TECHNICAL MANUAL "SE" (PBM753) Revision no. 1 dd. 01/02/2017

P.B.M. S.r.l. via Barella, Z.I. - VIGNOLA ( MO ) ITALIA Tel. + 39 (059) 7705311 Fax + 39 (059) 7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: Manuale SE PBM753 GB rev.1.doc

page 16

• If strong vibrations are heard during the charging process and the charging process is not performed

regularly because the cut-out-switch or the fuses operate, it means that the bridge is in short-circuit and

it needs replacing.

• On the other hand it is easy to diagnose the open bridge failure on a three-phase charger by operating

the charger without connecting the battery and forcing the power supply of the transformer. If an

anomalous transformer voltage, instead of a no-load voltage, is detected under these conditions, it means

that the rectifier bridge is at least partially open and needs replacing.

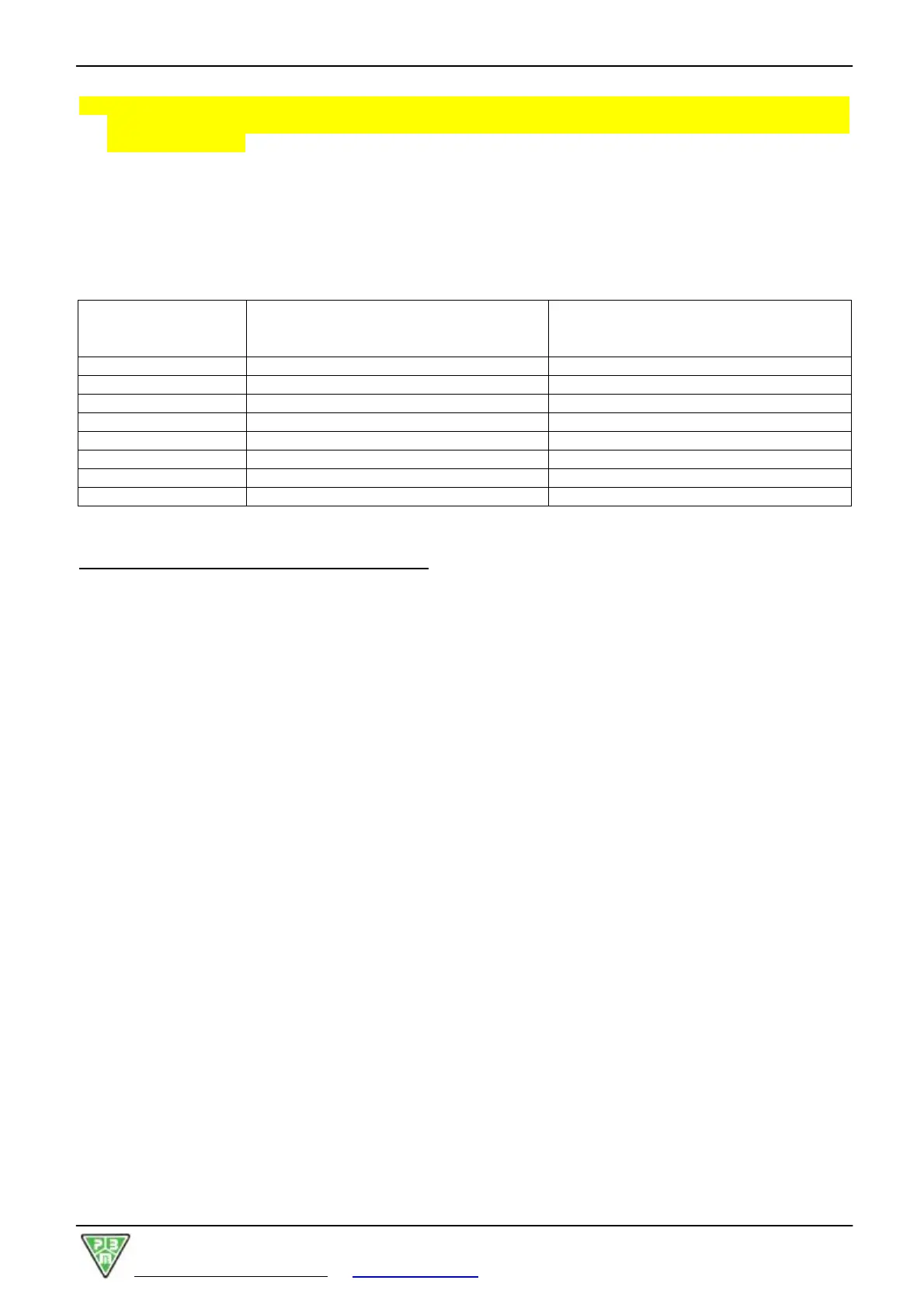

• As for single-phase and three-phase battery chargers, the no-load output voltage corresponds to the

values contained in the following table (provided that transformer is correctly powered).

RATED BATTERY

VOLTAGE

NO-LOAD OUTPUT VOLTAGE (DC)

FOR A SINGLE-PHASE BATTERY

CHARGER

NO-LOAD OUTPUT VOLTAGE (DC)

FOR A THREE-PHASE BATTERY

CHARGER

12V 14 ÷ 15V 18 ÷ 24V

24V 28 ÷ 30V 33 ÷ 38V

36V 42 ÷ 44V 50 ÷ 58V

40V 46 ÷ 48V 60 ÷ 70V

48V 56 ÷ 58V 72 ÷ 80V

72V 85 ÷ 87V 100 ÷ 108V

80V 95 ÷ 98V 110 ÷ 120V

96V 112 ÷ 115V 130 ÷ 150V

CHAPTER 11 : MAINTENANCE AND CLEANING

All maintenance and cleaning processes have to be performed by qualified, skilled, and authorised

personnel.

• Since the battery charger is an electrical equipment without any moving mechanical part, it does not need

any special maintenance.

• It is however suggested to check, inspect, and clean the charger at least once a year if it operates in a

fairly “clean” environment.

• In “hard” conditions, that is in dusty and wet environments, checks have to be performed more frequently.

The main checks to be performed are the following:

− Place the charger/s outdoor and remove the closing panel.

− Wear a faceplate and protection devices. Using compressed air, remove dust accumulated inside the

charger.

− Use non-corrosive detergents to remove sludge deposits or other dirt.

Once the charger has been cleaned, perform the following actions:

− Check the general condition of components and their integrity.

− Replace oxidized cables and/or terminals, if any.

− Use proper sprays to clean electrical contacts on contactors, switches, and commutators.

− Check the tightening of screws and bolts, replace the rusted items, if any.

− Perform a “dry cleaning” or use proper sprays to clean electronic cards.

− Check the status of both control and power connectors. Check the “wear” of power connectors and

replace them, if necessary.

− Check the condition of electrical plugs.

− Once all the above-mentioned operations have been performed, close panels, doors and covers again,

and place the charger/s in its/their position/s again.

Loading...

Loading...