OREC SF600/600D

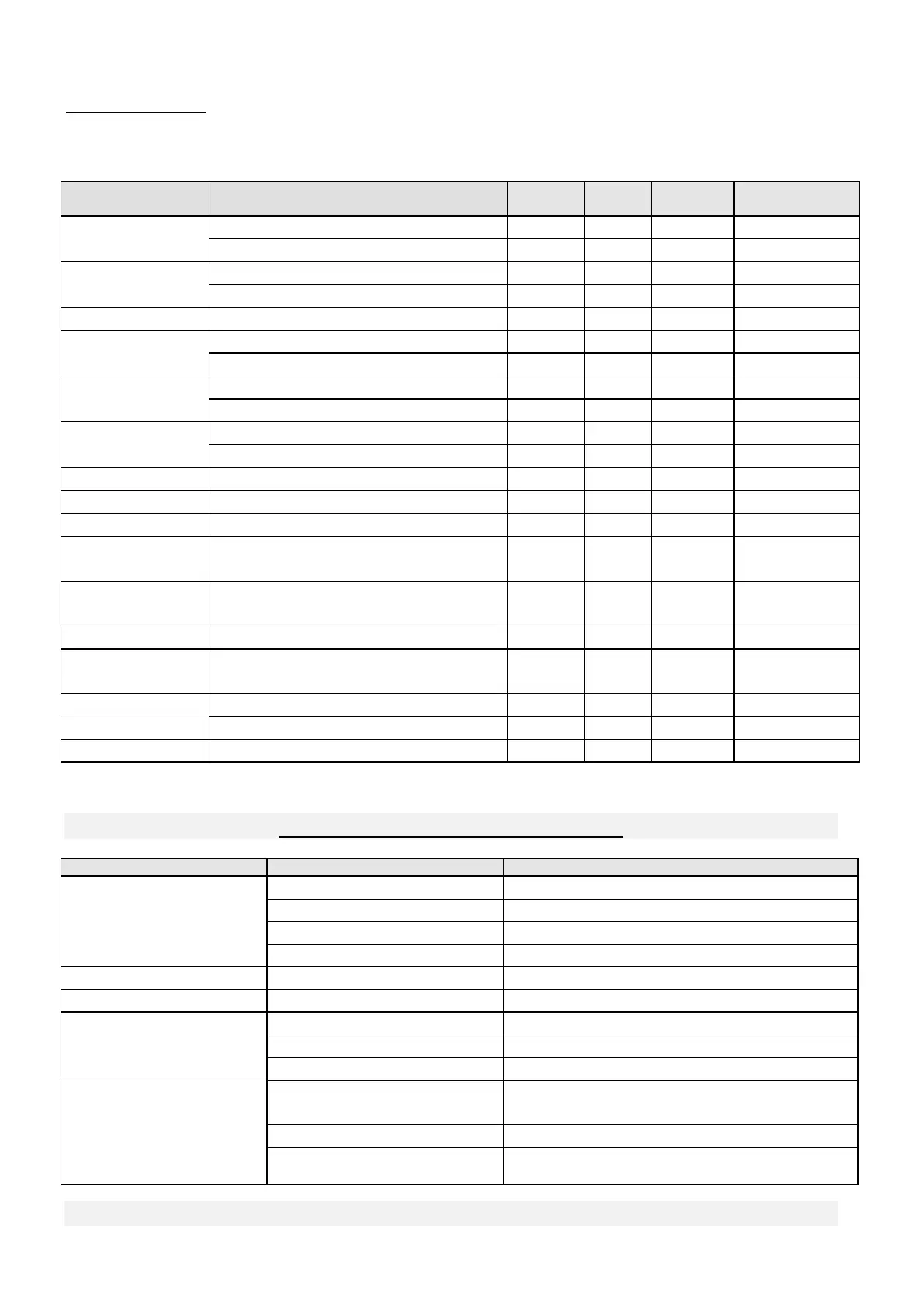

Maintenance chart

Ask your dealer to realize this operation needing special tools and knowledge.

⊕ Inspection to realize by the owners before starting the engine

⊗ Inspection to realize by the owners after starting the engine

Every 300 hours

every year

Clean the machine from flammables materials

check machine do not move when lever is on “N”

Check travel lever goes on “N” when applying brake

Check efficiency of the brake

Check travel lever goes on “N” when applying brake

Check for rust, and cracks

Check they are in place and in good condition

Guards & shields Check they are bolted in their place and in good

⊕

Tank and fuel hoses Check for leaks and good condition

⊕

tines Check they are bolted in their place and in good

⊕

Main clutch control lever

Check the adjustment of the wire

Check they tensioned and in good condition

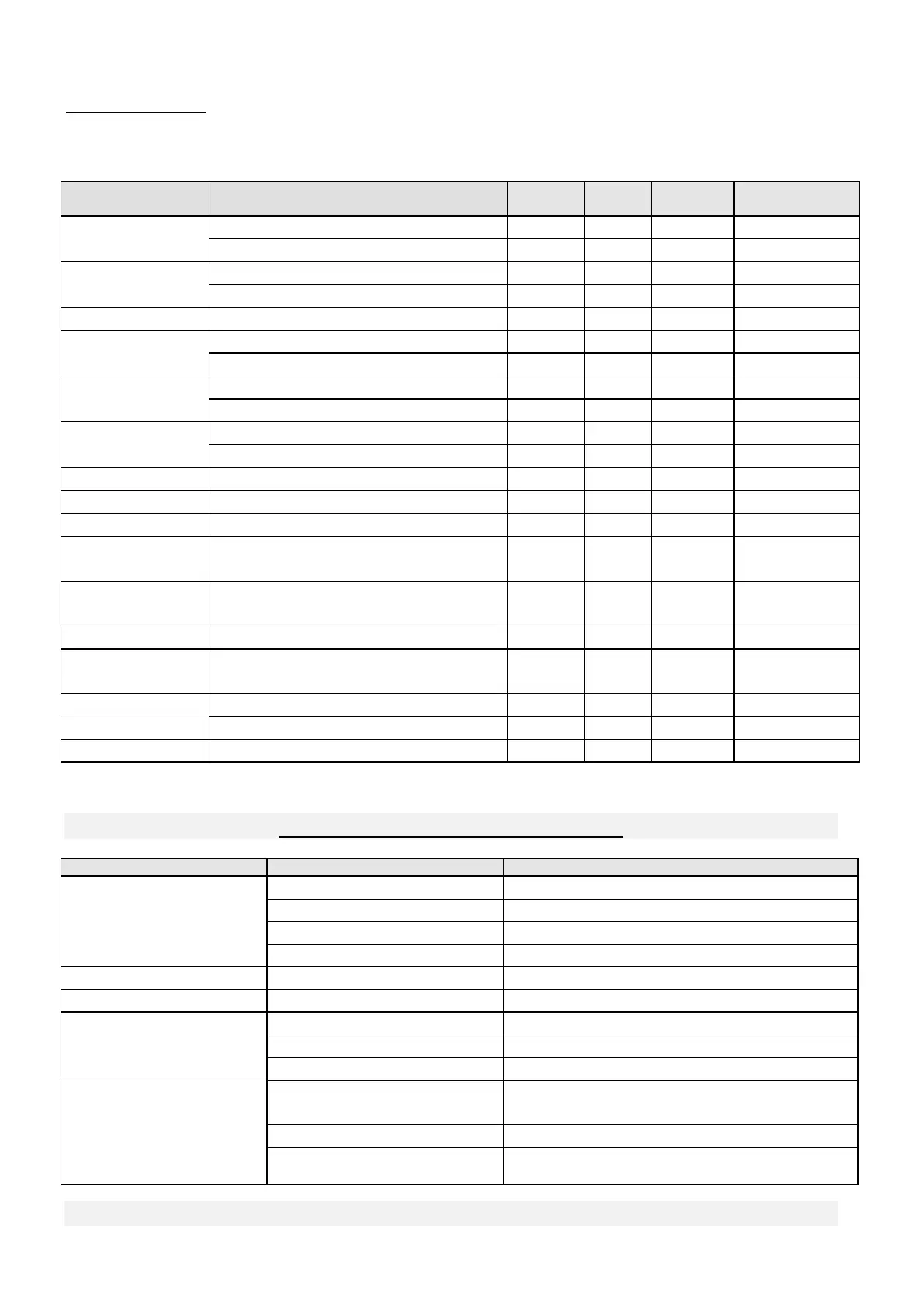

BREAKDOWNS AND SOLUTIONS

Load or replace the battery

Safety switches are working

Check brakes, blade clutch and seat and travel lever

The machine does not travel

The machine does not stop

Travel lever is not on « N »

Move the travel lever to « N »

main clutch lever is not engage

Engine rotation is not good

The rotor does not rotate

Chain,Sprocket, Gear is damaged

Cannot use because of clay or ground is too hard. Turn the

soil by other machine in advance.

Easy Anchor is worn or dropped. Cultivate too deep

Cannot cultivate completely

Change all tine for new one.

Easy Anchor is worn .

Loading...

Loading...