14/1/98 Page 26 Issue H

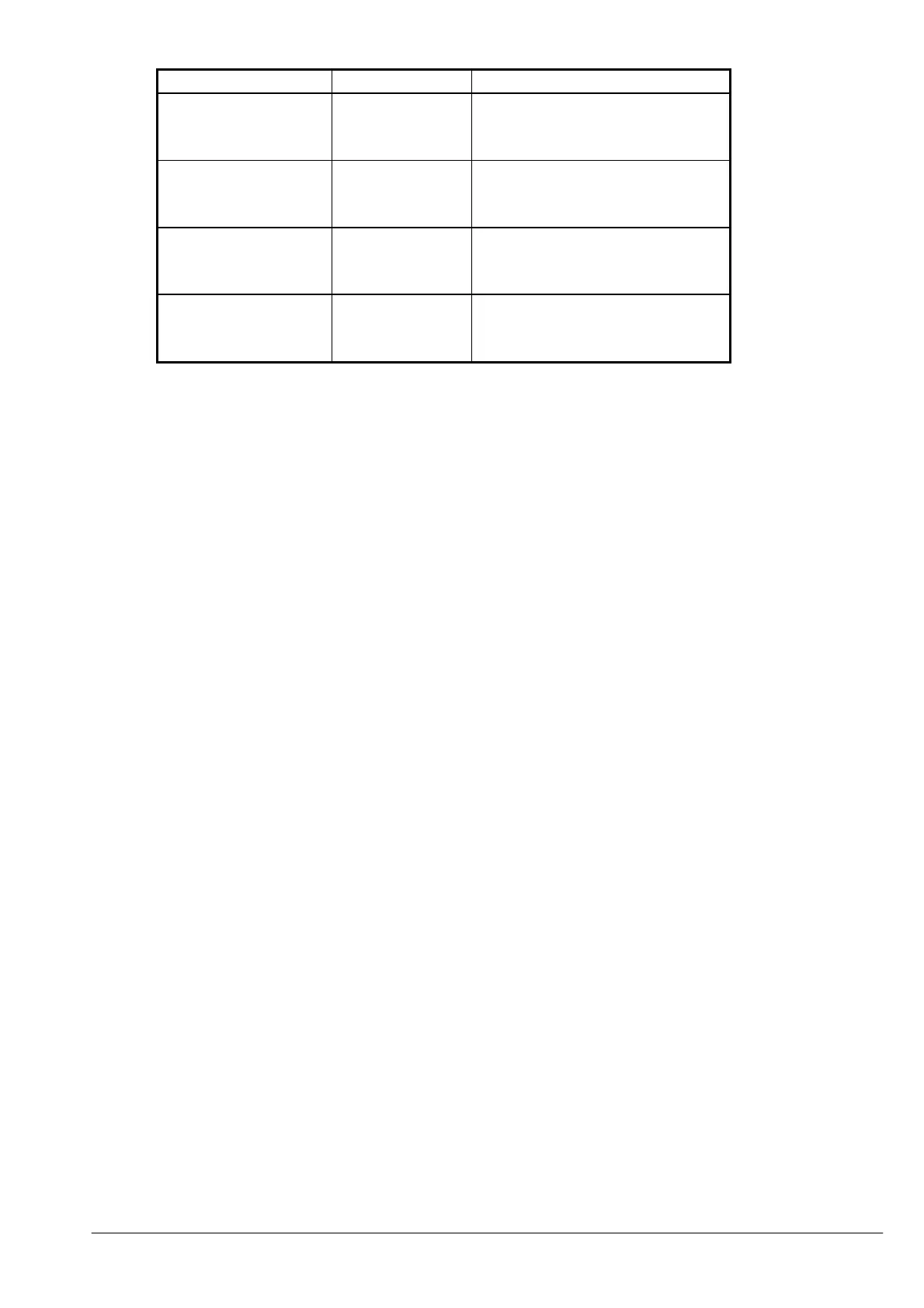

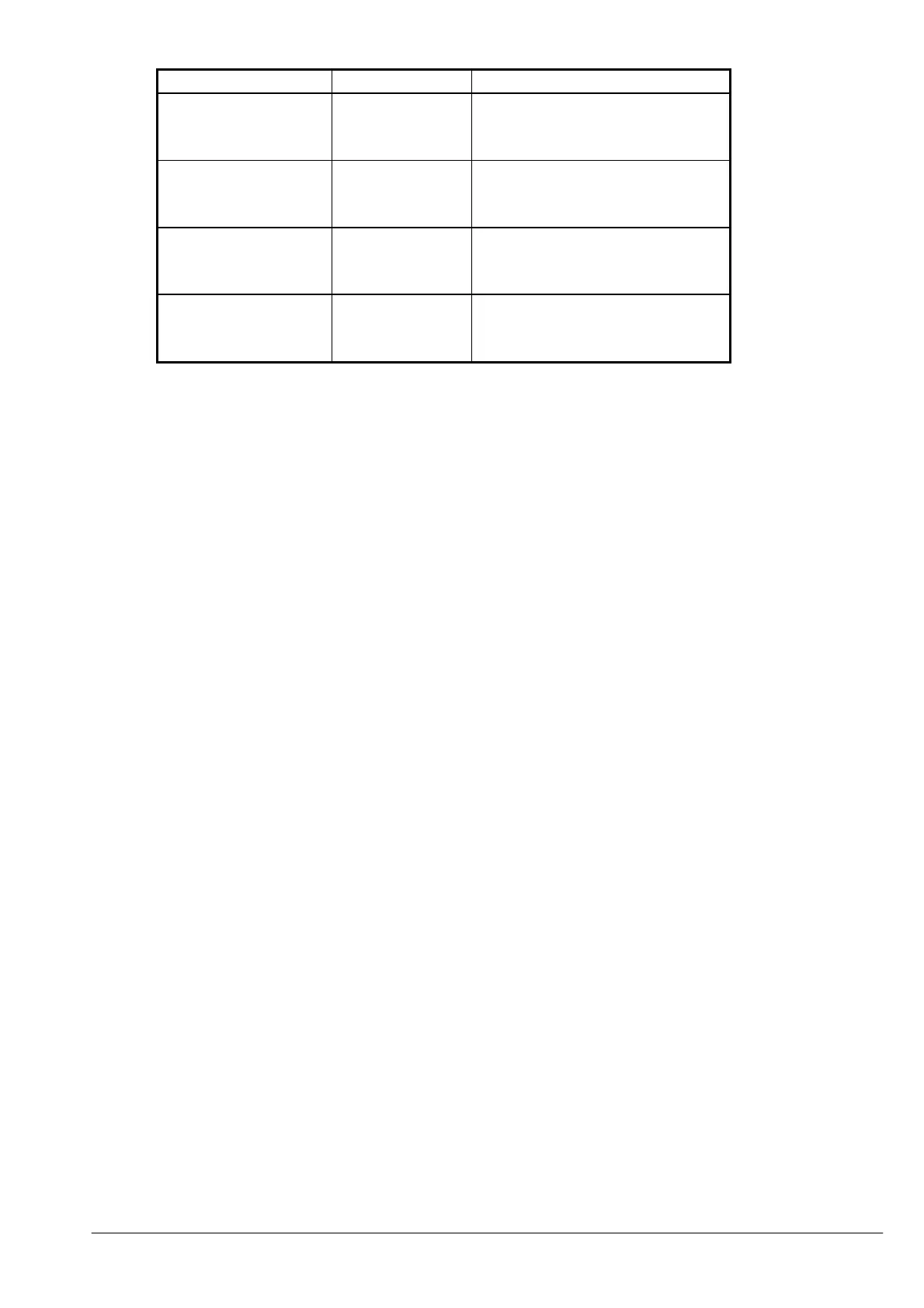

Relay Settings Test Current Nominal Operating Time

THERMAL

t6x = 10

I

FLC

= 0.5 x In

1.0 x In

3.0 x In

100.0 secs

10.0 secs

LOW SET

tI> =1.0

I> = 400% of FLC

4 x In

6 x In

1 sec--**

1 sec-**

HIGH SET

tI> = 0.5

I>> = 700% of In

8** x In

10** x In

0.5 secs

0.5 secs

EARTH FAULT

tIe = 1 sec

Ie =20% of In

0.3 x In

1.0 x In

1 sec

1 sec

Note -**

During starting the low set overcurrent is inhibited and the high set overcurrent is doubled.

If test current is applied to the relay from zero a start condition will be assumed, therefore the

test current must be applied from a running condition i.e. FLC and the trip time measured

from the instant the setting is exceeded.

Recommended Test Equipment - Available through P&B

Single Phase Secondary Injection - Sverker 750

Three Phase Secondary Injection - Freja RTS21

Primary Injection Test - up to 600A = 600 AT

- up to 2250A= ODEN/1x

- above 2250A = ODEN / 2x

Rapid Relay Test

A rapid relay test can be carried out with the relay in normal protective service. The relay test

consists of a check of incoming current values by entering Display Mode 1 and cycling through the

displayed values. This rapid test verifies that the energising and measuring circuits are operating

correctly.

Reset of Thermal capacity ( for test )

During testing, the thermal capacity may be reset to zero by removing the auxiliary supply, and then

re-energising the auxiliary supply whilst both the value up “ ∧ “ and value down “ ∨ “ buttons are

pressed.

Output Relay Test

By entering the test trip mode as detailed previously in this manual, the output relays may be

operated in a cyclic manor, testing the complete trip circuit.

Phase Rotation Test

This can only be tested with a 3 phase current injection test set with the phases 120° apart. (Single

phase injection will give spurious results.) The feature is only active during a start, therefore a

current higher than 150% FLC should be injected for a period greater than 10 sequence errors in a

row.

Loading...

Loading...