3

Bulletin MSG30-8302-INST

Marketing information

Parker Hannifin

Pump & Motor Division Europe

Trollhättan, Sweden

Fixed and Variable Motors

Series F11/F12 and V12/V14/T12

INSTALLATION PROCEDURE

CONNECTION

Sensor wires are susceptible to radiated noise.

Therefore, the following shoud be noted:

• Uninterrupted screened 4 wire cable must be

used and the screen only connected to the

appropriate instrument screen input terminal or

0V. Connections to power earth are not

advisable.

• The sensor wires must be installed as far away

as possible from electrical machines and must

not run in parallel with power cables in the

vicinity.

The maximum cable length that can be utilized is de-

pendent on sensor voltage, how the cable is installed,

and cable capacitance and inductance. It is, however,

always advantageous to keep the distance as short as

possible. The sensor cable supplied can be length-

ened via a terminal box located in an IP20 protected

connection area (per DIN 40050).

Contact Pump & Motor Divsion Europe for

recommendations.

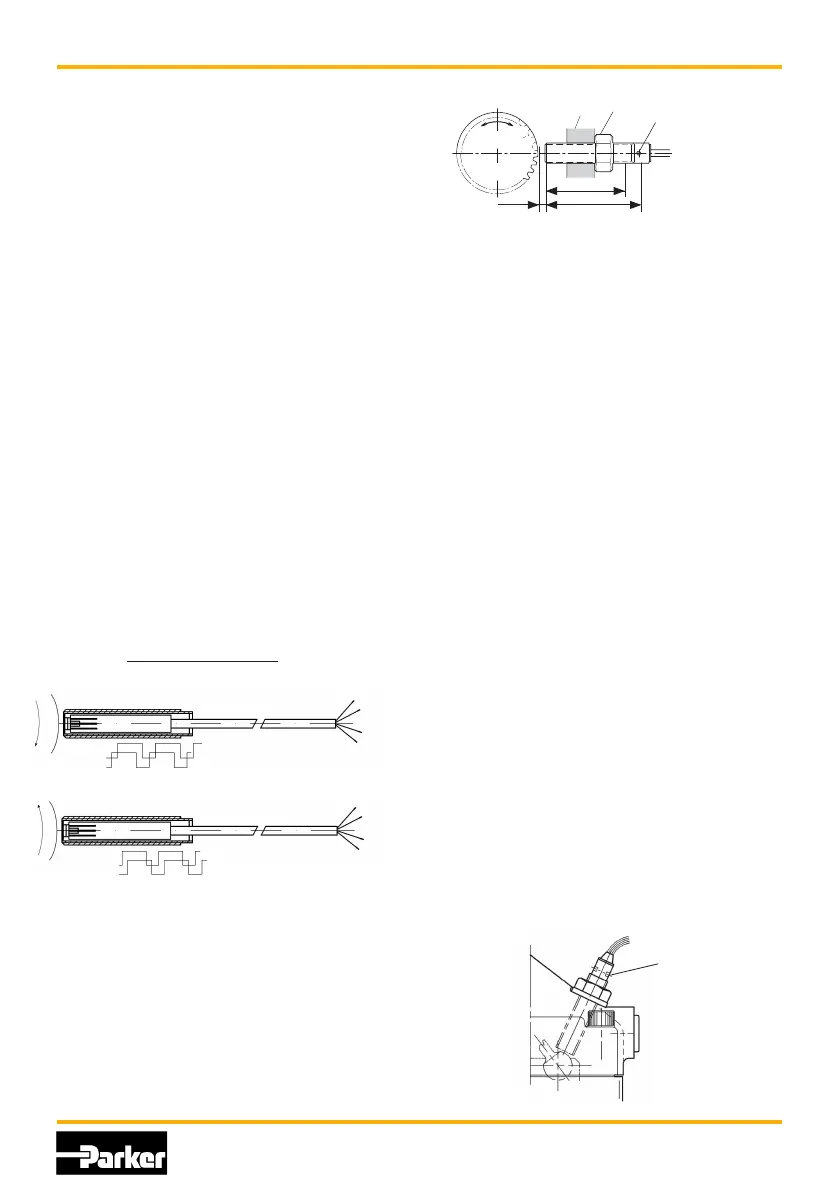

Connections and Pulse Diagram:

Direction of rotation

Speed sensor intallation, F12, V12,V14, T12

INSTALLATION INFORMATION

As the sensor has a built-in differential Hall effect

device, the sensor housing must be aligned according

to the drawing (Fig. 1& 2) of the Speed Sensor Instal-

lation picture. If it is not, the sensor may not function

properly and noise immunity decreases. The sensor

is non-sensitive to oil and the stainless steel housing

withstands hazardous environment conditions.

- Install the sensor in the threaded hole (M12x1) of

the F12/V12/V14/T12 bearing housing; turn the

sensor until its head just touches the ring gear

teeth (F12) or the shaft head (F12-250/V12/V14/

T12); refer to the installation drawing above.

- On *F11 the pistons positions must be known

before mounting the sensor. Install the sensor in

the threaded hole (M12x1) of the F11 barrel hous-

ing; turn the sensor until its head just touches the

piston.

- When mounting the sensor in the threaded hole be

sure that you also rotate the cable so the cable not

get twisted.

- Back off the sensor one turn (counter clockwise).

- If required, back it off further until the sensor

guiding hole centerline is as shown in Fig. 1 & 2 or

180° opposite.

- Tighten the seal nut; max 12 Nm (100 lb in). Be

sure that the position of the guiding hole centerline

still is correct.

- Connect the electrical wires as shown in the

schematic. Please note the instructions on

page 1 regarding screening.

- If you only use one signal, we recommend you to

use S2 cable. Cut S1 cable and isolate.

* F11: -6, -10, -12. -14, -19

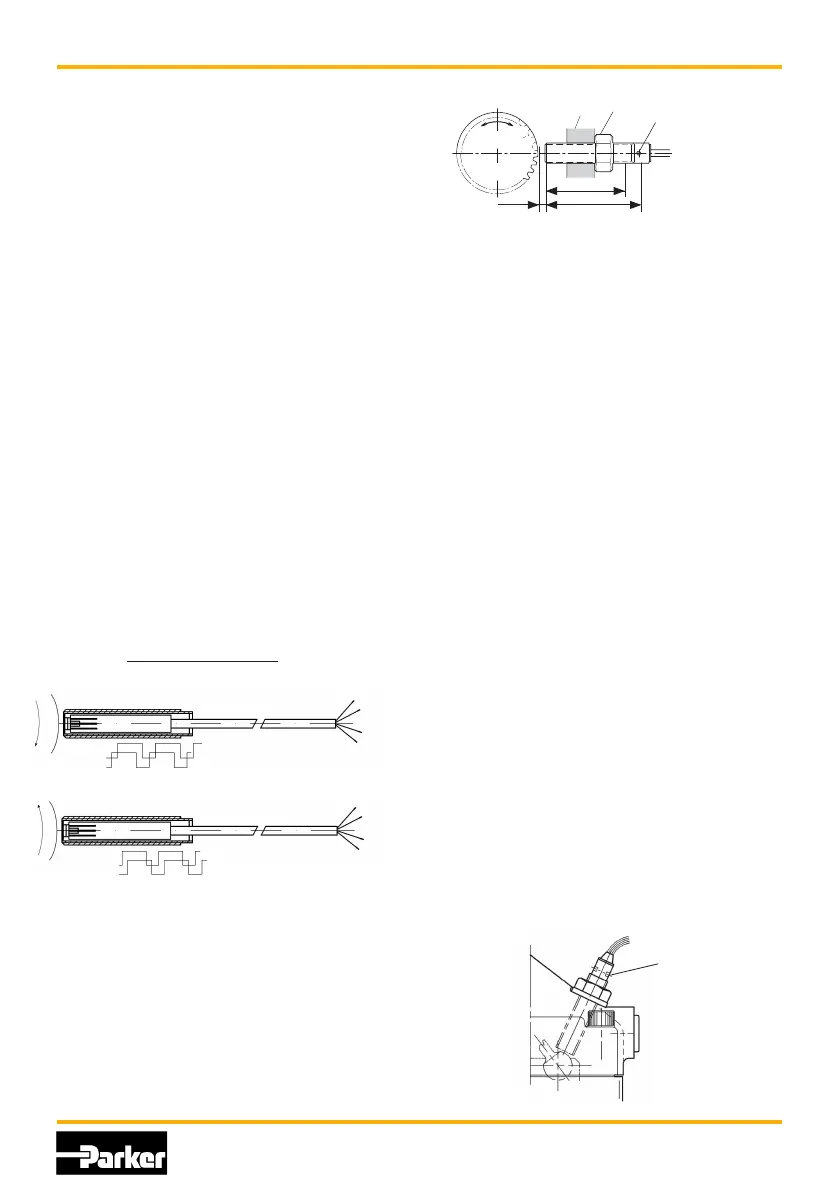

Fig. 1

Fig. 2

Depressions

(V12/V14 shaft head)

Ring gear

(F10, F 12)

0.1-2

50 [1.97]

63.4 [2.50]

Bearing

housing

Seal

nut

[0.004-0.78]

Rotation

RED - VDC

WHITE - S1

BLACK - S2

BLUE - GND

OUT I

OUT II

Rotation

RED - VDC

WHITE - S1

BLACK - S2

BLUE - GND

OUT I

OUT II

Sensor guiding hole

Sensor guiding

hole

Loading...

Loading...