3 - 19

2WAY SYSTEM

Outdoor Unit Repair Procedures

3

7. Charging Compressor Oil

(DPR : CV6230817937)

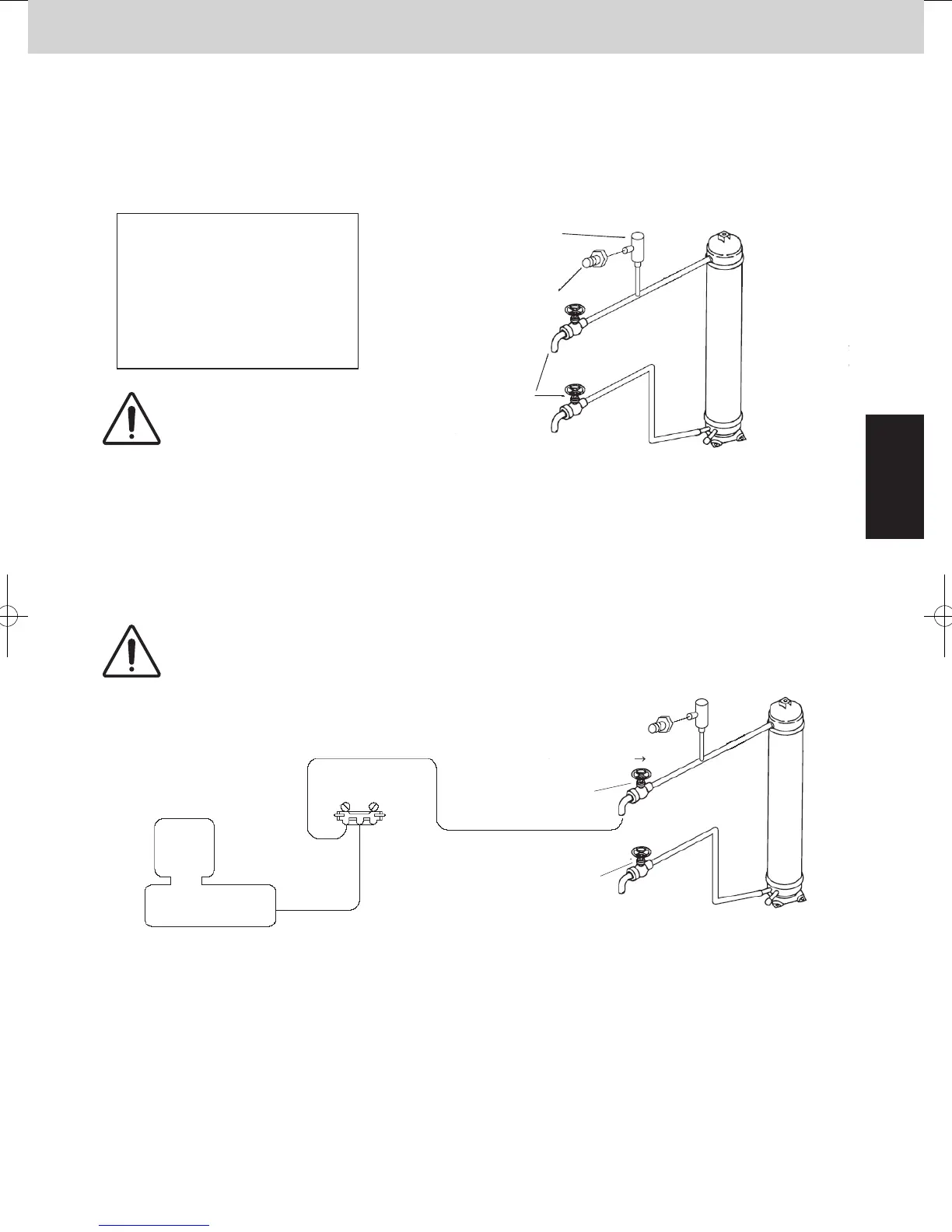

Nipple

Packless valve

(Receiver-tank:

CV6380152988)

Fig. 8

7-1. If Refrigerant Has Already Been Charged to Outdoor Unit

Be sure to use an exclusive oil-charging tank for charging compressor oil. Prior to charging, carry out vacuum drying

inside the tank and take care that no air (in the form of bubbles) is permitted to enter the tank.

The oil charging procedures are given below.

*The receiver tank used for maintenance may be used as an exclusive oil-charging tank.

When installing the oil-charging

tank to the refrigerant system to

serve as a safety bypass circuit

for refrigerant, connect it to the

gas tube service port carefully to

avoid releasing refrigerant into the

atmosphere.

Perform oil charging

work carefully so that no

liquid refrigerant enters

the charging tank.

CAUTION

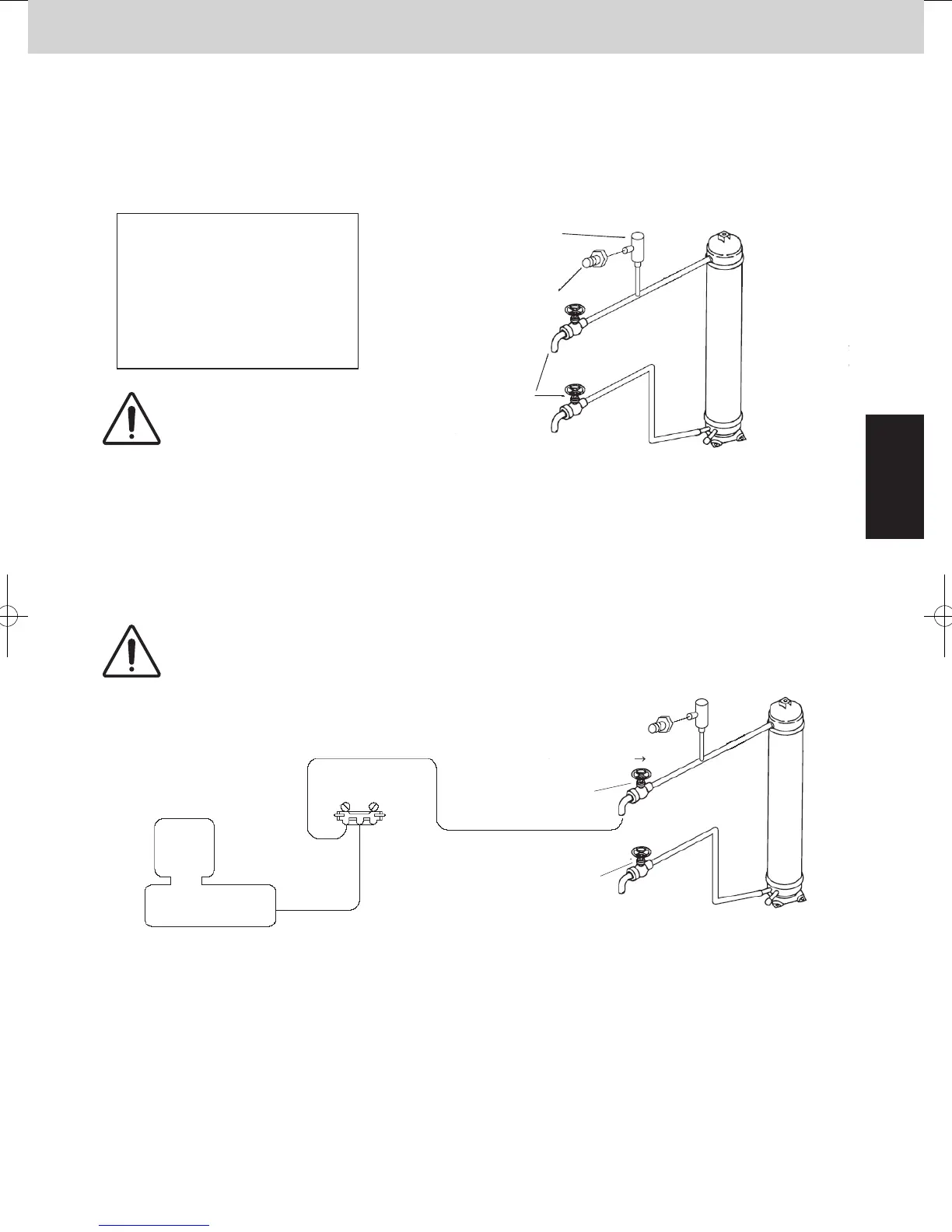

(1) Evacuation drying in oil-charging tank

With the lower side valve fully closed, open the upper side valve and connect it to the vacuum pump via the

manifold gauge valves as shown below. Run the vacuum pump and evacuate the tank until the pressure falls to

below –101kPa {–755mmHg, 5 Torr} for the evacuation drying. After the evacuation drying is finished, fully close

the upper valve. Next, fully close the manifold gauge valves and stop the vacuum pump.

To ensure proper evacuation, refer to the operating instructions that came with the

vacuum pump.

CAUTION

Lo

Hi

Manifold gauge

Open Close

Vacuum pump

Upper side

valve

Lower side

valve

Close

Fig. 9

(2) Charging compressor oil into oil-charging tank

Connect a piece of pipe to the lower valve and then insert the other end deeply into the bottom of the oil con-

tainer. Make sure you avoid letting any air be sucked into the tube. Next, run the vacuum pump and open the

manifold gauge valves, then open the upper and lower valves to begin charging oil into the charging tank.

SM830204-05_2WAY SYS_new.indb 19 15/01/05 15:31:35

Loading...

Loading...