7

A

A

STOP

100 mm

OFF

ON

OFF

PAPER

MAN

AUTO

PLASTIC

+/-

PAPER

MAN

AUTO

PLASTIC

+/-

PAPER

MAN

AUTO

PLASTIC

+/-

B

B

1

32

4

6

7

5

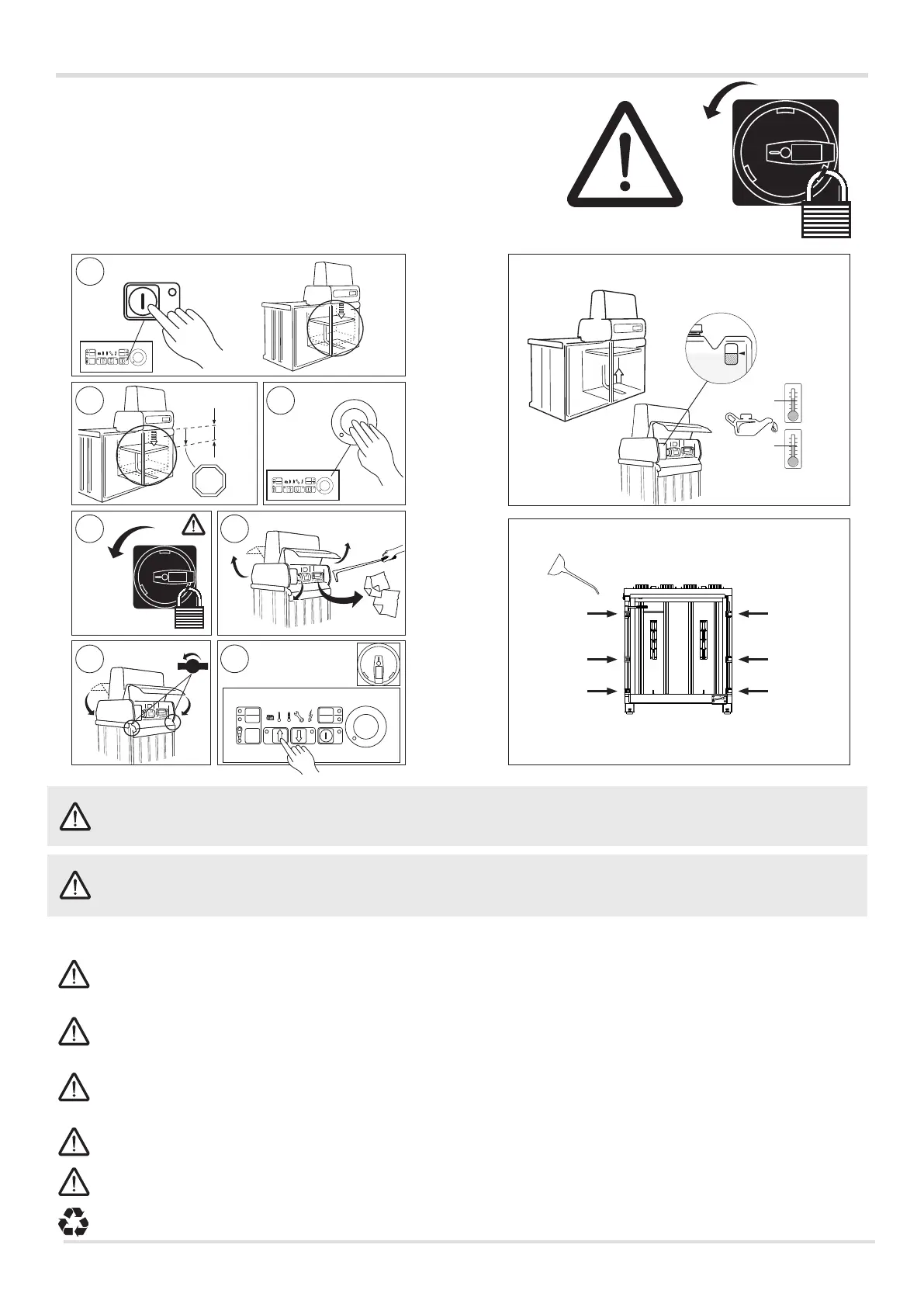

max

min

Hydraulik oil

VG 32-68

Mineral oil

Special oil

>+5°C

<+4°C

0

OFF

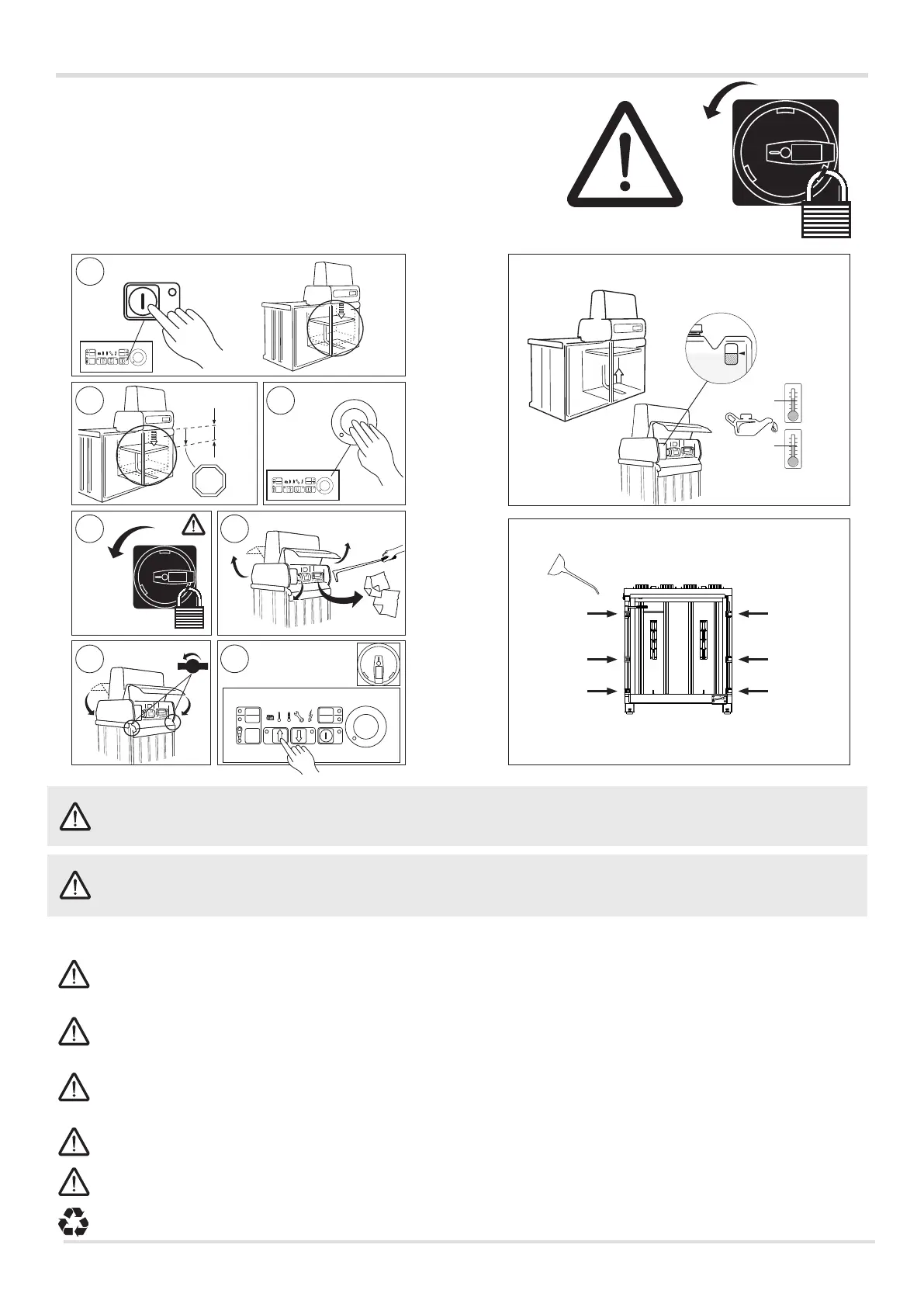

NOTE! During inspection and maintenance, servicing and the

removal of trapped waste, etc:

1. Always turn the main power switch to “0” and secure it

with a padlock.

2. Do not work inside the machine.

WEEKLY INSPECTION AND MAINTENANCE

CLEAN THE PRESS PLATE

(removal of material)

CHECK THE OIL LEVEL

LUBRICATE THE CHAMBER

SAFETY CHECKS

- Check that the emergency stop is working.

- Check the hatch switch: the machine should not be able to start if the front or rear hatches are open or opened.

- Check the end guards (there are 2) and the stops (there are 2). Make sure that they are in place and

rmly attached.

- Check that the power cable is intact and well protected from impact, and that it is well away from the rail.

- Check that there are no oil leaks on the machine.

- Check that no parts are loose or damaged. NOTE! The apron is essential for safety reasons!

- Check the function of the brake. NOTE! If the power is not switched on when both of the buttons above

the handles are kept pressed in, it should be very dicult to move the press unit.

- Check that the machine is level, i.e. that it is easy to move the press unit between the chambers.

If any fault is found in the functions above, the machine must not be used until it has been repaired by

authorised service personnel.

Servicing and repairs must only be carried out by qualied personnel, and in accordance with the

machine manufacturer’s instructions.

When changing the oil: contact the local authorities for guidance regarding the environmentally correct

disposal of waste oil.

WARNING!

If any of the machine’s covers are removed during maintenance/repair, these must be retted before the

machine can be operated.

WARNING!

Adjustments and repairs to the gas spring at the rear of the chamber may only be carried out by

authorised personnel.

English

Loading...

Loading...