OREC SF600/600D

Diff lock wire tension

If the diff lock does not engage when you operate the control :

- Increase the wire tension. (Figure 18) Unscrew the nut A and screw the nut B to

the top of the machine. When the adjustment has been performed, screw again

the nut A.

If the diff lock does not disengage when you operate the control :

- Decrease the wire tension. Unscrew the nut B and screw the nut B to the low of

the machine. When the adjustment has been performed, screw again the nut A.

Lubrication

Lubricate with light oil (engine oil) following points :

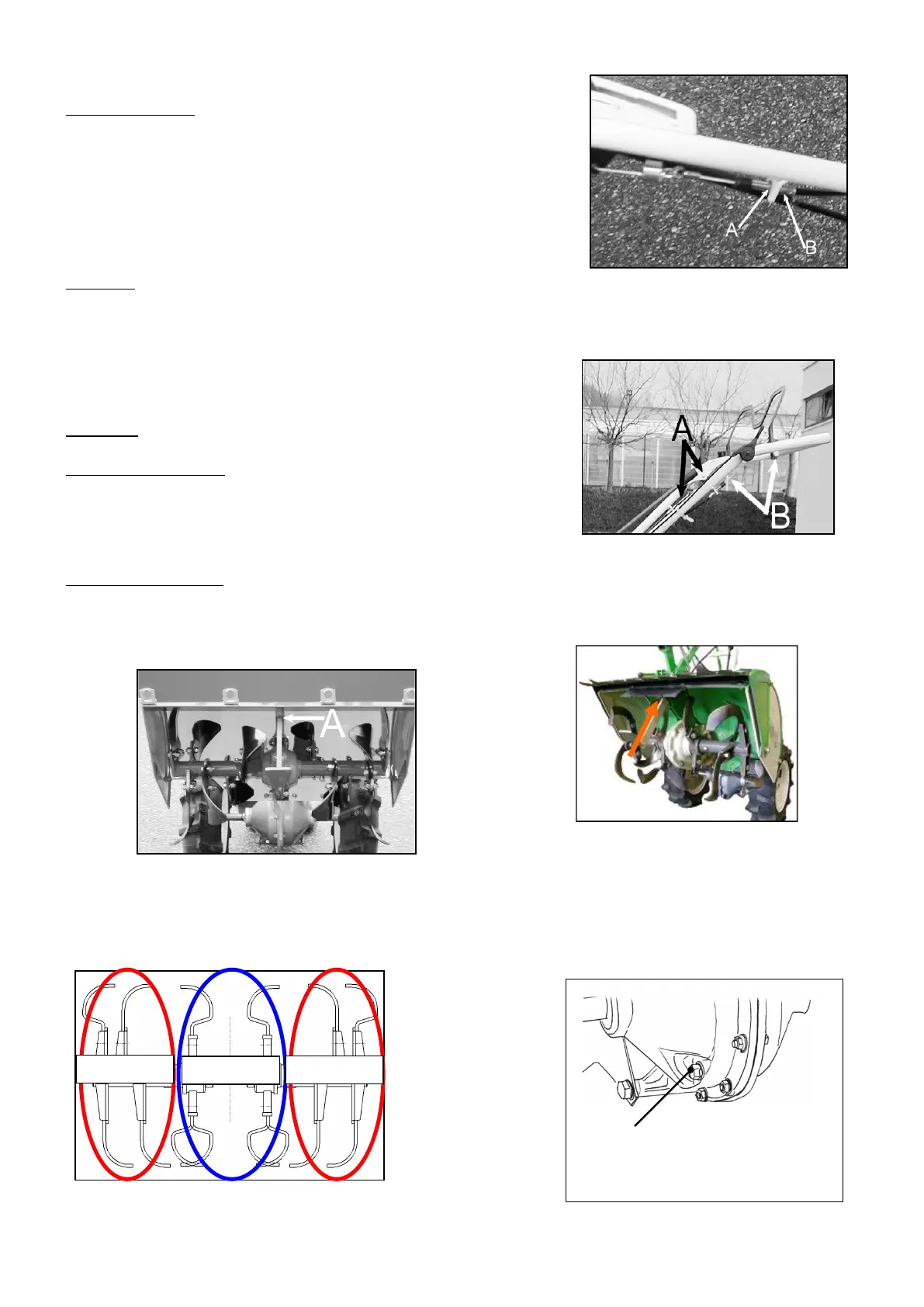

• Wires and control lever axles (A & B, Figure 19).

• Stand (A, Figure 20-1(SF600), 20-2(SF600D)).

• On the gear box, the diff lock lever and the speed lever.

• Tension belt lever under the belt case.

EVERY YEAR

Draining the transmission

On a level surface, put a tank under the transmission case and unscrew the plug

(A, Figure 21) and let the oil drop. Screw the plug again and add oil by the plug

(1, Figure 13) until the level is up to the plug hole.

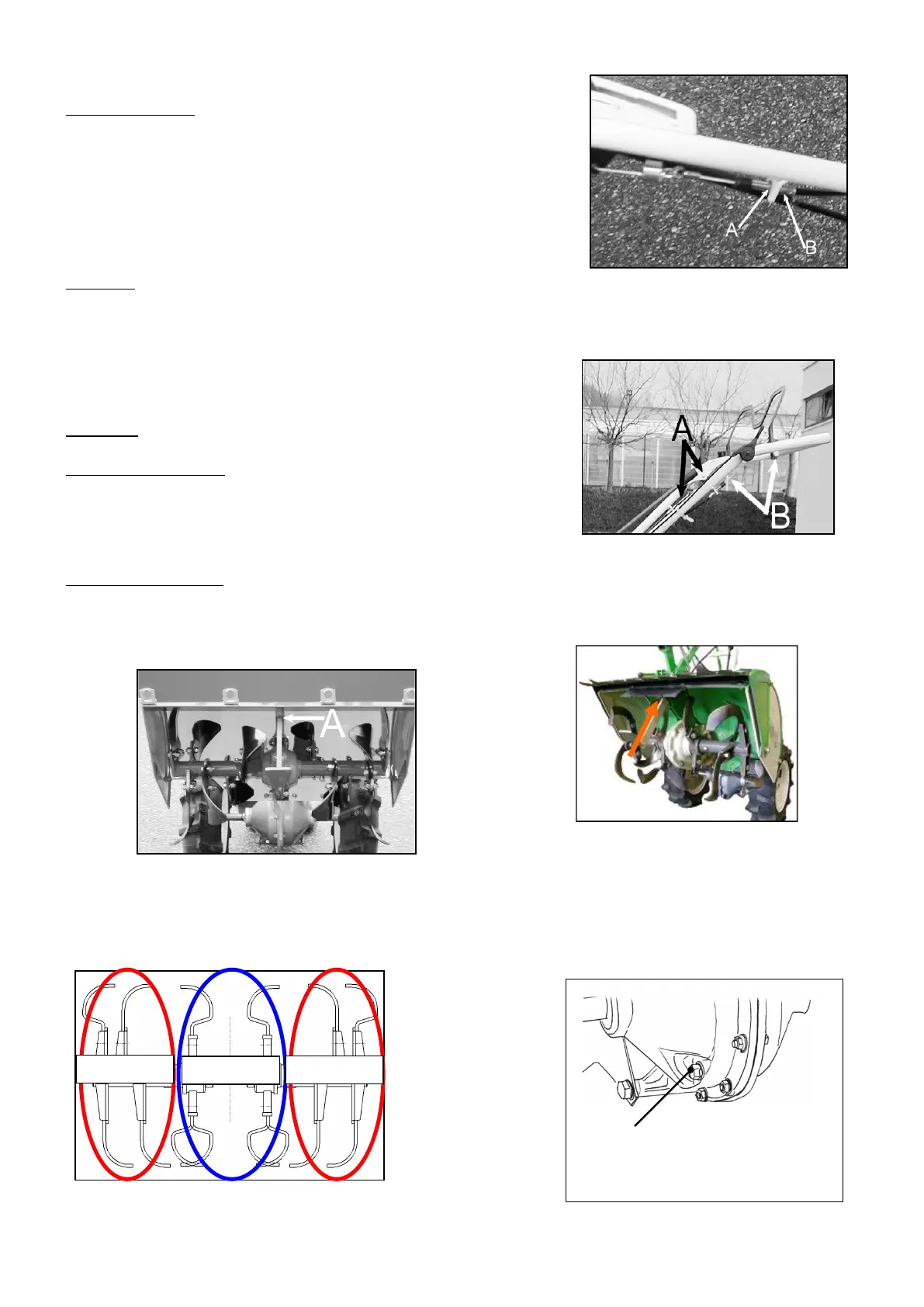

Blade position(Figure 22)

Blade rotates forward and reverses at same time.

Make sure if the blades are installed correctly.

Figure 19

Figure 20-2

Figure 22

(A) Drain plug

Figure 21

Loading...

Loading...