENANCE OPERATIONS TO BE CARRIED OUT BY THE USER

DANGER

BEFORE perform any maintenance operation on the machine, cut off the engine, and remove the spark wire from

the sparking plug

If maintenance operation is not realized, damages can occur to the machine and personal injuries to the user and/or

spectators. These damages and injuries will not be covered by the warranty.

• Daily maintenance will be performed by the user.

• Maintenance operations for first 20 hours, 100 and 300 should be realized by the dealer.

• Ask your dealer to check the machine if you meet some problems.

DAILY MAINTENANCE, BEFORE START WORK

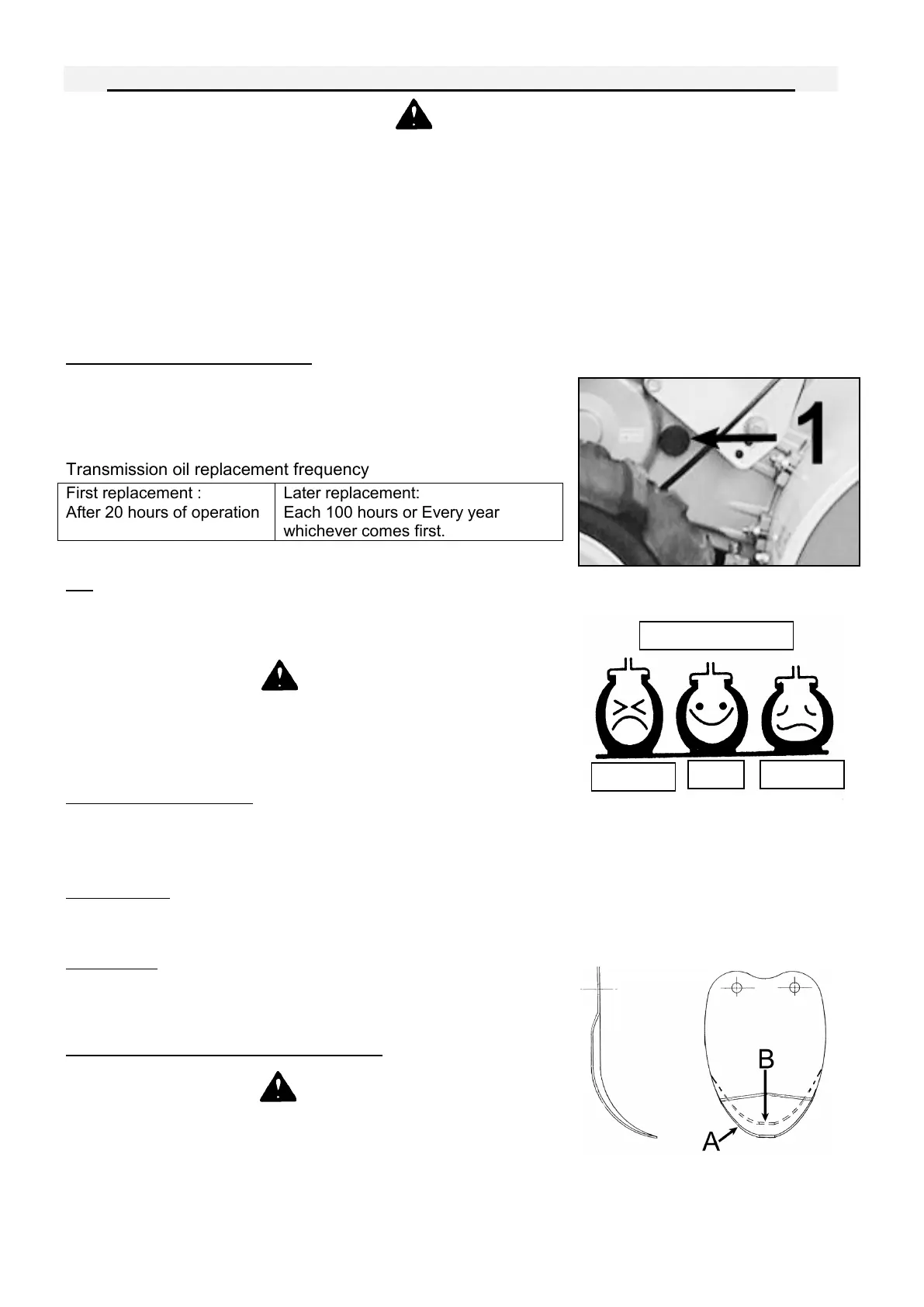

Transmission oil level : check by the plug (1 Figure 13). Oil level should appear

in the hole. Check only engine stopped since ten minutes on a flat level surface.

• Use only good quality gear oil “SAE 90” or “API GL-5”. Oil quantity : 3.00L

•

Check that there is no leaks

Transmission oil replacement frequency

Fuel

Check tank level is full before start to work. Check that tank plug is fully closed, and check for leaks. Use only a good

quality unleaded gasoline.

DANGER

Check fuel tank is closed, wipe spillages fuel before start the machine.

Check there is no fire, electric sparks, and cigarettes near the machine

when refueling.

Clean for flammable materials

Clean the machine from flammable materials, grass, woods which can be burnt on hot surfaces of the machine, especially

around the engine and the exhaust silencer.

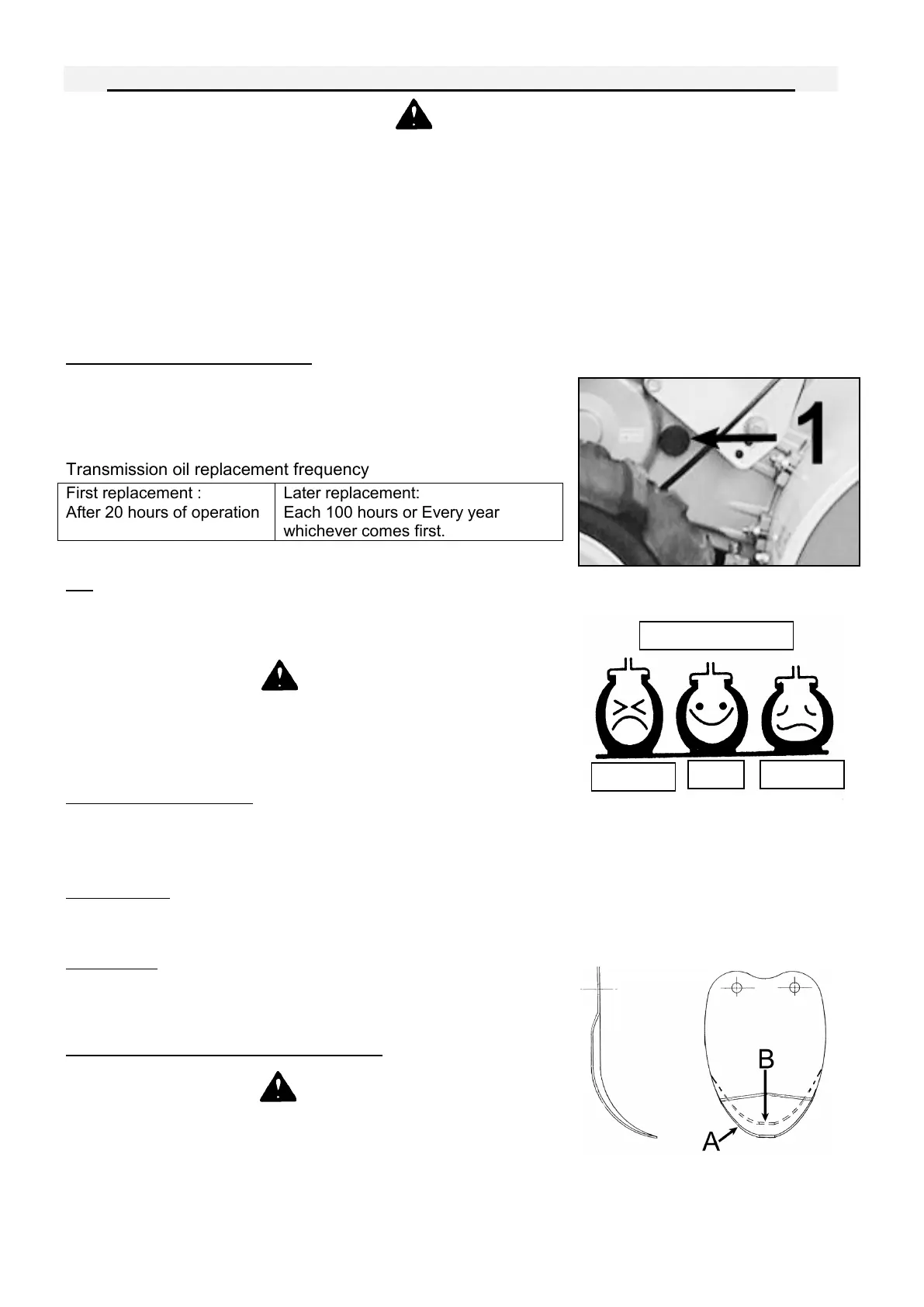

Tires (Figure 14)

Check tires are not cut, cracked or worn.

Check tires pressure : 1,2 bar.

Safety stickers

Check safety stickers are sticked at their place.

Replace them if they are worn and damage.

State of the working tool blade(SF600)(figure 15-1)

CAUTION

Blades can cut hands or fingers; always wear protective gloves when

holding blades.

• Check that rotary blades are in good condition, change worn or damage

blade if the blade is worn more than (20 mm) the point B figure 15-1,

comparing to a new blade (A, figure15-1).

• Changing the blade : Unscrew the to bolts and nuts of the blade on the

shaft.

After 20 hours of operation

Each 100 hours or Every year

figure 15-1

Loading...

Loading...