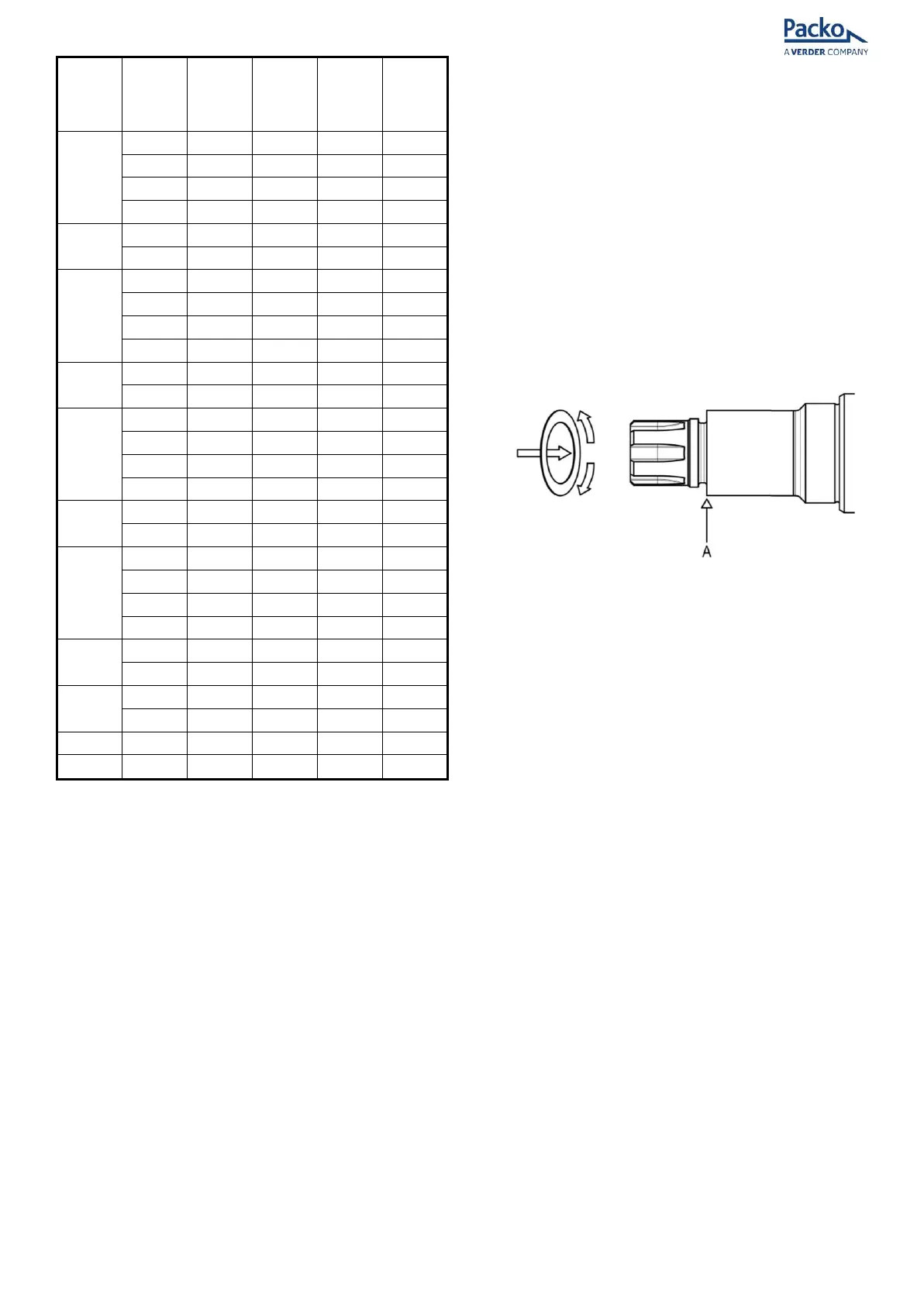

Table 6 - Rotor clearances (all values in mm)

Axial Clearance: Scimitar and Tri Lobe

• With the pump assembled, the end cover

(122) removed (see 6.1 END COVER), and the

rotors (56) (see 6.2 ROTORS) and rotor case

(1) (6.7 ROTOR CASE) fully secured to the

correct torques.

• Measure the rotor front end clearances (c)

using a depth gauge or feeler gauge and

straight edge.

• If the clearance is incorrect (to Table 6 –

Rotor clearances) remove the rotors (56) (see

6.2 ROTORS).

• Remove the O-rings (31) and shims (30), the

shims are cut to allow them to slide over the

shaft.

• If mechanical shaft seals are fitted take great

care not to scratch, chip or damage the seal

faces.

• Measure the thickness of the shim pack for

each shaft and calculate the thickness of the

shim to add or remove on each shaft to give

the front clearance specified in Table 6 –Rotor

Clearances.

• Shims are available in increments of 0.025

mm (0.001 inch).

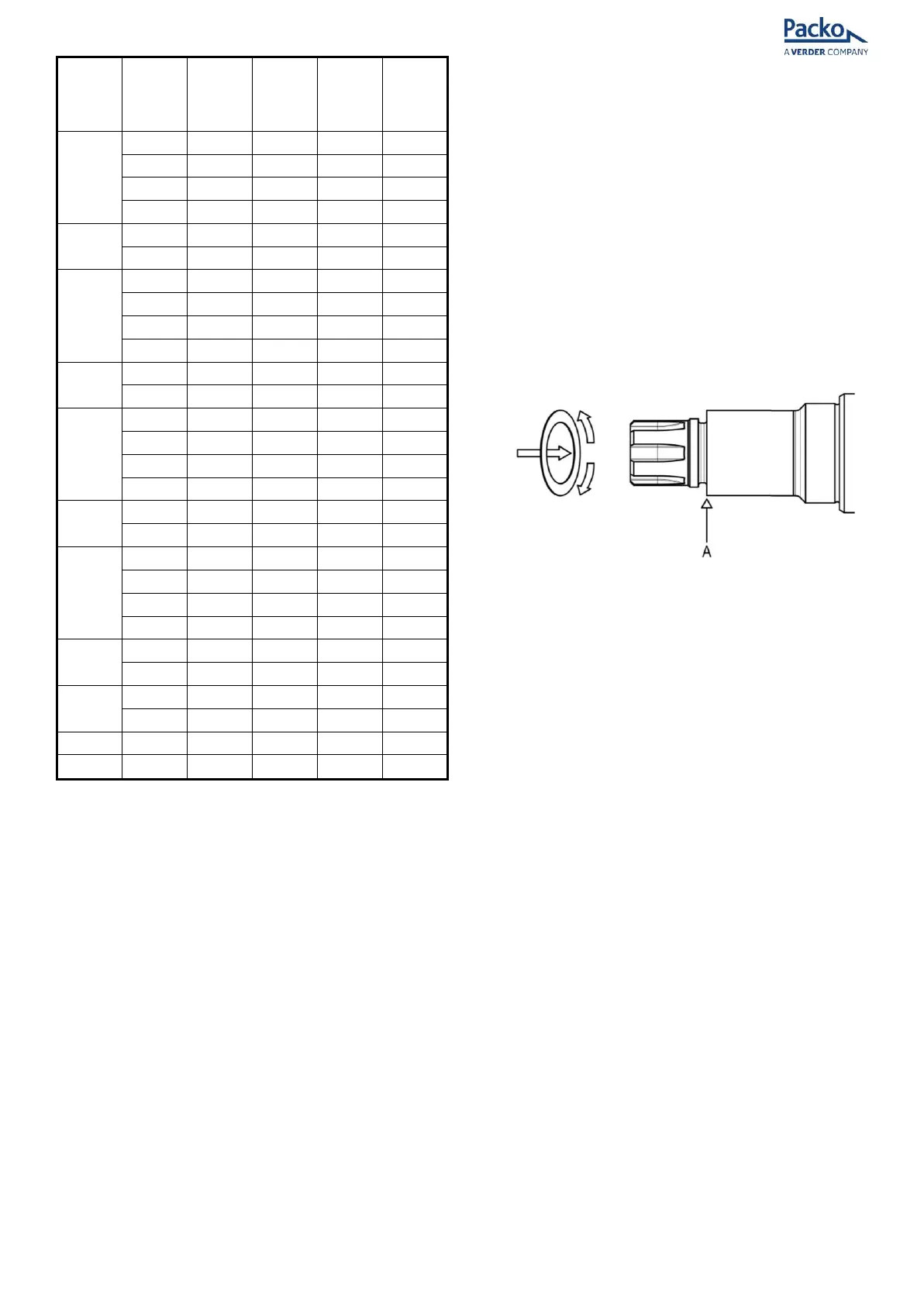

• To fit the shims open them slightly and slide

onto the shaft up to the shoulder (A) (Figure

32).

Note: On HP32 and HP34 tri lobe models splined

shafts are used with shim spacer rings (30a).

Shims are fitted between the shaft shoulder and

shim spacer ring.

Figure 32 - Fitting shims

Note: New shims are not cut; this will need to be

done with scissors prior to fitment if required.

• Fit the shims and retain them with the O-ring

(31).

Note: O-ring not used on HP32 and HP34 models

• Refit the rotors and tighten the retaining bolts

(59) to the correct torque (see 6.2 ROTORS).

Re-check end clearance and re-adjust if

necessary.

Check the condition of the bearings and the pre-

load if any side-to-side movement of the rotors

can be detected or if the radial clearance is

incorrect.

There is no adjustment for radial clearance -

replace the shafts and/or bearings if worn.

Meshing Clearance: Tri Lobe only

For Re-fitting or New Rotors:

• Gear nuts must be tightened to the

correct torque before taking clearance

measurements (see 6.14 BEARING SET-UP

Loading...

Loading...