91

ENG

•

After rinse - The reason for the after rinse

is to remove all loosened dirt and detergent.

•

Disinfection - The disinfection reduces the

number of toxic micro-organisms to an accept-

able level. However, the disinfection does not

guarantee full sterility and is only sensible

after a good cleaning.

• Final rinse - The nal rinse has to be done

with germ-free water with a total hardness

below 5 °D (90 mg/l CaCO3). The nal rinse

water is often used for pre rinse.

7.

Problem solving

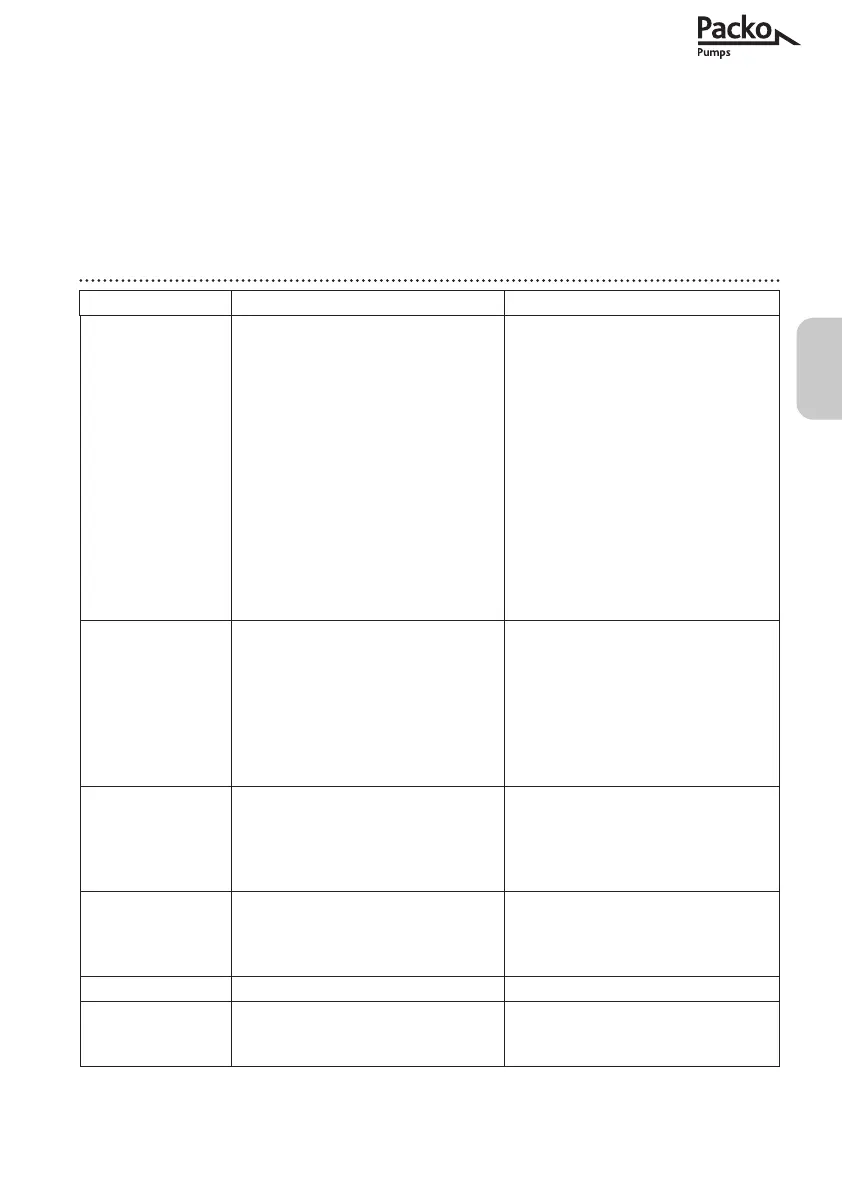

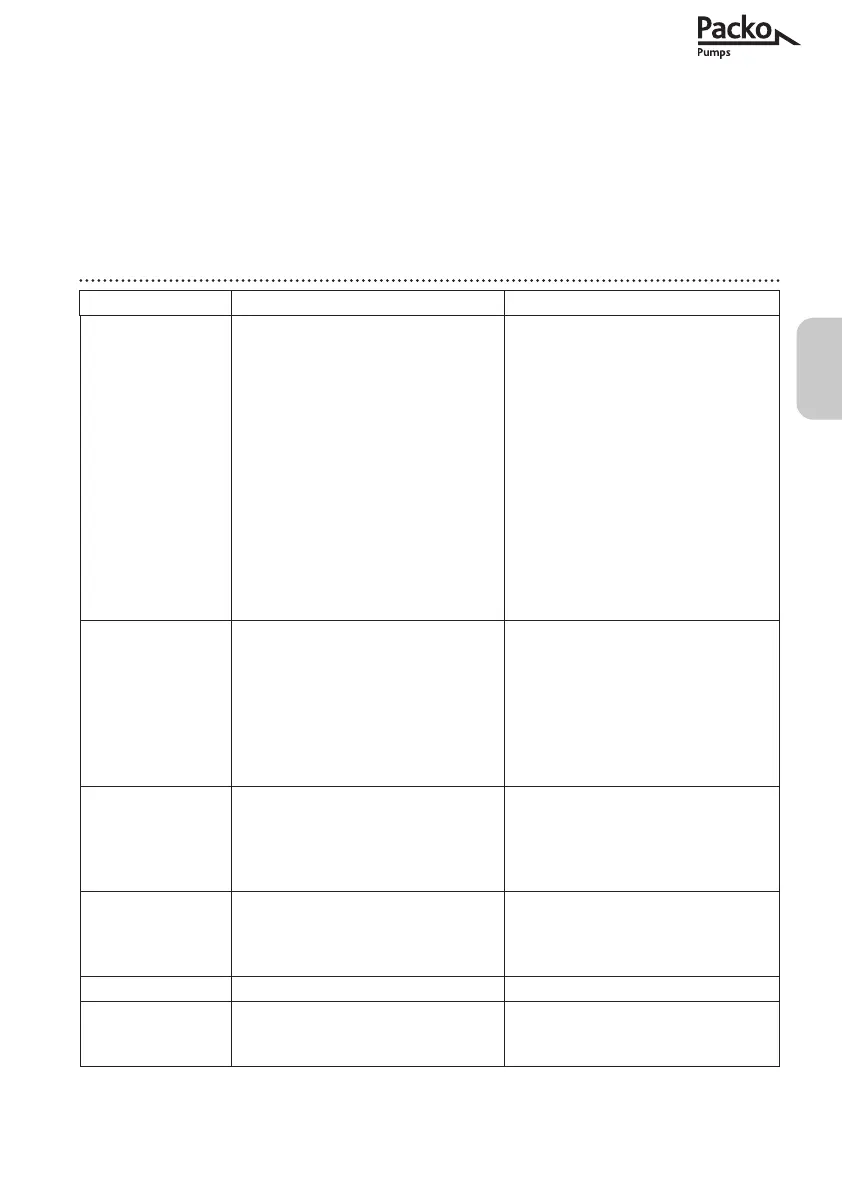

Failure Possible cause Solution

There is no suction • Wrong direction of rotation

• Valve in suction line or pressure

line closed

• Synthetic plugs are still in inlet or

outlet

• Insufcient de-aeration

• For self-priming pumps: pressure

on outlet of pump too high

• Change two terminals

• Open valves

• Remove plugs

• De-aerate better

• Open all valves completely,

decrease pressure in discharge

vessel, make provisions so that

no liquid column can be built up

on the outlet of the pump, remove

any non-return valve from the

discharge pipe and, if necessary,

install it directly on the suction of

the pump.

Pump ow is too

low

• There is no suction

• Wrong direction of rotation

• Valves are not opened enough

• Impurities in the pipe work

• Pump draws air

• Air pockets in the suction line

• Wrong motor connection

• See above

• Change two terminals

• Open valves

• Clean pipes

• Stop leakages in suction line, raise

level in suction tank

• De-aerate

• Reconnect in the right way

Pump produces

low pressure

• Wrong direction of rotation

• Cavitation

• Motor is running too slow (fre-

quency converter)

• Wrong motor connection

• Change two terminals

• See below

• Raise frequency

• Reconnect in the right way

Cavitation (pump

makes a cracking

noise, pump hunts

on/off line)

• Friction losses in suction line too

high

• Liquid temperature too high

• Liquid level in suction tank too low

• All valves in suction line must be

completely open, enlarge diameters

• Cool down liquid

• Fill up tank or lower pump

Pump ow too high • Friction losses too low • Close valve in discharge pipe

Pump blocks • Pump wrongly assembled

• Foreign body in the pump

• Disassemble and assemble in the

correct way

• Clean

Loading...

Loading...