CHAIN

SPROCKET

Regularly

check

the

condition

of

the sprocket with

your

local retailer and replace

it

when it is worn.

Do

not mount a new chain with a worn sprocket

or

vice-versa.

SHARPENING

THE

CHAIN

(Flg.12)

AwAANINGI

To

ensure that the chain-

saw

worlor safely

and

fllficiently,

it

iJJ

fHllJIJlltial

that

the

cutting components are

welklharp-

ened.

Sharpening is necessary when:

• The sawdust looks like dust.

• Cutting becomes more difficult.

•

The cut is not straight.

• Vibrations increase.

• Fuel consumption increases.

AwARNINGI

II

the chain Is

not

suffi-

ciently

sharpened,

the

kick-beck's

risk

In-

creases.

A specialized centre will sharpen the chain using

the right

tools

to

ensure minimum removal

of

ma-

terial

and even sharpness on all the cutting edges.

If

you

sharpen the

chain

yourself,

use

special

round-section files with

the

right

diameter

de-

pending on the type

o1

chain (see "Chain Mainte-

nance Table"). You need a certain amount

of

skill

and

experience

to

avoid

damaging

the

cutting

edges.

Sharpen the chain

as

follows:

- Disassemble the pruner from the brush cutter

and secure the bar with the chain in a vice, so

that the chain can run

smoothly.

- Tighten the chain if it is loose.

- Mount the file in the guide and then insert it in the

tooth

at

a constant angle from the cutting edge.

- Sharpen in a forward motion a few times and

re-

peat this on all the cutting edges facing the same

way (right

or

left).

MAINTENANCE

AND

STORAGE

-

Tum

the bar over in the vice and repeat on all the

other cutting edges.

- Check that the

limiter tooth does not stick out fur-

ther

than

the

inspection instrument and file any

projecting parts with a

flat file, rounding

off

the

edge.

- After sharpening, remove

all traces

o1

filing and

dust and

lubricate the chain in an oil bath.

Replace the chain whenever:

-

The

length

of

the cutting edges reduces

to

5

mm

or

less;

- There is too much play between the links and the

rivets.

BAA

MAINTENANCE

(Fig.

13)

To

avoid asymmetrical

wear

on

the bar, make sure

it is turned over

periodically.

To

keep the

bar

in perfect working order, proceed

as follows:

- grease the bearings on

the

nose sprocket (if

present) with the syringe;

-

Clean the

bar

groove with the scraper (not in-

cluded);

- clean the lubrication holes;

- with a flat file, remove burr from the

edges

and

level off the guides.

Replace the

bar

whenever:

- the groove is not

as

deep

as

the height

of

the

drive

links (which must never touch the bottom);

- the inside of the guide is worn enough

to

make

the chain lean

to

one

side.

BAA

AND

CHAIN COMBINATIONS

Accessories with the following

code

must

be

used

on this machine:

11880175810 = bar (Length 25

cm/

1

o·

Groove width 1,27

mm/

1/20j

118801759/0 = chain (Pilch

318"

mini).

Given

product

evolution, the

above

mentioned

tools may

be

replaced in time with others having

similar interchangeable and operating safety char-

acteristics.

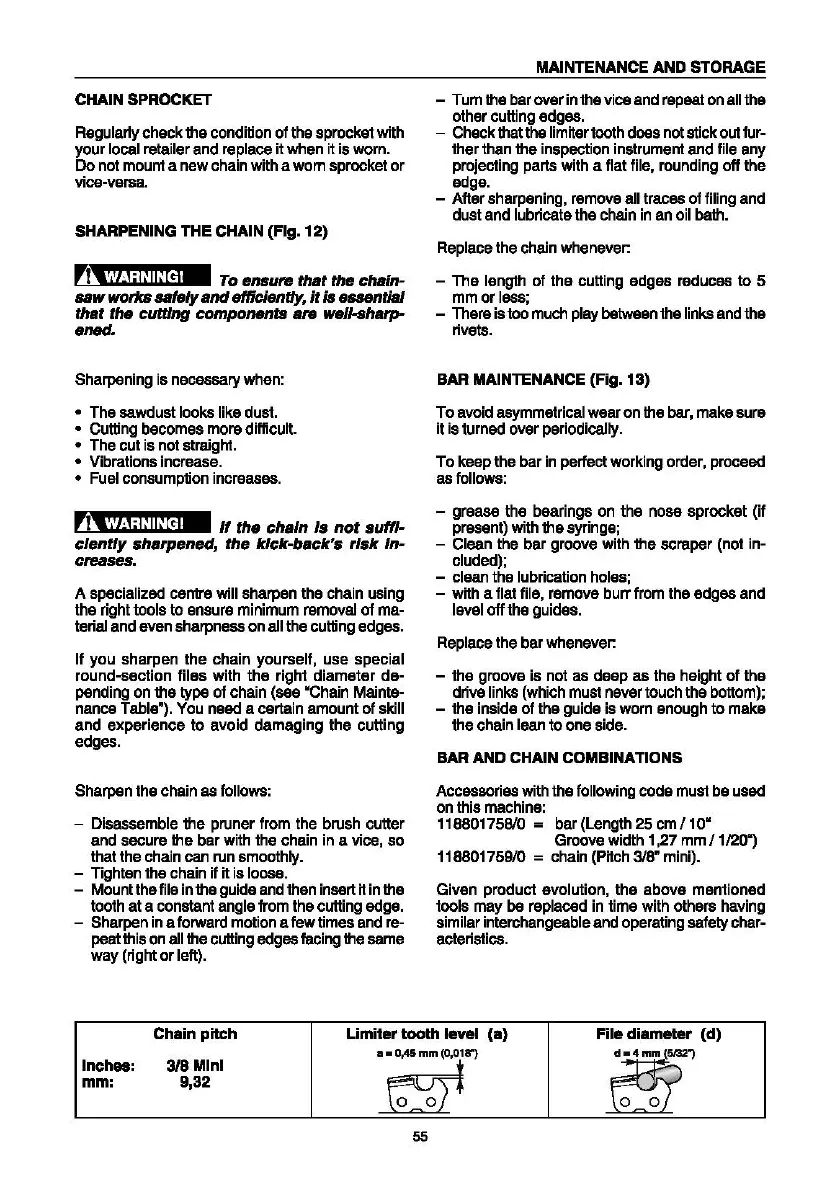

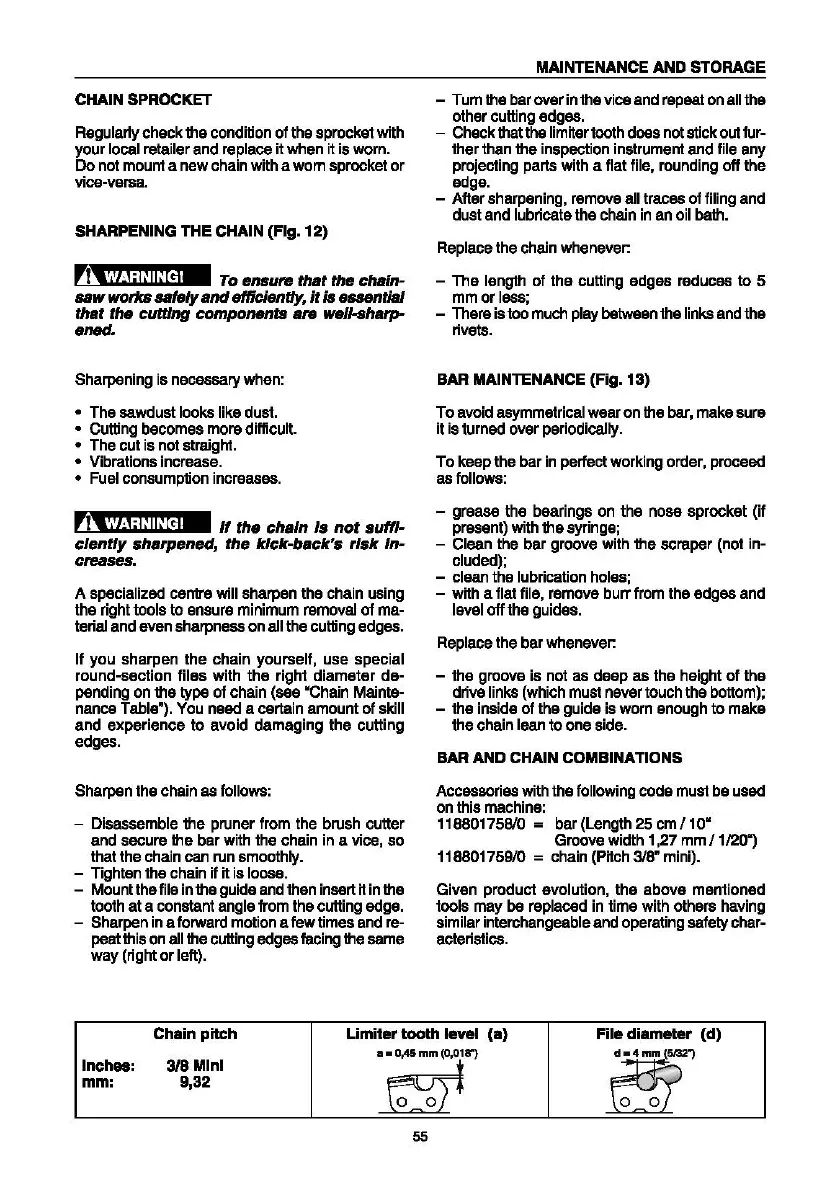

Chain

pitch

Limiter

tooth

level (a} File

diameter

(d)

d~

~

lnchee: 3/8 Mini

mm:

9,32

0

55

Loading...

Loading...