76

2.4.

Pumps resorting under the 2014/34/EC directive (ATEX)

PACKO pumps according to 2014/34/

EC are designed and manufactured

to reduce as much as possible the

risk of explosion. Nevertheless, the degree of

explosion safety of the pump in the installation

can only be assured by the joint precautionary

measures of the pump constructor PACKO and

the user.

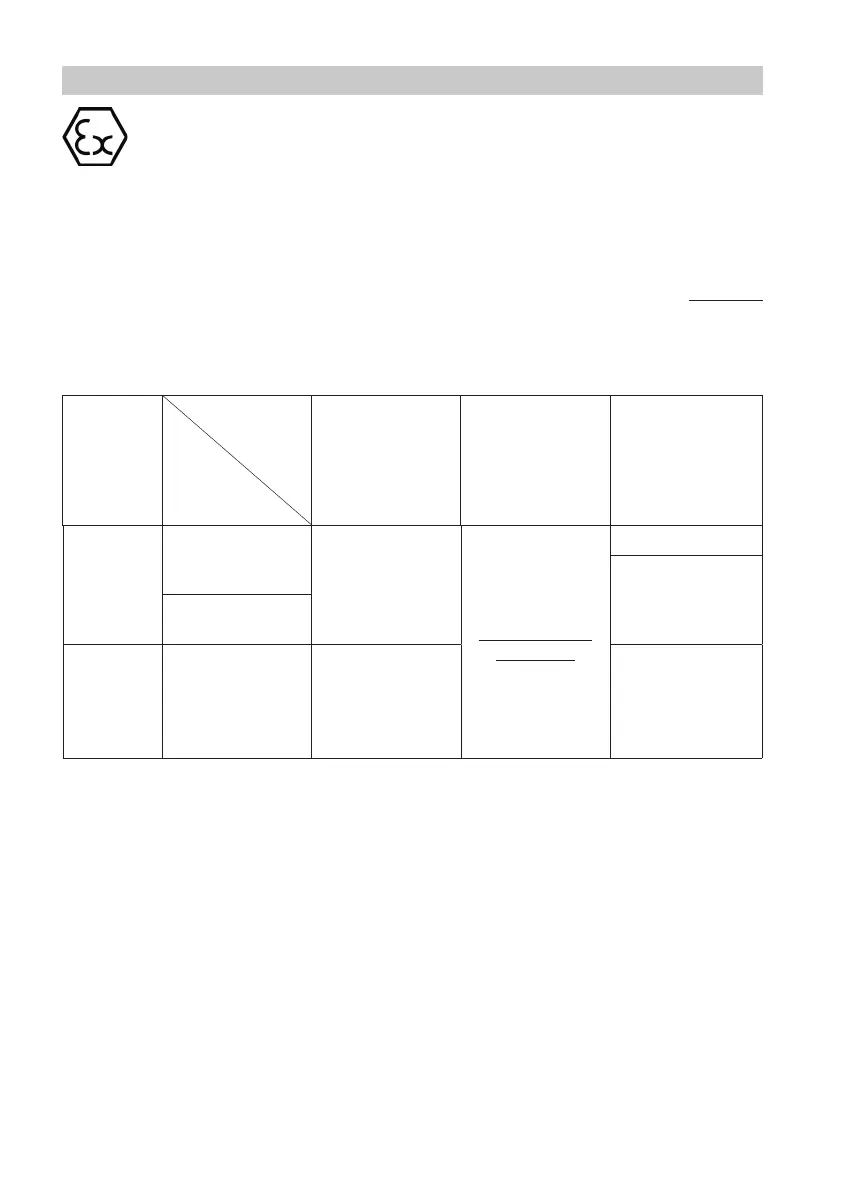

The table below shows an overview of the risks

by pump type and whether the pumped liquid is

inammable, as well as the preventive measures

available.

The cells in the table where the text is italicized

indicate the absence of the risk.

The cells in the table where the text is in bold

indicate risks prevented by modications to the

pump by the constructor PACKO. The modica-

tions can only prevent the risk through proper

use by the end-user.

The cells in the table where the text is underlined

indicate risks that the user must avoid.

Pump

Risk

Liquid

Dry-running

mechanical seal

(Friction faces

overheated are

source of ignition)

Operating with

closed valve

(The outside wall

temperature can

be above the

temperature class)

Leak

(igniting liquid can

be release into

atmosphere)

Flooded

suction

Non-ignitable

liquid

Flushed seal

or temperature

control of seal or

ow monitor by

user

Flow monitoring

by the user

No danger

Flushed seal

or preventive

maintenance by

the user

Ignitable liquid

Air handling

or self-

priming

Non-combustible

liquid

Flushed seal No danger

Normal-priming pumps are pumps from the

series FP, NP, ICP, PHP, MCP, MFP, MWP, FPP,

IPP, SFP, FMS and NMS.

Air-handling pumps are pumps from the series

CRP, IRP, and PRP.

Self-priming pumps are pumps from the series

MS P.

The ashpoint of a liquid is the lowest tempera-

ture at which sufcient vapour is created above

a liquid so that it can ignite when mixed with air.

A combustible liquid is not ignitable as long

as the temperature is lower than the liquid’s

ashpoint. It is important to note that specic

components (primarily the mechanical seal and

the motor) of the pump can be warmer than the

temperature of the liquid being pumped. When

a mechanical seal runs dry, it becomes very hot

(up to 400°C +). As a result, a liquid with a ash-

point that is much higher than the temperature

at which it is being pumped must nevertheless

be considered as potentially inammable when

assessing the risk of dry running of the mechan-

ical seal and the risk of leaks.

Loading...

Loading...