Do you have a question about the Overhead door Signature Screw Drive and is the answer not in the manual?

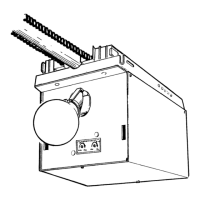

| Drive System | Screw Drive |

|---|---|

| Horsepower | 1/2 HP |

| Remote Control | Yes |

| Maximum Door Weight | 500 lbs |

| Security | Rolling code technology |

| Battery Backup | No |

| Voltage | 120V |

| Safety Sensors | Yes |

| Speed | 7 inches per second |

| Warranty | Lifetime Motor Warranty |

Disable door locks, clear obstructions, and follow general warnings.

Non-contact beam that reverses door during down travel if beam is broken.

Contact system that stops and reverses door within 2 seconds of contact.

Timed system that automatically opens door if not closed within 30 seconds.

Adjustable control to set minimum force required for door operation.

Security system that changes access code with each remote use for enhanced security.

Identifies potential hazards like moving doors, electrical shock, and spring tension with safety term definitions.

Critical instructions for safe and proper installation of the opener to prevent injury.

Key warnings and checks to perform before beginning opener installation.

Drilling pilot holes and fastening the header bracket securely using lag screws.

Mounting the power head using straps or angle iron, anchored to garage framework, not drywall.

Splitting, stripping, and connecting wire ends to STB terminals securely.

Connecting STB wires to terminals #3 and #4 on the power head unit.

Ensuring no obstructions in beam path and lenses are 5-6 inches above floor.

Plugging the operator into a grounded outlet and performing STB alignment check.

Setting the force required for the door to open smoothly and reliably.

Setting the force required for the door to close safely and reliably.

Performing a test to ensure the door reverses upon contact with an object.

Adjusting closing force or limit switch if door does not reverse properly.

Step-by-step instructions to program a single-button remote control to the opener.

Instructions to program each button on a multi-button remote for different operators.

Procedure to erase all programmed remote control memory from the receiver unit.

Instructions on safe operation, keeping clear of moving doors, and child safety with remotes.

Procedure for monthly testing of the door opener's safety reversal function.

Importance of keeping doors properly balanced and serviced by qualified personnel.

Procedure to check if the door is properly balanced by releasing the carriage.

Performing the contact reverse test using a 2x4 board on the floor.

Understanding LED status codes for troubleshooting Safe-T-Beam system issues.

Steps to take for various Safe-T-Beam system malfunctions, including contacting service.

Diagnosing issues when the wall control fails to operate the opener.

Troubleshooting unexpected door movements, possibly due to lost remotes or stuck buttons.

Resolving issues where the door stops prematurely during closing or opening.

Diagnosing problems when the operator runs but the door remains stationary.

Loading...

Loading...