35

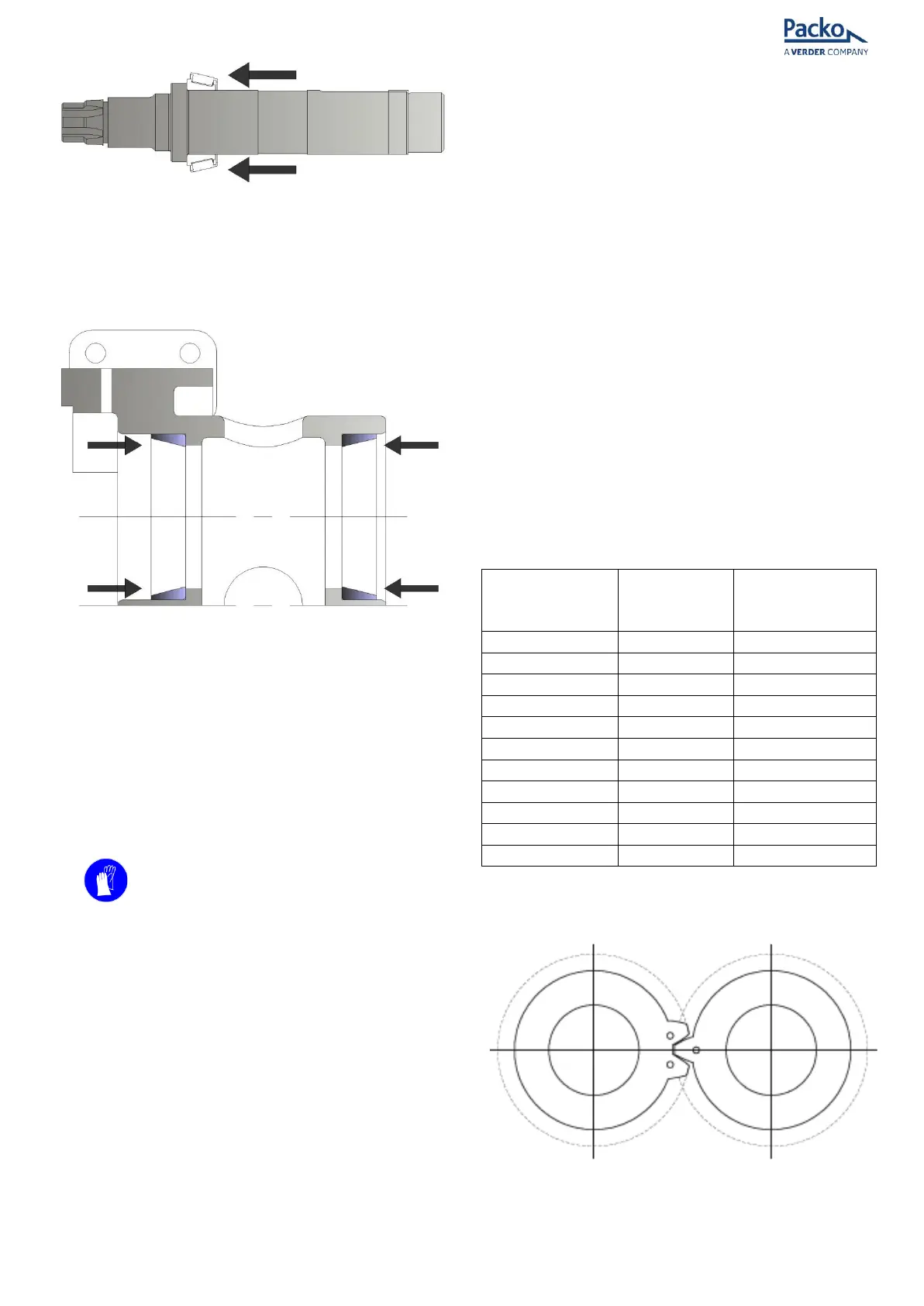

Figure 34 - Inner-ring fitment

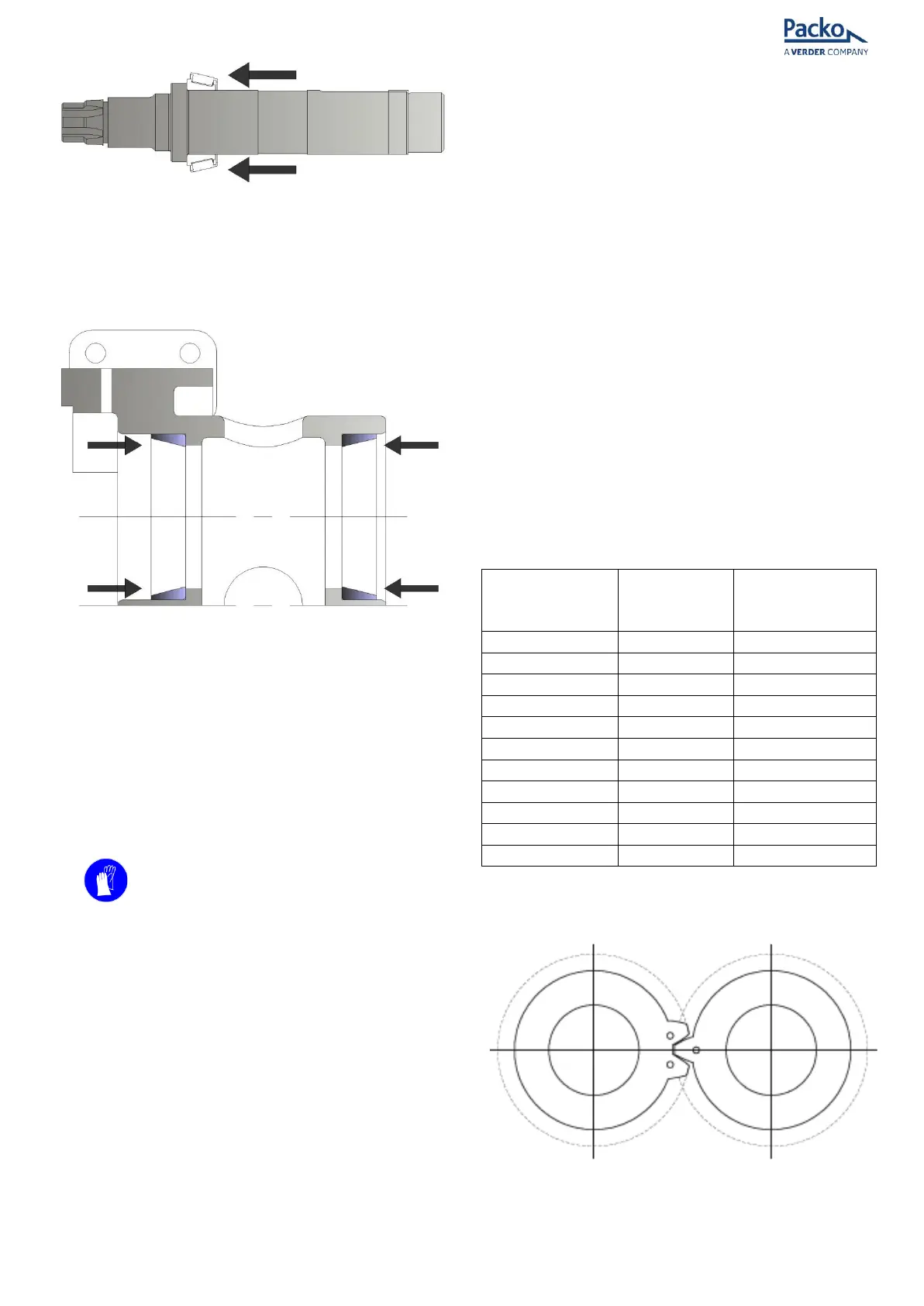

• Press both front (5) and rear (4) outer races

into the bearing housing, (Figure 35) making

sure they are square and pressed tight

against the bearing housing shoulder.

Figure 35 - Outer-ring fitment

NOTE: At this stage DO NOT put additional oil

on bearings.

• Stand shafts (24 & 25) on their front face and

lift the front of the bearing housing (1) over

them sliding the inner races of front bearings

(4) onto the shafts until the front inner

bearing races are in light contact with their

outer races.

ATTENTION

1. USE GLOVES: Heat inner races of rear

bearings (4) and assemble onto the shafts (24

& 25) making sure they are square and

pressed tight against the outer races in the

bearing housing. Ensure bearings are in the

correct orientation.

2. Put the bearing housing assembly (with shafts

in position) onto its feet.

3. Fit the gear drive key (28), gear (6), tab

washer (7) and gear nut (8). Tighten the gear

nut (8) by hand to hold the assembly in place,

taking-up any end float.

Note: To stop the shafts spinning the rotors can

be attached to the front of the shafts so a plastic

block can be placed between them as if you were

tightening the rotor screws. Alternatively a plastic

block can be inserted between the gears to stop

the rotors turning.

For all HP3, HP7 and HP8 sized pumps do not fit

the gear drive key (28), gear (6), tab washer (7)

and gear nut (8) yet. Use the second tab washer

(7a) and gear nut (8a) between the gears (6) and

the rear bearings (4).

4. Rotate the shaft a minimum of 4 times and

tighten the gear nut (8) again by hand.

(Bearing nut (8a) for HP3 models)

5. Rotate the shaft a further 4 times, tighten the

gear nut again by hand and then tighten the

nut a further quarter turn, using the C-

Spanner. (Bearing nut (8a) for HP3 models)

6. Rotate the shaft 4 more times and torque the

gear nut (8) (or bearing nut 8a for HP3

models)

7. Repeat two-three times until no further

tightening of the gear nut is perceived.

Loading...

Loading...