4

PAPER

MAN

AUTO

PLASTIC

+/-

English

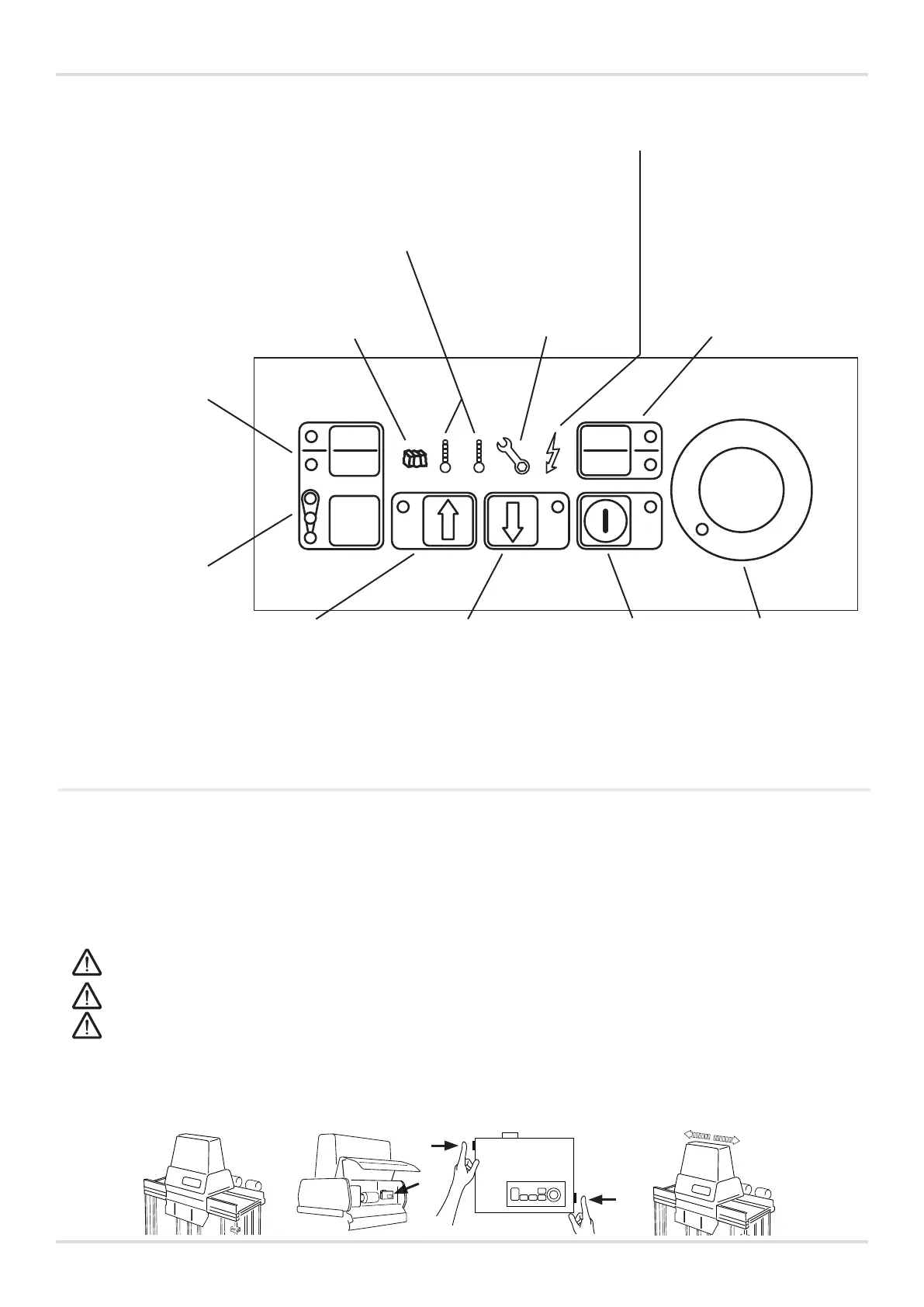

CONTROL PANEL

Paper – indicates that

the machine is set to

compact paper and

cardboard.

The machine operates

using high pressure.

Plastic – indicates that

the machine is set to

compact plastic.

The machine operates

using low pressure. See

Technical specications

for more details.

Do not use the “Paper"

setting when

compacting plastic,

as this may damage

the machine.

Bale size – indicates

the selected bale size

(small - medium -

large).

The bale size can be

locked.

Contact your local

distributor for more

information.

Flammable and explosive materials, such as pressurised containers or the like, which may cause damage, re

or an explosion when exposed to pressure or sparks, must not be compacted in the machine.

Only use straps recommended by the machine manufacturer.

Heavily expanding materials, e.g. bubble wrap, must not be compacted in the machine.

Temperature warning lights

Blue light – indicates that the machine is

cold. The machine may still be operated.

Red light – indicates that the machine has

overheated and may NOT be operated

until it has returned to normal temperature

and the light has gone out.

Bale light – this light

illuminates when it is

time to remove the bale

from the machine.

Service light – see

under TROUBLE-

SHOOTING below for

more information.

Power light – this light indi-

cates that there is power to

the machine.

MAN – indicates that the

machine is set to start

manually. The start button

must be pressed to start

a press cycle.

Up arrow – used

to raise the press

plate to its normal

position.

Down arrow – used

to lower the press

plate. The press plate

will come to a stop

WITH PRESSURE

against the bale in the

lower position (e.g.

for manual baling).

Start – starts a press

cycle (when using

manual start).

Steady LED: the

machine is ready for use.

Flashing LED: the upper

door must be opened

and closed for the press

cycle to be able to start.

Emergency

stop – used if a

press cycle has

to be stopped

immediately.

TROUBLESHOOTING

Flashing service light = fault. First, try removing the plug from the mains and then plugging it back in.

If the fault persists: do not use the machine until an authorised service engineer has rectied the fault. Fault

messages can be interpreted via the service light.

Press the emergency stop button and count the number of ashes, e.g. LED o for 10 seconds followed by 2 ashes.

For optimal service assistance – specify the ashing message when reporting the fault.

Service light, steady light = time for servicing. Contact your authorised service engineer.

The machine can continue to be operated.

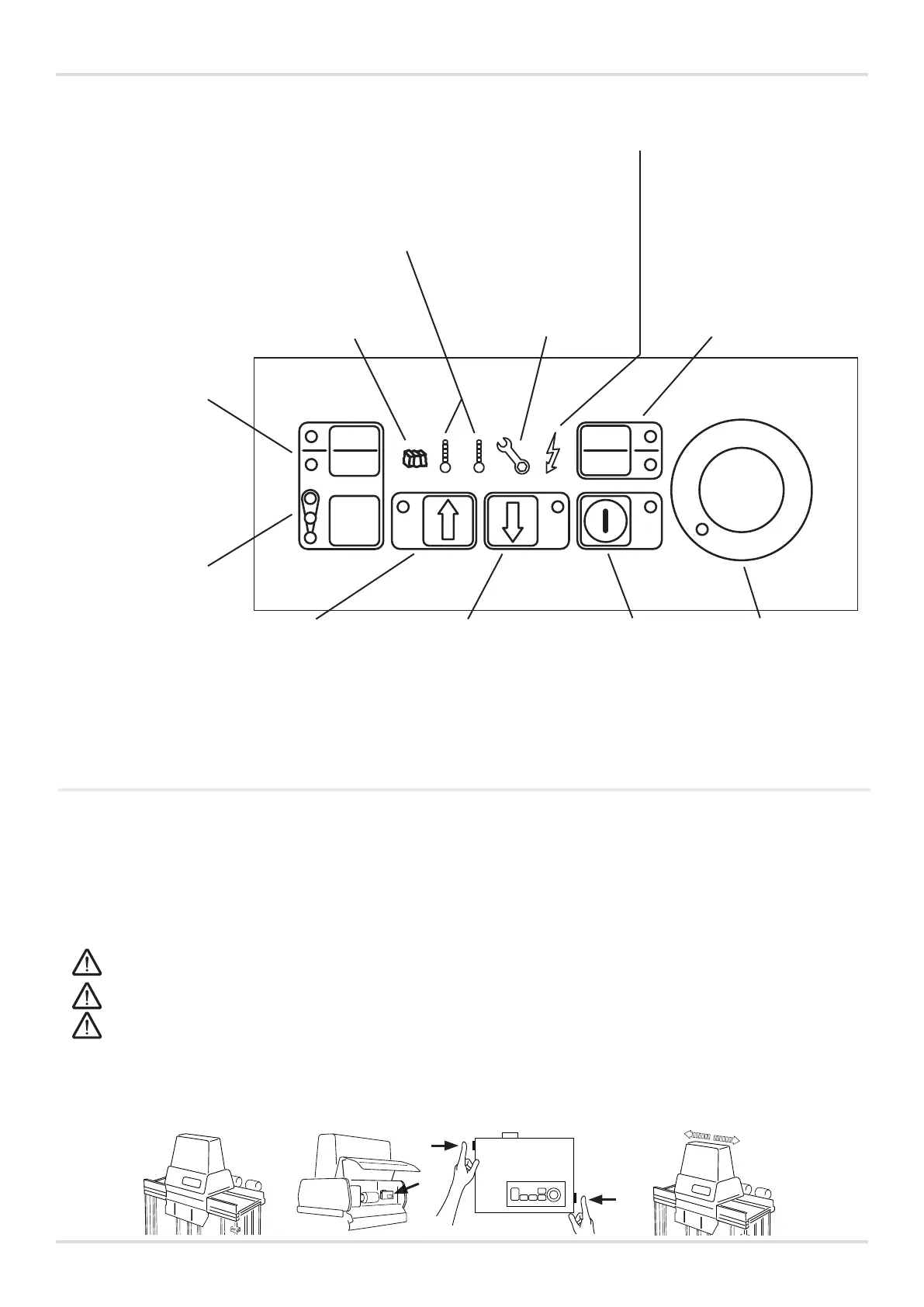

IF THE PRESS UNIT IS POSITIONED BETWEEN THE CHAMBERS AND HAS BECOME STUCK

Open the front cover and press the buttons located on the sides of the electrical controls. Press both buttons

simultaneously until the press plate is in the correct position and the machine has come to a stop. Then move the

press unit so that it is over the desired chamber.

Loading...

Loading...