GENERAL FAN FACTS

31

Sound data explanation

SOUND DATA IN THIS

BROCHURE IS BASED ON FOL-

LOWING DEFINITIONS:

The points for which the sound data is present-

ed are along the system line defined by the

pressure and flow stated in the sound data table

for each fan. There are three types of sound in

these tables; inlet- and outlet sound are mea-

sured in duct, while the surrounding sound is

measured outside the fan and duct system. For

all these types of sound, the sound power levels

are presented in octave bands. For the sur-

rounding sound, also the sound pressure level

has been calculated.

THE SOUND POWER LEVEL

The sound power level, Lw(A) is used to calcu-

late the sound from the whole ventilation sys-

tem. This system can be a composition of gril-

les, dampers and diffusers for example.

The sound power level is a measured value

according to standards, and it does not tell how

the sound appears as the sound power is inde-

pendent of the characteristics of the placement

of the fan. In order to resemble the human ear,

the A-filter is used indicated with Lw(A) mea-

sured in dB(A).

THE SOUND PRESSURE LEVEL

The sound pressure level, Lp or Lp(A), tells

how the human ear registrates the sound. It is

dependent on the sound power level, distance

from the source, restrictions of the propagation

and the accoustic characteristics of the room.

The sound pressure level is presented for a

room with an equivalent absorption area of

20 m

2

. 7 dB difference correspond to a distance

of ca 3 m, where the sound is emitted in a semi

spherical propagation.

The sound pressure level can be calculated as:

Lp=Lw + 10Log (Q/4πr

2

+ 4/A)

A= is the room’s equivalent absorption area

Q= is the propagation type:

Q=1 is spherical propagation

Q=2 is semi spherical propagation

Q=4 is quarter spherical propagation.

For the free field case, i.e. from a roof fan, the

sound pressure level is calculated as:

Lp=Lw + 10log Q/4πr

2

.

With Lw(A) tot at 63dB(A), a distance of 5

meters, semi spherical propagation and free

field case, the result will be:

Lp(A)= 63 +10log 2/4π5² = 63-22= 41 dB(A)

And at 10 meters:

Lp(A)= 63 +10log 2/4π5² = 63-28= 35 dB(A)

In pressure/flow diagrams or in the table of

technical data there are facts about highest tem-

perature of transported air.

All motors have insulation class F which

means that the thermal contact disconnects the

power when the winding temperature is maxi-

mum 155°C. At this winding temperature the

life time of the ball-bearings is not optimal. This

is why the ambient temperature is shown at a

lower winding temperature so the life time of

ball-bearings becomes optimal.

The winding temperature variates in the

diagrams and depending on differences in

power/current consumption. The temperatures

in our diagrams are given at the highest winding

temperature.

Temperature of transported air

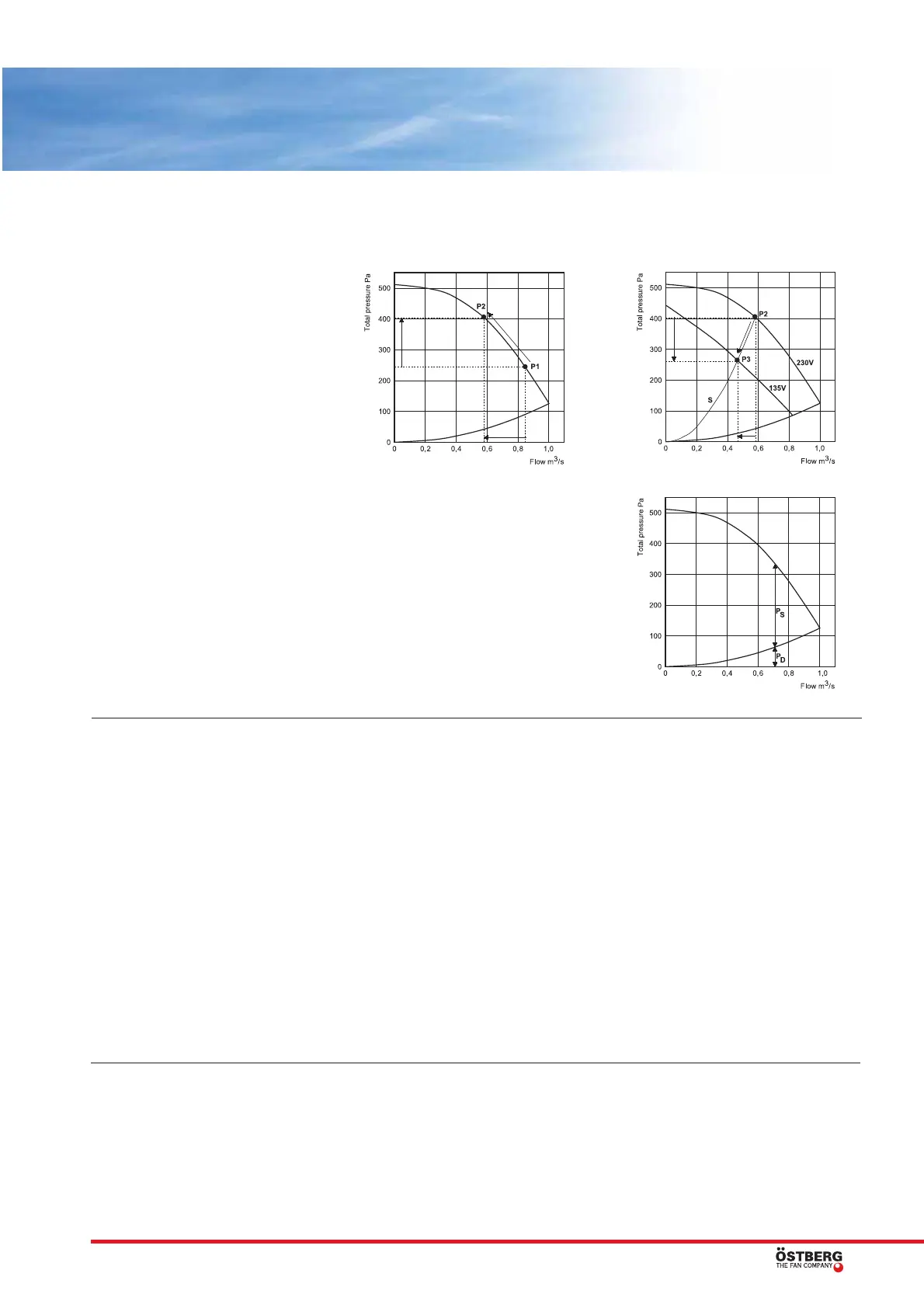

FIG. 1:

The fan curve describes the capacity of the fan,

i.e. the flow of the fan at different pressures at a

certain input voltage.

The fan diagram has the pressure in Pascal,

Pa, on the vertical axis and the flow in cubic

metres per second, m

3

/s, on the horizontal axis.

The point on the fan curve showing the

current pressure and flow is called the fans wor-

king point. In our example it is marked with P.

If the pressure increases in the ducts, the

working point moves along the fan curve and

hence a lower flow is obtained. In the example

the working point would move from P1 to P2.

FIG. 2:

The system line describes the total behaviour of

a ventilation system (ducts, silencers and valves

etc.).

Along this system line, S, the working point

is moved from P2 to P3 as the rotational speed

is changed.

Distinct voltage steps with eg. a transfor-

mer produces different fan curves, 135 V and

230 V, indicated in the example.

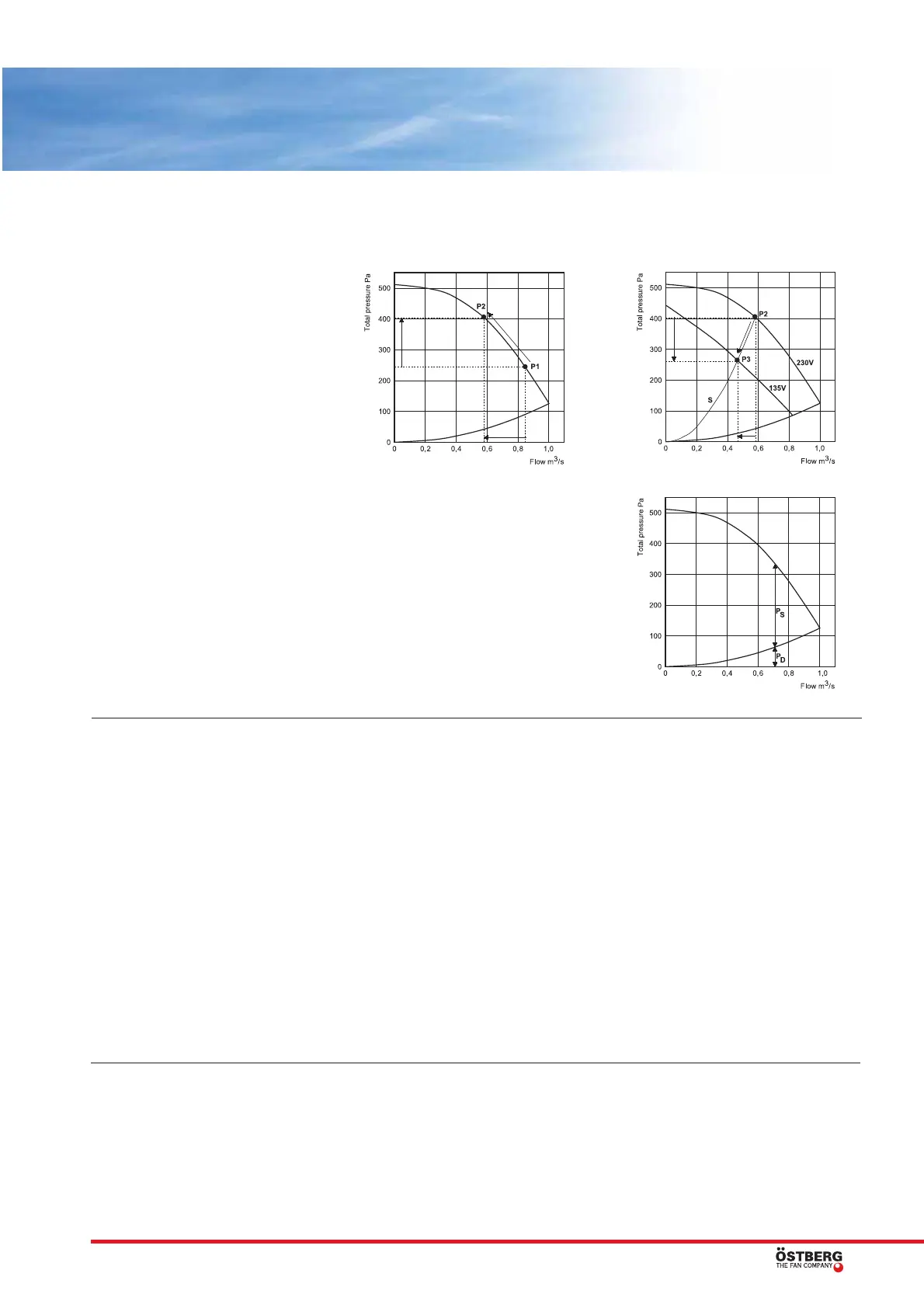

FIG. 3:

Our fan curves present the total pressure in

Pascal. Total pressure = Static + Dynamic pres-

sure.

The static pressure is the pressure of the

fan compared to the atmospheric pressure. It is

this pressure that shall overcome the pressure

losses of the ventilation system.

The dynamic pressure is a calculated pres-

sure that arises at the outlet of the fan, and is

mostly due to air velocity. The dynamic pressu-

re thus describes how the fan is working. The

dynamic pressure is presented with a curve,

starting at origo, that increases with increased

flow. A high dynamic pressure can with wrong

duct connection produce a high pressure loss. If

the pressure loss in the system is known, a fan

whose difference between the total and the

dynamic pressure corresponds to the pressure

loss in the system must be found.

Pressure/flow-curves explanation

FIG. 1:

FIG. 2:

FIG. 3:

Loading...

Loading...