1) Put Center Gear Spacer on shaft of chassis.

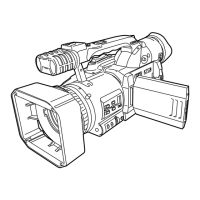

Fig.

A16-1

--

2) Put Center Gear on.

16 Pinch Arm & Center Gear

Fig.

A16-2

• 3) Make full loading position and put Pinch arm on, then put a washer on.

Fig.

A17-1

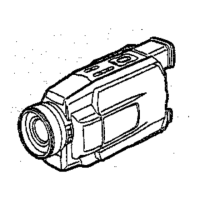

1) Make unloading position until moving Release Beetle

Confirm spring is exist.

Fig.

A17-2

2) Put Sub Chassis Unit on as pre-installation.

Fig.

A17-3

3) Tighten 3 screws.

Make Loading position until 1 screw position appears, then tighten a screw.

17 Sub Chassis Unit

Fig.

A17-4

--

4) Tighten a screws at Flex Holder portion and Hook spring back to Pinch Arm.

Fig.

A18-1

-- 1) Put Idler U into shaft of Drive Gear.

Fig.

A18-2

2) Put Cover Plate on and tighten 5 screws, then hook 2 springs to 2hooking

portion of Sub chassis.

And also put LED Flat Cable back.

18 LED Holder, Cover plate & Idler U.

Fig.

A18-3

--

3) Put LED Holder back.

Fig.

A19-1

-- 1) Confirm loading and unloading is smooth.

Fig.

A19-2

-- 2) Put Cylinder Unit & Spring on and tighten 3 screws.

19 Confirmation of Mechanism

movement , Cylinder Unit & RT Flex.

Flame.

FIg.

A19-3

-- 3) Put RT Flex. Flame on and tighten 2 screws.

Fig.

A20-1

1) Put H Amp Unit on and tighten a screw at bottom of chassis.

Fig.

A20-2

2) Connect Cylinder Flex to connector.

*20 H Amp Unit.

(Only Q1 & Q2)

Fig.

A20-3

--

3) Put Shield case on and tighten a screw.

Fig.

A21-1

1) Put both S &T sides to coupling portion on. 21 Cassette Up Unit.

Fig.

A21-2

--

2) Tighten 3 screws. (Q1 &2 have 4 screws)* 1)

Procedure 20 for H.Amp Unit is applied only Q1 & Q2

mechanism.

2) Procedure 1 - 3 can be changed in order.

The following parts should be applied Molyton Grease (VFK1024).

Loading...

Loading...