OREC SF600/600D

• Screw a new blade and check the screwing torque with the chart at the end

of this manual.

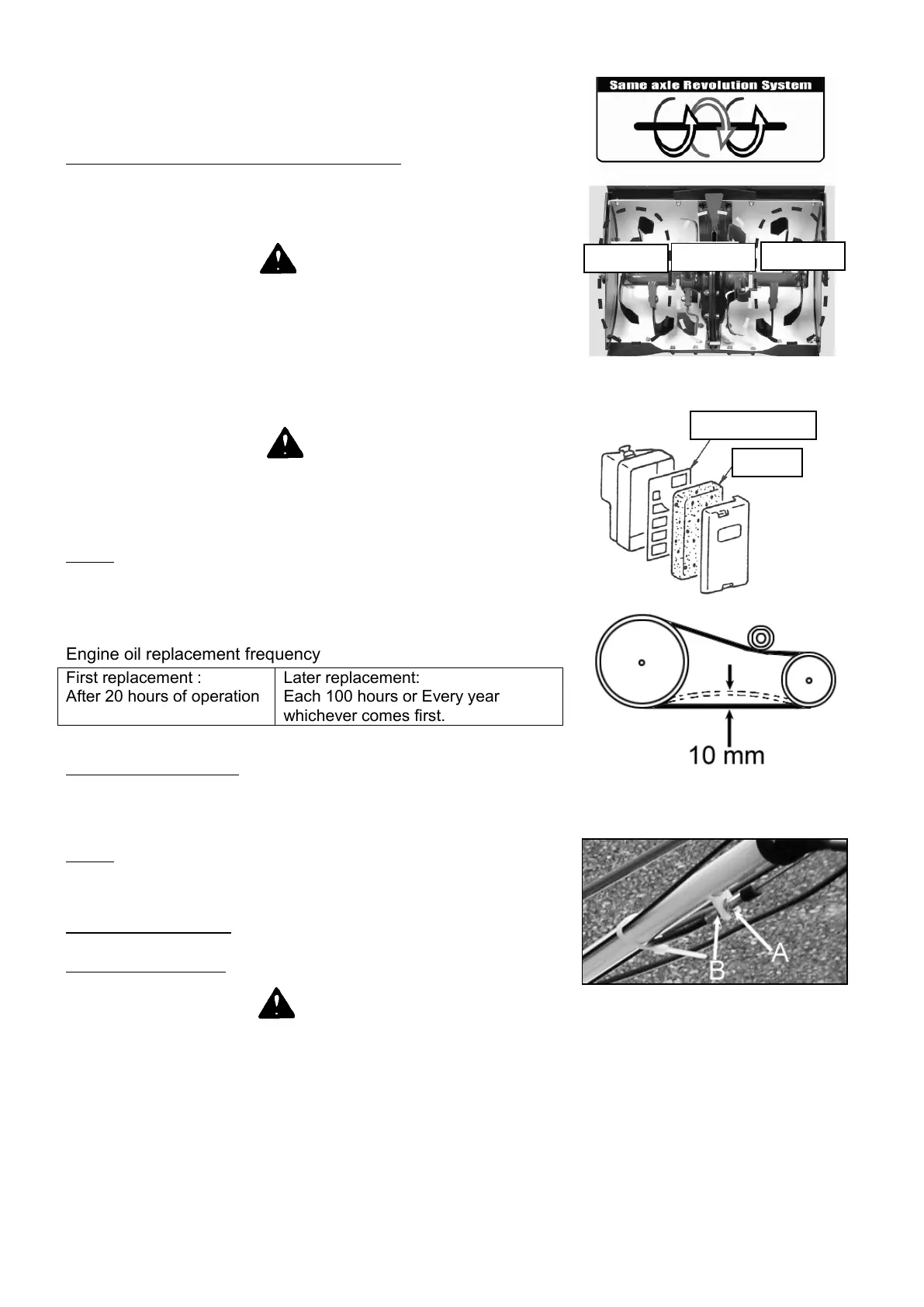

State of the working tool blade (SF600D)(Figure 15-2)

Center section : Up cut

Side section : Down cut

*Dual-Action cutting system makes for finer tilling

CAUTION

Blades can cut hands or fingers; always wear protective gloves when

holding blades.

• Check that rotary blades are in good condition, change worn or damage

blade if the blade is worn

• Changing the blade : Unscrew the to bolts and nuts of the blade on the shaft.

• Screw a new blade and check the screwing torque with the chart at the end

of this manual.

CAUTION

Only use original genuine OREC parts. Other parts may be dangerous for

your health and for the bystanders and the machine. If some vibration occur.

If you feel vibrations in the handlebar, check the blade. Vibrations may cause

loosening of the bolt and nuts and may crack the steel of the machine.

Engine

Refer to engine manual delivered with the machine.

Engine Oil Type : SAE10W30 or API SL class

Engine Oil Quantity : 0.58L

Engine oil replacement frequency

Tightening of bolts and nuts

Check the screwing torque with the chart at the end of this manual.

Vibration may loose bolts, nuts and screws.

Air filter

Check the air filter from dust and debris. Clean the foam with water and soap.

Dry it without squeezing it. Apply air filter oil before mounting.

MAINTENANCE EVERY MONTH

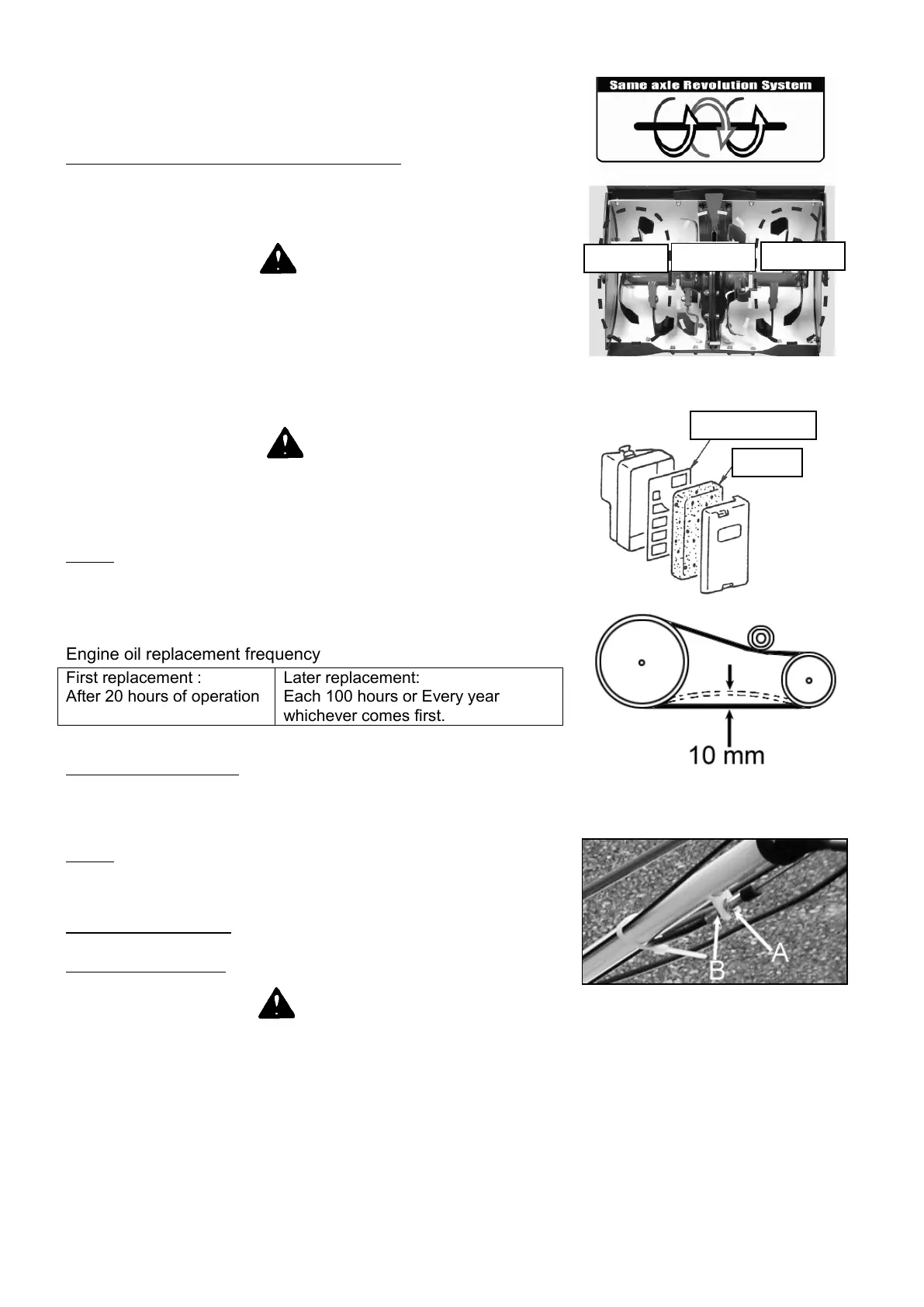

Transmission belt tension

WARNING

A loosen belt may slips and worn quicly, a too tighten belt may worn bearings.

Check for belt condition, cracks and wear. Replace if necesary.

Stop engine, with the engine switch on "stop" position, disconnect the spark plug. Pull out the belt case by unscrewing the

knob.

When the travel lever is pushed down, the lower side of the belt may be pushed from 10 mm (Figure 16).

If this value is not right, adjust it by the tension bolt on the wire (Figure 17).

To increase tension, unscrew the nut A to the top of the machine and screw the nut B to the top. When the adjustment has

been performed, screw again the nut A (Figure 17).

To decrease tension, unscrew the nut B to the low of the machine and screw the nut A to the low. When the adjustment has

been performed, screw again the nut B (Figure 17).

When the adjustment has been performed, replace the belt case and screw the knob again..

Figure 15-2

After 20 hours of operation

Each 100 hours or Every year

Figure 17

Loading...

Loading...