73

ENG

2.3.

Warnings and safety notes

The pump may never be used inde-

pendently. It is intended to be

incorporated into machinery.

There must always be piping connected to

the inlet and the outlet.

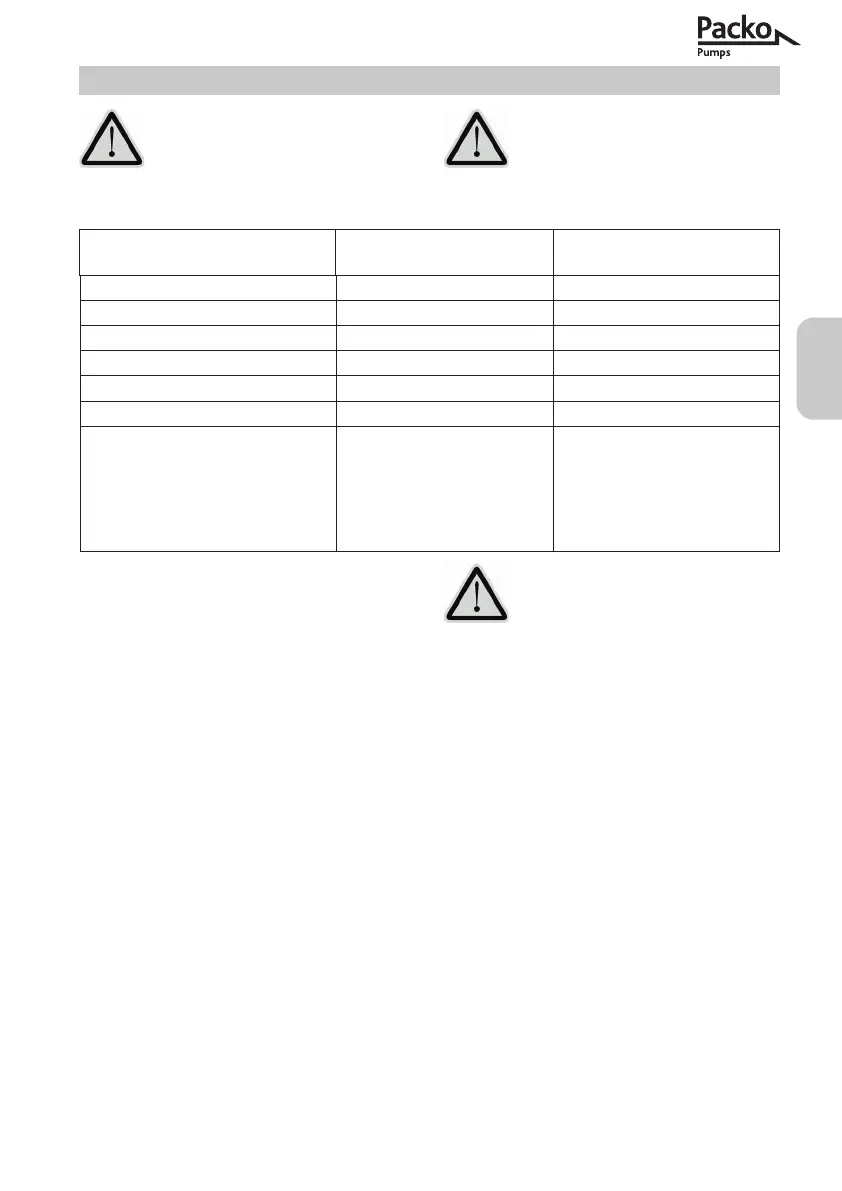

The pressure in the pipe work

should not exceed the following

values:

Pump type Maximum pressure of

pumps with open impeller

Maximum pressure of

pumps with closed impeller

FP4100 – FP4600 Max 0.7 bar on the inlet

FP, NP and IFF 63, 66 and 68 Max 5 bar on the inlet

VPC, VDK and AX series Max 2 bar on the inlet Max 4 bar on the outlet

MSP series Max 2 bar on the inlet

FMS, NMS, FP1 and ICP1 series Max 6 bar on the inlet

FPP, IPP Max 40 bar on the inlet

All other pump series

Types 125

Types 160 and 185

Types 200

Types 250

Types 315

Max 13 bar on the inlet

Max 10 bar on the inlet

Max 4 bar on the inlet

Max 3 bar on the inlet

Max 10 bar on the outlet

Max 12 bar on the outlet

Max 15 bar on the outlet

Max 8 bar on the outlet

The values mentioned above are the maxi

mum

allowed pressures for pump casing and

backplate.

The maximum allowed pressure for the complete

pump depends on the type

of the mec hanical seal. The

values mentioned

above are only valid with a sterile

balanced

mechanical seal. (seal con gurations A, B,

C

or H). It is advisable to make arrangements that

restrict the pressure on the outlet of the

pump.

The maximum allowed speed of the pump is

limited through:

• The maximum pressure in the pipe work (see

above)

• The motor power. When the pump is turning

faster, it needs more power.

•

The maximum speed can never be higher than

3600 revolutions per minute

When the motor turns very slowly, its own cool-

ing can be affected. The minimum speed for

pumps with a two-, four- or six-pole motor is

15 Hz and 25 Hz for pumps with a 8-pole motor.

The maximum allowed temperature

of the pumped liquid depends on the

seals in the pump and the vapor pres-

sure of the pumped liquid. For more speci c

details, we advise you to contact PACKO. In

general you can choose the smallest of the fol-

lowing limitative values:

A. Maximum temperature for the rubber

(depending on the liquid): 90°C for perbu-

nan, 125°C for EPDM, 200°C for Viton, FEP

and Kalrez, 110°C for silicone.

B. Pumps with a simple mechanical seal: 15°C

lower than the boiling point of the pumped

liquid at the pressure on the inlet of the

pump. Pumps with a ushed seal (quench or

double seal) support a higher temperature if

the sliding surfaces of the mechanical seal

are suf ciently cooled down.

C. To guarantee good lubrication of the

motor bearings, special motors have to

be used for the handling of liquids with a

temperature higher than 150°C.

Loading...

Loading...