3

English

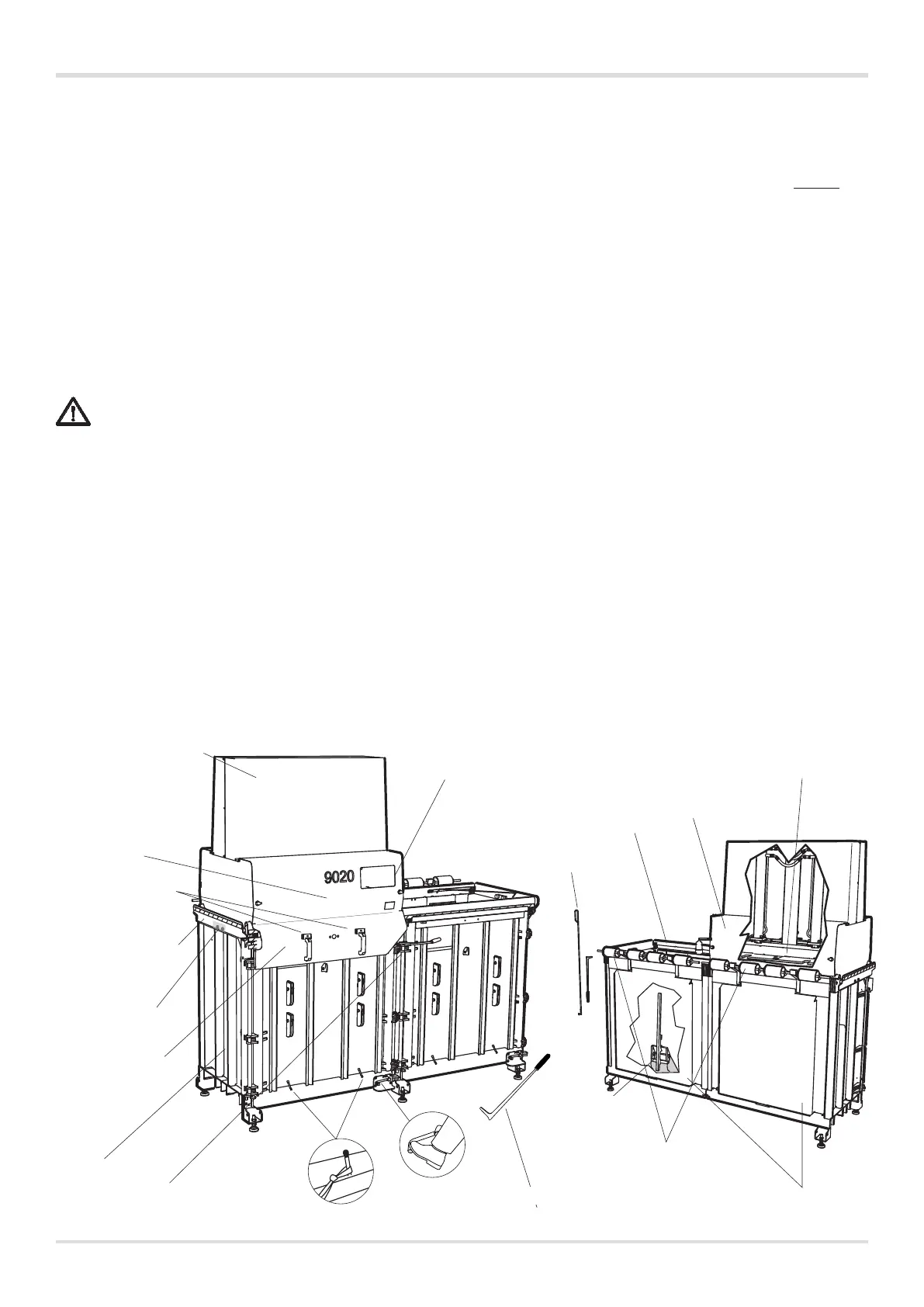

An end guard that prevents crushing.

A stop that prevents the press unit from coming o the rail.

The door pressure is relieved when the door is opened.

Covers for the gas springs.

A brake for the press unit to ensure the operator always uses two hands to move the press unit. Note! If

the power is not switched on when both of the buttons above the handles are kept pressed in, it should be

very dicult to move the press unit.

End guard

Press unit

Stop

Hood

Apron with

handle

Control panel

(please see next page for

more information)

Pedal

Location for strap rolls

Covers for the gas springs

Strap hook

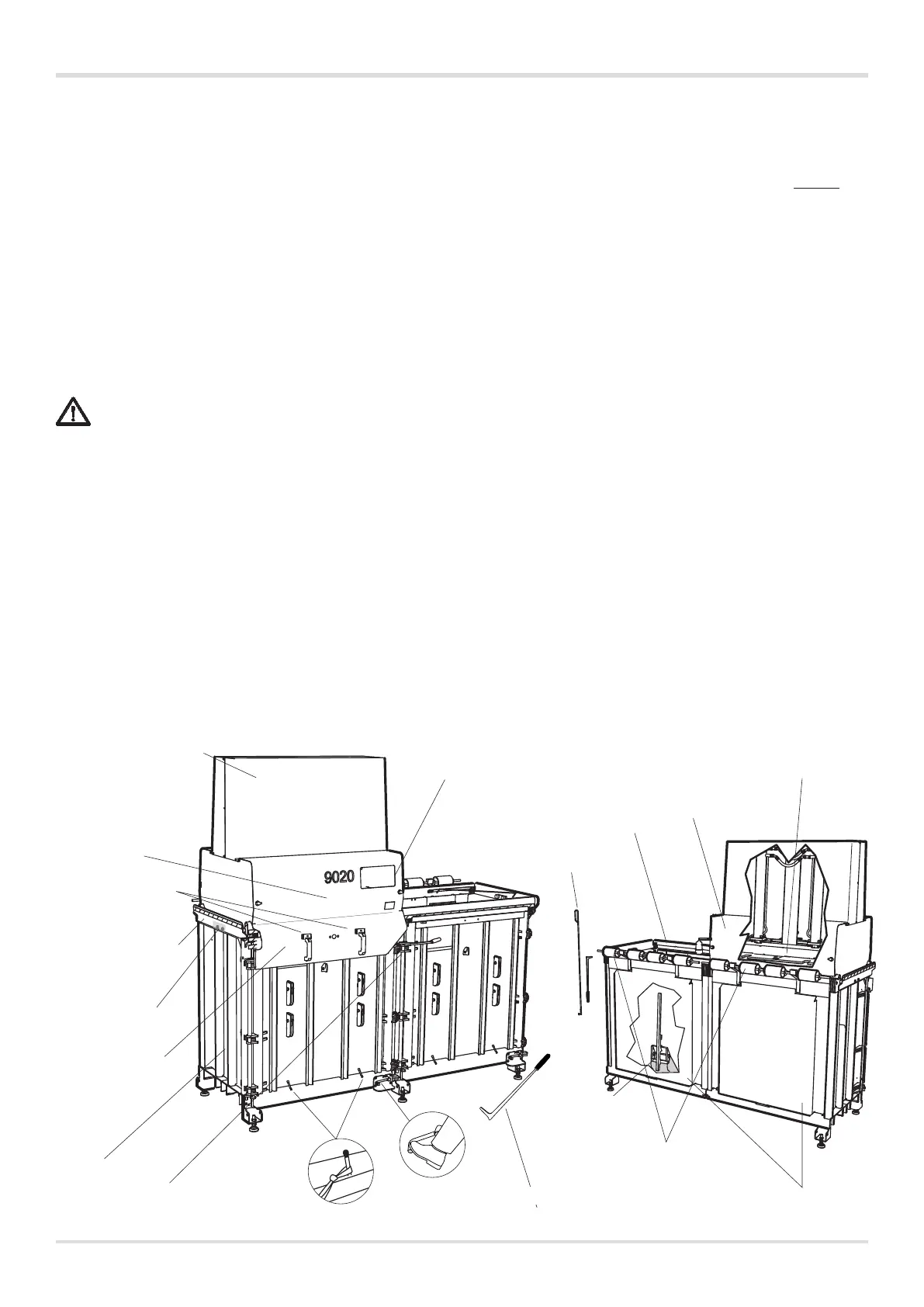

Front cover

Rear cover

Press plate

Bale ejection

mechanism

Pin for straps

FRONT OF THE MACHINE REAR OF THE MACHINE

Chamber

Buttons for

brake

Door and door

handle

Rail

RANGE OF APPLICATION

The machine is a hydraulically operated baler intended for compacting bulky materials such as cardboard, paper and

plastic. The machine can be set to two dierent pressure settings, with the lower pressure setting (12 tons) to be used

for the compaction of plastic. Both pressure settings (12 or 20 tons) can be used for the compaction of cardboard and

paper. The material being compacted should be evenly distributed in the chamber. The machine must only be used

in areas that are provided with a roof, normal lighting and protection against wind. The machine is intended for use in

the temperature range from -10°C to +40°C. A low-temperature oil and/or heater should be used at temperatures lower

than +5°C.

Materials that are ammable or of an explosive nature, such as pressurised containers, etc., which, when exposed

to pressure or sparks, could cause damage, re or an explosion, must not be compacted in the machine.

ENVIRONMENT AND FIRE

In the event of a re, put out burning oil with a carbon dioxide or powder extinguisher. Any re in the electrical system

should be put out with a carbon dioxide extinguisher. If possible, a binding agent for oil should be stored in the immediate

vicinity of the machine, and the system should not be installed directly over or close to drains.

RECYCLING AND DISPOSAL

In the event of the machine being scrapped, the applicable environmental legislation relating to disposal and recycling

should be complied with.

The machine is mainly constructed of sheet steel. It also contains electrical and hydraulic components, as well as

hydraulic oil (the volume of hydraulic oil, in litres, is indicated in the section Technical specications). Furthermore, the

machine is equipped with a gas spring for bale ejection per chamber. These gas springs are located inside each rear

cover and may only be handled and disassembled by authorised personnel.

Clearing tool

Loading...

Loading...