4 ASSEMBLY PROCEDURE

4.1 ASSEMBLY PROCEDURE

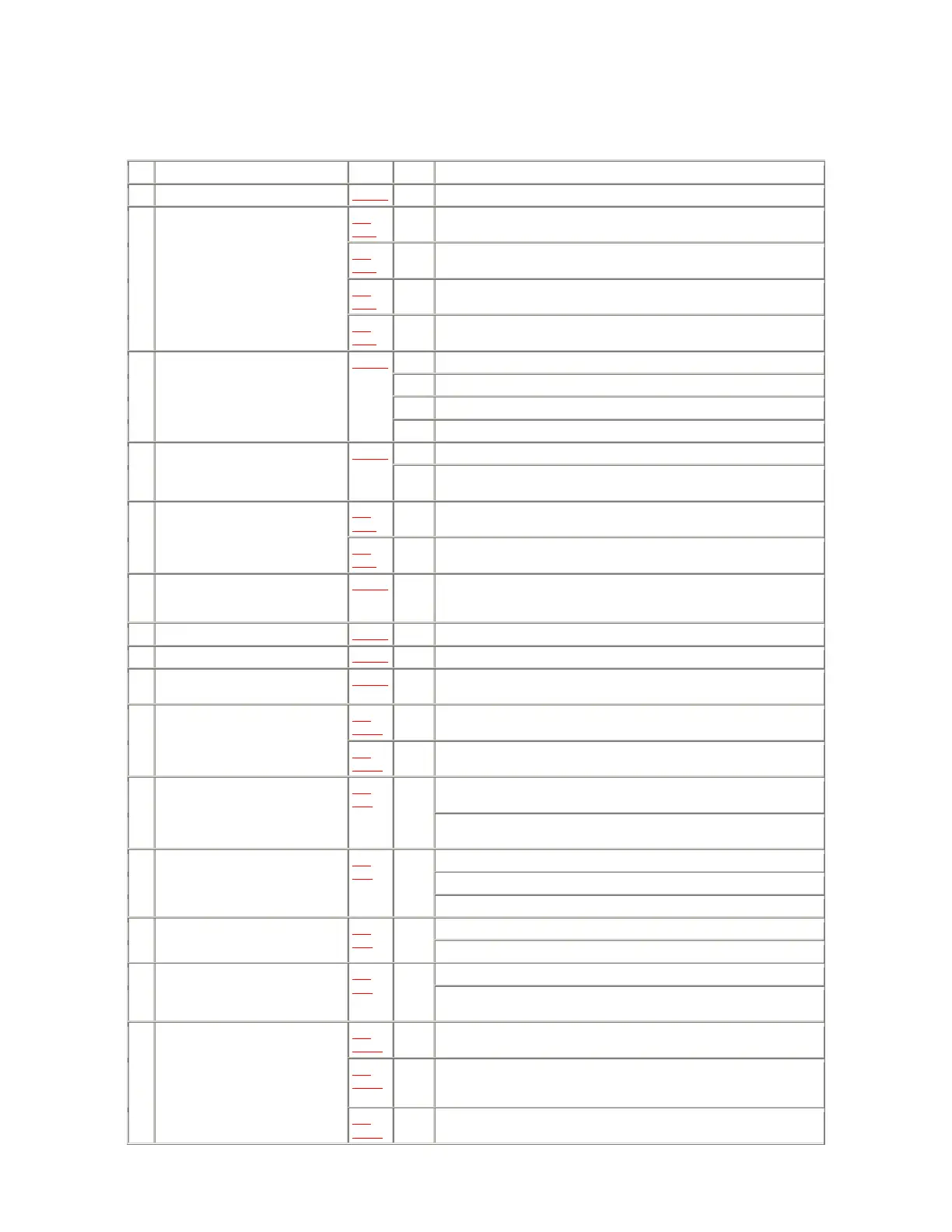

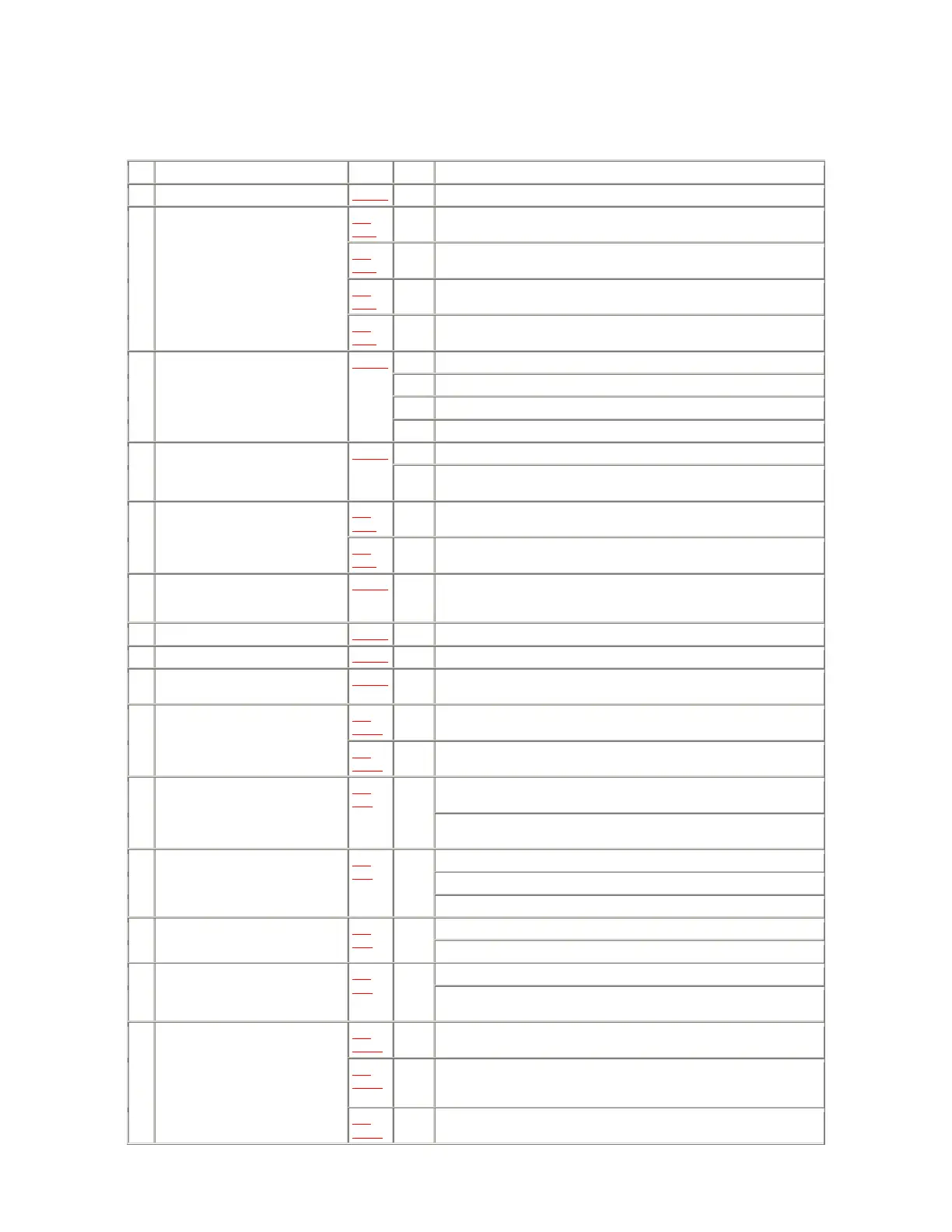

No. Item Fig. Grease Procedure

*1 S3 Base U. Fig. A1 -- 1) Put S3 Base U on and tighten a screw.

Fig.

A2-1

• 1) Put hole of T4 Guide to hole of chassis and tighten a screw.

Fig.

A2-2

• 2) Put Eject Lever on and a washer.

Fig.

A2-3

-- 3) Put boss of Pulley to hole of chassis on. Hole of chassis under pulley should

be visible through slit of Pulley.

*2 T4 Guide , Eject Lever, Pulley Cover

& Pulley.

Fig.

A2-4

-- 4) Put Pulley Cover on Pulley and tighten 2 screws.

• 1) Put Mode Sw on.

• 2) Put Deceleration Gear (B) on

• 3) Put Deceleration Gear (A) on and a washer.

*3 Mode Switch , Deceleration Gears &

Tension Plate.

Fig. A3

• 4) Put Tension Plate on and 2 washers.

-- 1) Put Loading Motor Unit on and tighten 2 screws. 4 Loading Motor unit & Mechanism

Interface Flex.

Fig. A4

-- 2) Put Mechanism Interface Flex on and tighten 4 screws. After that, solder at

terminal of Mode Sw.

Fig.

A5-1

-- 1) Put Capstan Motor on and tighten 3 screws.

Timing Belt should be between Pulley and boss.

5 Capstan Holder & Capstan Motor

Fig.

A5-2

-- 2) Put Capstan Holder on and tighten 2 screws.

6 Drive Gear Fig. A6 -- 1) Put a washer to shaft and install Drive Gear.

Timing Belt should be wound around Drive Gear. After that, confirm Timing

Belt and Gear are rotated together.

7 Boat Radon Fig. A7 • 1) Put hole of Boat radon to shaft of chassis.

8 Chassis Radon Fig. A8 • 1) Put Chassis Radon and a washer on.

9 Cam Gear Fig. A9 • 1) Put Cam Gear on. Phase Mark should be in the same line with chassis of

shaft..

Fig.

A10-1

• 1) Put Interface Gear(C) & (D).

Each phase mark should be in the same line.

10 Interface Gears

Fig.

A10-2

• 2) Put Interface Gear(A) & (B) on.

1) Put boss of Tension Lever into slit of Cam Gear and Tension Plate, then

tighten a screw.

11 Tension Lever & Eject Arm. Fig.

A11

--

2) Put boss of Eject Arm into slit of Cam Gear.

Put a washer on shaft of chassis.

1) Put boss of Pinch Beetle into slit of Mode Sw.

2) Put boss of Release Beetle into slit of Mode Sw.

12 Pinch Beetle & Release Beetle Fig.

A12

•

3) Put a washer on.

1) Keep sliding Gear Cover and put it on. 13 Gear Cover Fig.

A13

--

2) Tighten a screw.

1) Put S-Loading Gear on. 14 T-Loading Gear & S-Loading Gear Fig.

A14

•

2) Put T-Loading Gear on.

Each phase mark should be in the same line.

Fig.

A15-1

--

1) Make half loading until Connection Arm comes out.

Fig.

A15-2

--

2) Connect Arm of S & T Loading Gear and Connection Arms.

a) Hold Loading Gear side.

b) Push Arm of S & Tloading Gear into slit of connection arms.

15 Rail Unit

Fig.

A15-3

--

3) Tighten 4 screws.

Loading...

Loading...