Copyright 2021 © Paragon Tank Truck Equipment

•

The use of Paragon brackets is recommended.

•

Should be strong enough to support the P657, accessories, and torque required.

•

Must allow minimum of 3/4” clearance between the blower and frame rail to prevent damage to the

blower.

•

Use Qty (4), 5/8” diameter bolts to mount the P657 Mounting Bracket to the tractor frame rail.

•

Paragon strongly recommends consultation with a local drive shaft specialist PRIOR to drilling the tractor frame rail.

•

At a minimum a drive shaft specialist should verify the following:

-

Required length meets industry standards for safe operation at the desired rpm.

-

Drive shaft is capable of operations for the required rpm.

-

Equipment slopes are correct to minimize torsional vibrations.

-

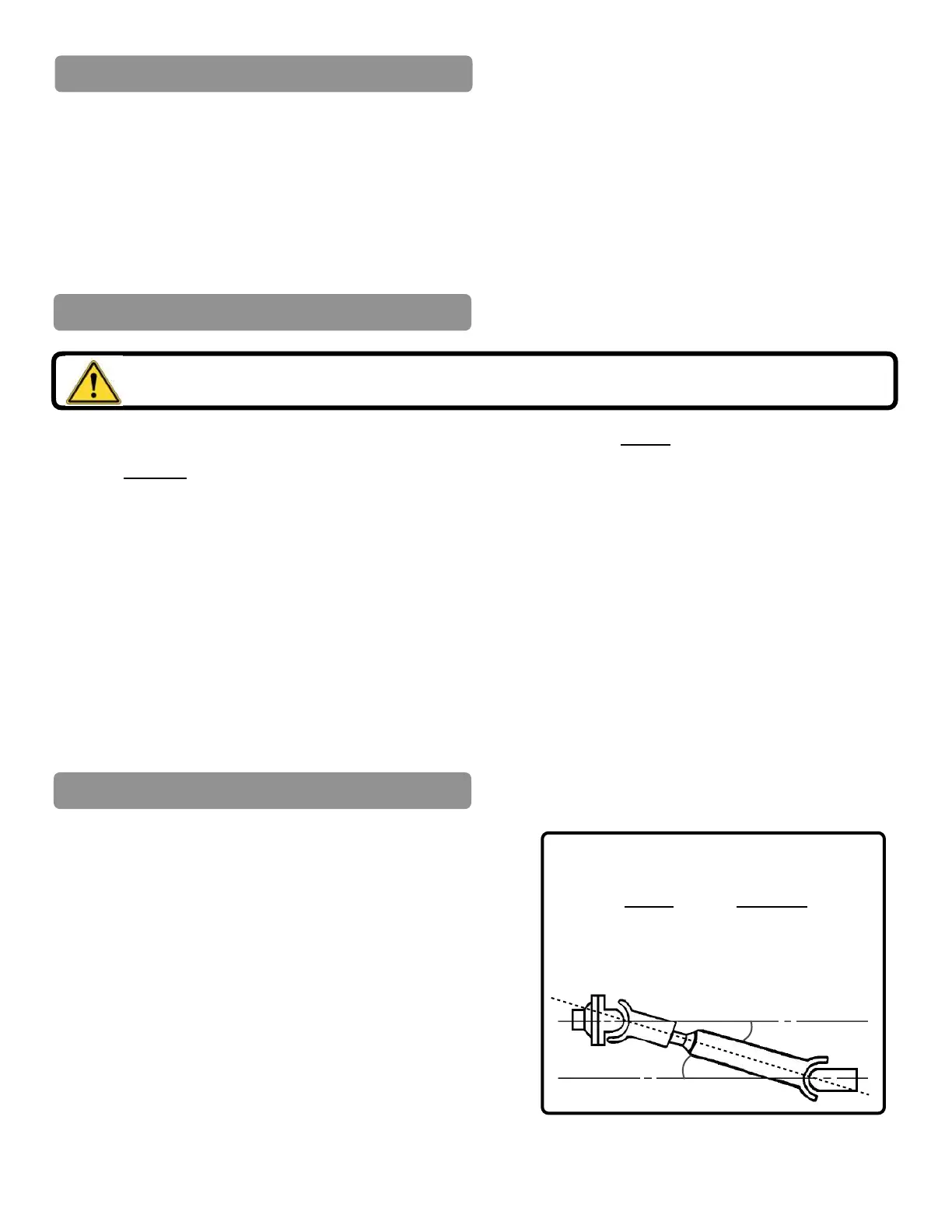

Confirm the drive shaft working angles are within industry specifications for safe operation(See Fig.4).

•

A minimum 3” diameter DOM Tubing x 0.083 wall thickness be used for P657 Blower applications.

•

That each drive shaft section has a “U” bolt hanger bracket for safety (See Fig.5, Page 8).

•

A minimum Drive Shaft critical speed of 2000 rpm.

•

Attach mounting bracket to the blower.

•

Torque mounting bolts to the required torque (77 lbs·ft)

•

Clamp the blower in place on the frame rail while

supporting the equipment from underneath.

•

Contact a drive shaft specialist.

Drive shaft and other components may shift with changes in suspension.

Maximum Drive Shaft Working Angles

Speed Angle “A”

2000 RPM 8°

1800 RPM 9.5°

1500 RPM 11.5°

1000 RPM 13°

Mounting Bracket Requirements

Determine Blower Mounting Slope

Loading...

Loading...