82

The diameter of the suction pipe should be at

least as great as the inlet diameter of the pump.

In order to prevent cavitation, the suction pipe

should have a hydraulic resistance that is as low

as possible. This means it should be as short

as possible, contain no lters and the minimum

number of bends possible. Bends should have a

large radius. When there is a bend at a distance

less than 0.5 m or 8 times the suction diameter

before the pump, the pump’s efciency can be

inuenced.

All valves in the suction pipe should be full bore.

When there is a possibility the storage tank con-

tains particles, the connection of the suction pipe

on the tank must be at least 1.5 times the diam-

eter of the suction pipe above the bottom of the

tank. It is recommended to also put a screen

in those situations. In no way should the liquid

coming into the pump contain particles of more

than 0.25 mm. (Except for VPC, VDK, MFF, MWP

and IFF pumps, which are suited to circulate food

particles.) When the liquid may contain particles,

this must be mentioned when ordering the pump

in order to select the right mechanical seal.

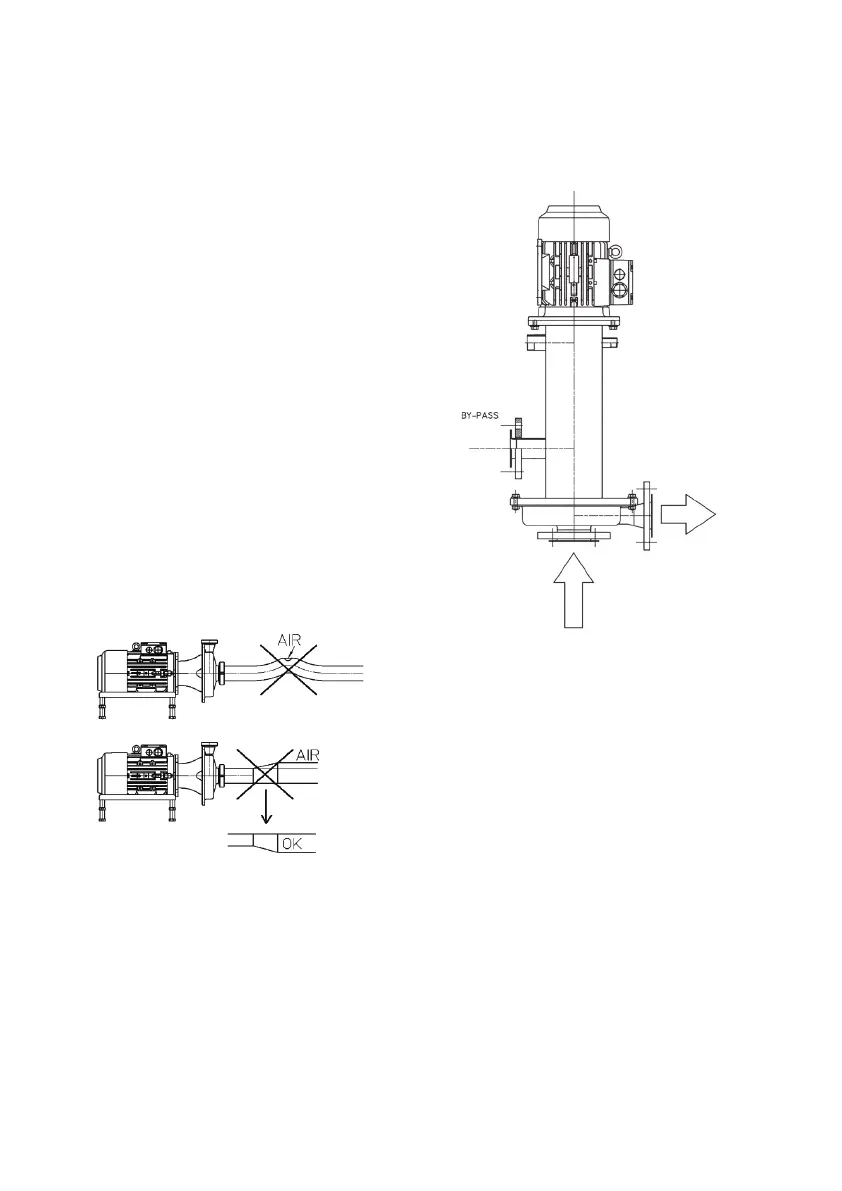

To prevent air traps, the suction pipe must con-

tain no bridges (a part of a pipe that has both

ends lower than the middle) and should have

an ascending gradient of 1 % toward the pump.

Pipe reducers should be of an eccentric type

and installed so that no air can be trapped (not

for MSP, CRP, PRP and IRP). Install the suction

pipe in a way that the liquid ows automatically

into the pump. (Not for self-priming pumps MSP)

If the level of the liquid in the suction vessel is

less than 8 times the diameter of the suction pipe

above the inlet of the pump, an anti-vortex device

has to be installed in the suction pipe to prevent

air from being drawn into the pump.

For pumps with a drain valve on the pump casing,

this drain must be connected to a piping that’s

pressureless in order to guarantee draining of

the pump. If the drain valve is operated electri-

cally or pneumatically, the operation of the drain

valve must be integrated in the control circuit of

the installation or machine in which the pump

is integrated.

The length and diameter of the discharge pipe

will determine the operating point of the pump.

The pump selection is based on the information

given together with the inquiry. It is therefore

important that the discharge pipe work installa-

tion is carried out according to the same plans

as those used for the pump selection. It is rec-

ommended to install a pressure gauge directly

on the outlet of the pump.

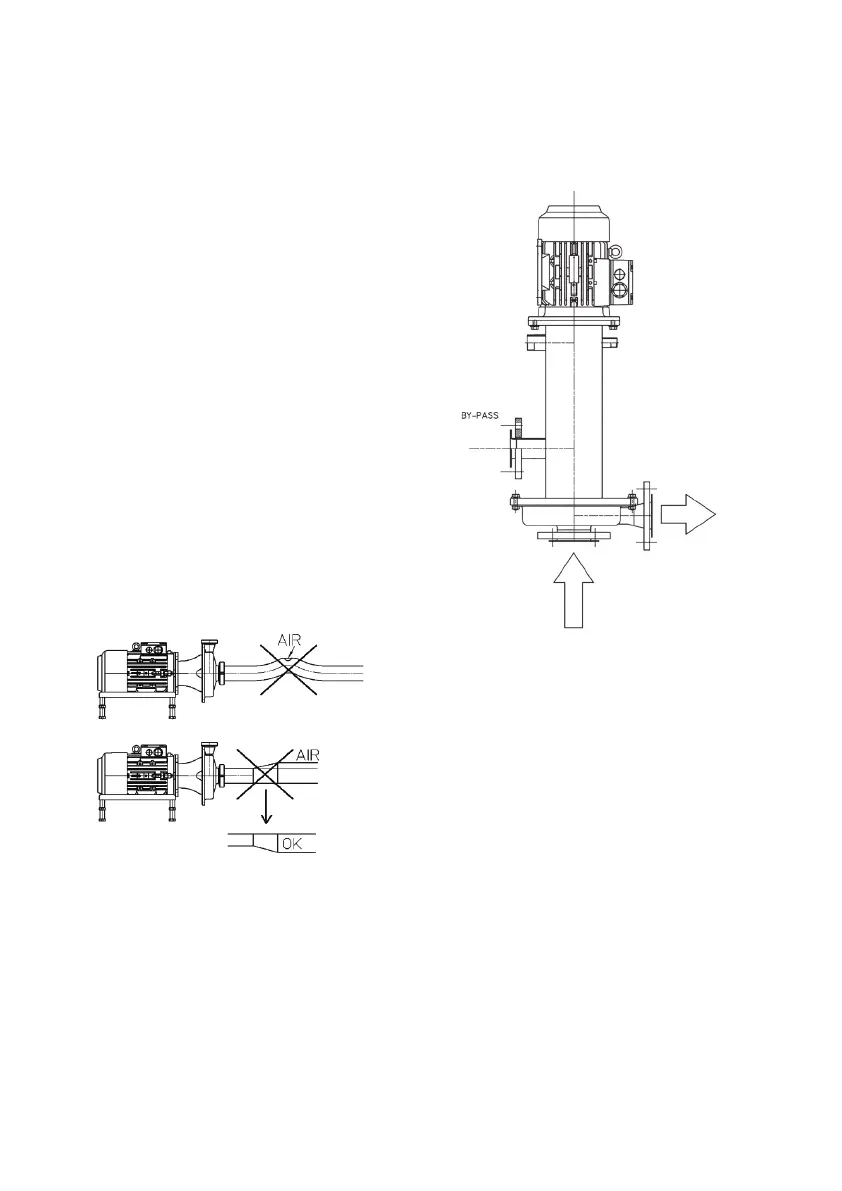

For the externally mounted pumps in the series

NPIMO, ICPIMO and MCPIMO there is a by pass

Loading...

Loading...