Axial Piston Pump

Series PV, series 47 and higher

Bulletin MSG30-3245-INST/UK

Installation manual

5

Parker Hannifin Manufacturing Germany GmbH & Co. KG

Pump & Motor Division Europe

Chemnitz, Germany

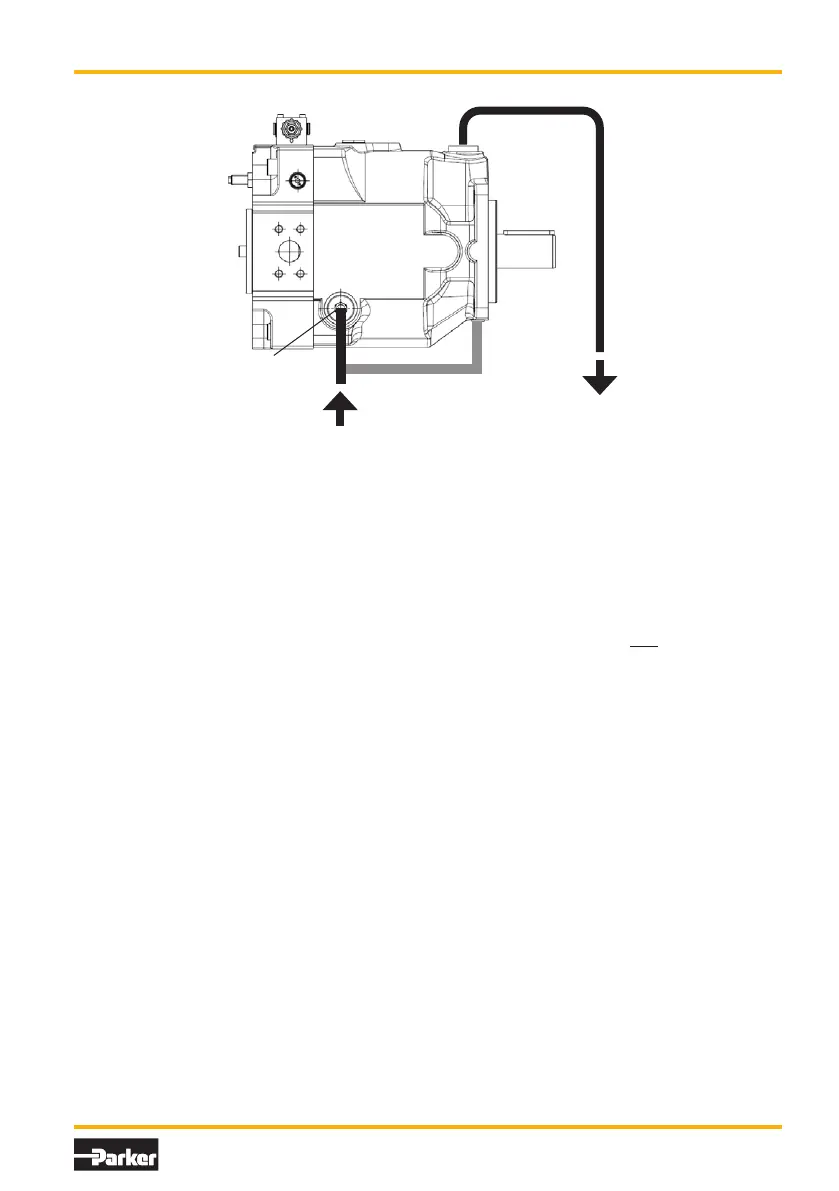

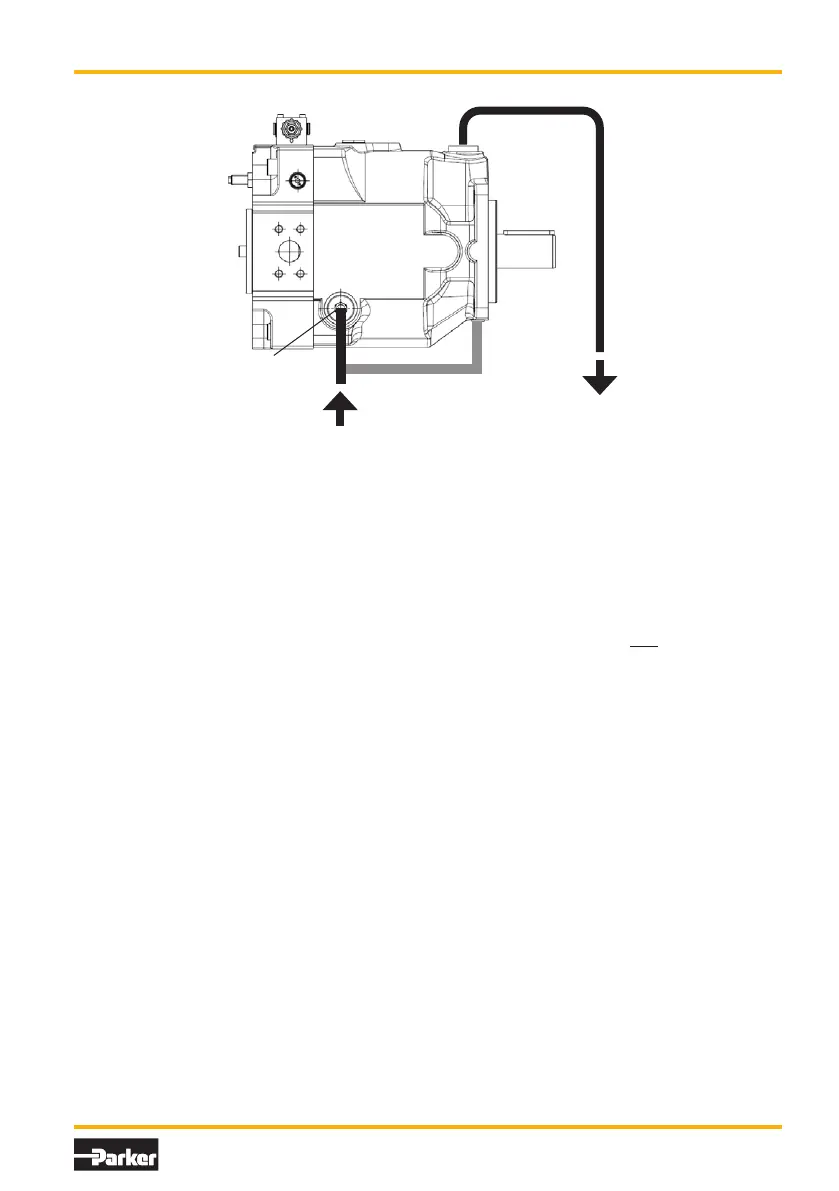

Flushing port

The PV pumps of design series 44+ are equipped

with three drain ports*. In addition all pumps are

equipped with a flushing port for front bearing

and shaft seal. The flushing flow can – depend-

ing on the actual working conditions – be used to

keep the pump case filled, to warm up the pump

(during cold temperature operation) or for better

heat dissipation e.g. for operation with HFC fluids

(water glycole) to keep the case fluid tempera-

ture in the allowed range. Permanent dead head

operation ( >15 min) either for pumps of frame

size 3 and larger (PV063 and higher) or at high

input speeds above 1,800 rpm requires flushing

of the pump case.

Flushing should be taken from the filter/cooling

circuit (e.g. pre-loaded return line). Recom-

mended flushing flows see following table.

PV016 – PV028 4 – 6 l/min

PV032 – PV046 5 – 8 l/min

PV063 – PV092 7 – 10 l/min

PV140 – PV180 9 – 12 l/min

PV270 – PV360 13 – 17 l/min

(flushing flow for front bearing: 10 – 15 % of the

total flushing flow)

Drive input

For direct drive use elastic coupling free of axial

and radial reaction forces. Please follow strictly

the instructions of the coupling supplier regarding

axial clearance, axial displacement and angular

tolerances. Couplings never shall be mounted

using a hammer. Threads in the shaft end allow

smooth mounting of the coupling.

The drive shaft should only carry true torque.

Contact Parker for allowable side loads or axial

forces.

PV pumps are normally for one direction of rota-

tion only. Therefore check rotation of drive motor

prior to installation.

Electrical interface

Check voltage, current, phase and connection

properties. Verify direction of motor rotation.

Fluid reservoir

The reservoir needs to meet all system require-

ments concerning design, size, location and

porting. Beside beeing reservoir for the hydraulic

fluid, the tank also supports heat dissipation,

air removal, water removal and contamination

sedimentation. Often the reservoir also is the

fundament for the motor pump unit. In this case

the separation of pump and remaining structure

by elastic means is mandatory to avoid noise and

vibration being induced into the frame work. The

reservoir needs to be carefully sealed against

ingression of contamination and water. A level

indicator and thermometer should be placed in

an easily accessible location.

Q

leak

Q

flush

L1

L4

L2/L3

Loading...

Loading...